1907-1909

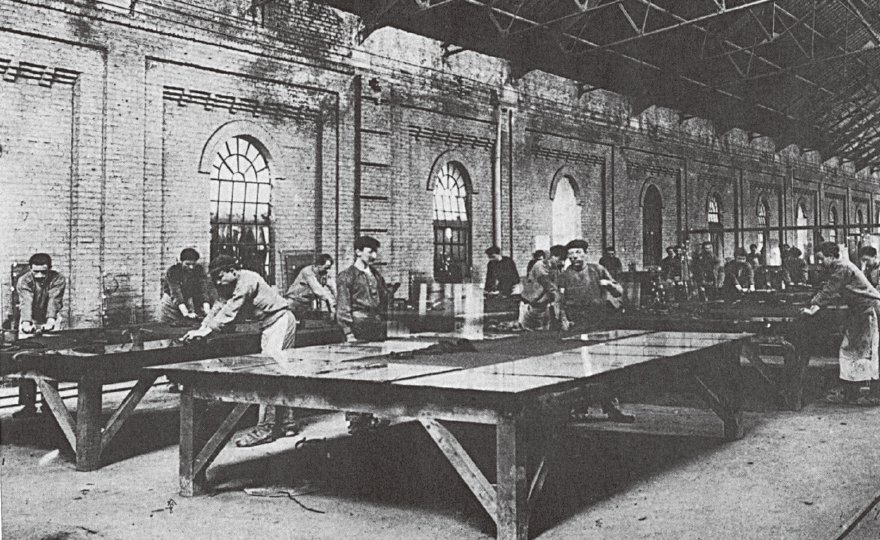

Producing Japan-made flat glass

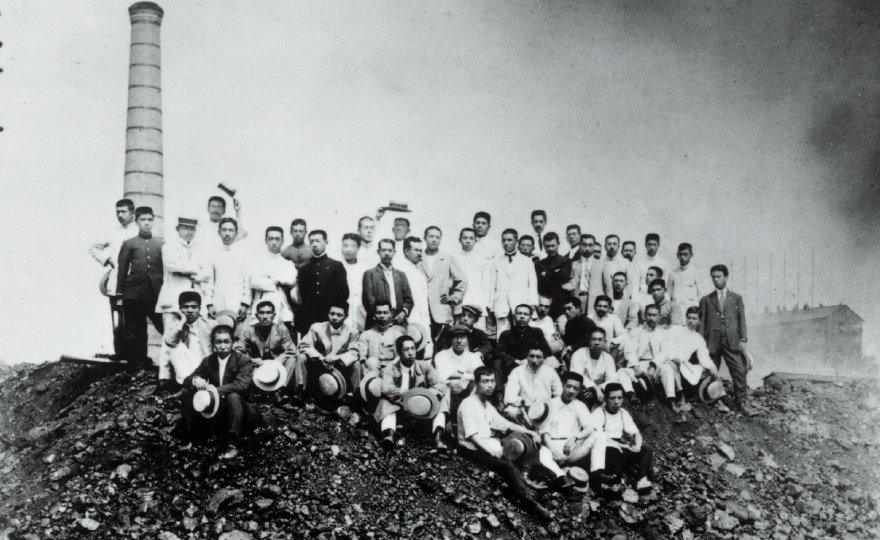

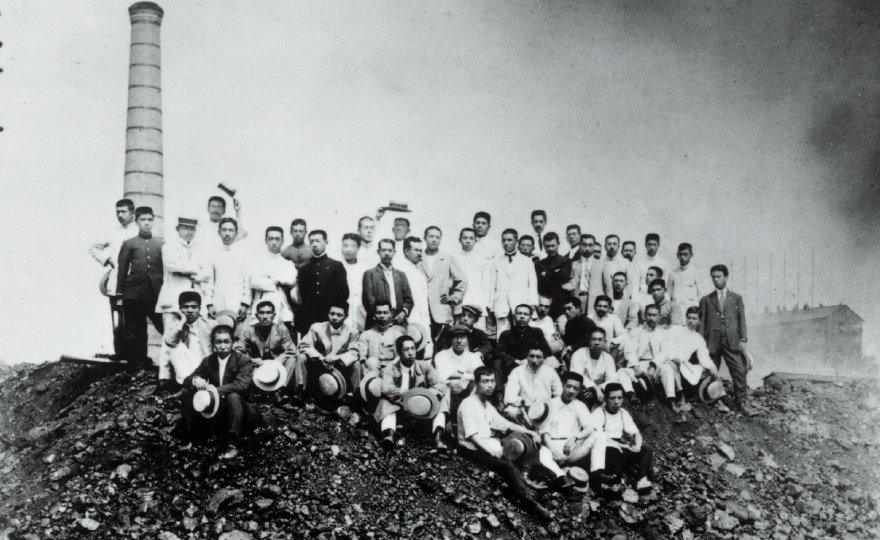

(Background) Tsurumi factory when Belgian hand-blown sheet glass manufacturing method was adopted

Chapter 1

Manufacturing flat glass for modernizing Japan

In 1907, Toshiya Iwasaki decided to start domestic production of flat glass and established Asahi Glass Co., Ltd. Despite numerous hardships, he grew the company into Asia’s largest flat glass manufacturer, and also expanded the business into production of soda ash and refractories, which were vital materials for flat glass manufacturing. With an indomitable spirit, he provided value to the country in various aspects.

Producing Japan-made flat glass

Contributing to the development of key Japanese industries

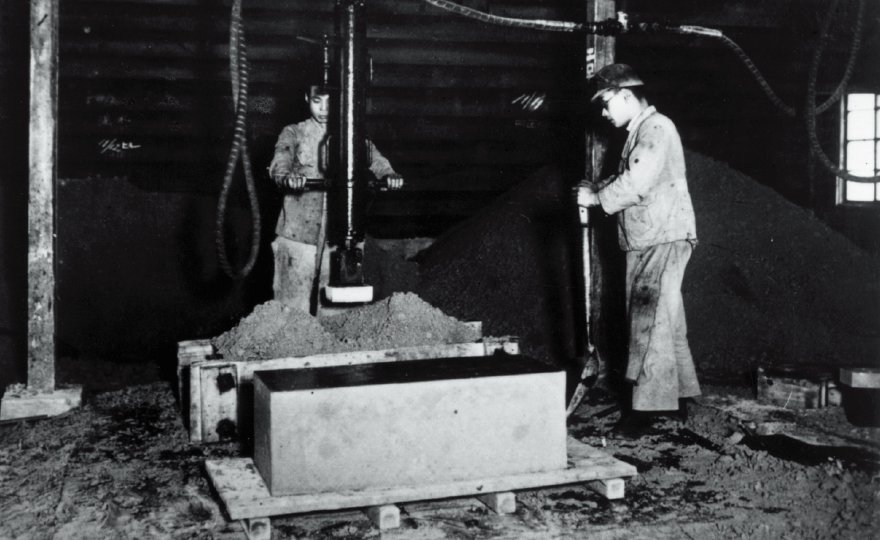

Refractories, an indispensable component in glass manufacturing, were mostly imported in those days. In order to ensure a stable supply of flat glass, AGC ventured into the refractories business. Its refractory business supported not only the development of AGC’s manufacturing activities but also the development of key Japanese industries such as steel and cement production.

AGC Ceramics Co., Ltd.Self-sufficient production of chemicals used in everyday life

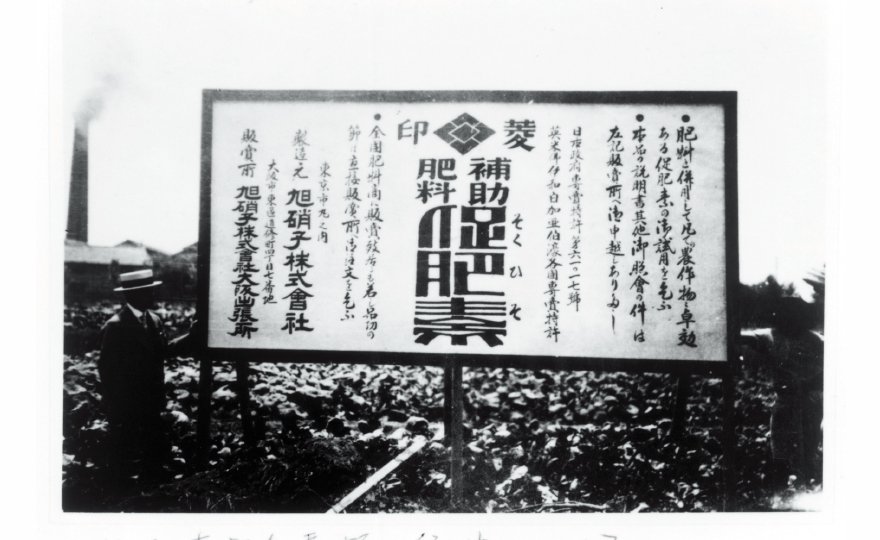

Due to World War I, AGC faced difficulties in importing soda ash, a raw material of flat glass. In response to this emergency situation, AGC developed the manufacturing process of soda ash on its own, and started the production. In addition to soda ash, AGC also sold sodium bicarbonates — a by-product of soda ash― for beverages and forcing fertilizer, thereby supporting peoples' daily lives.

Chemicals Business WebsiteThe origin of social contribution activities that continue for over 80 years

The Asahi Foundation for Chemical Industry Promotion (today known as the Asahi Glass Foundation) was established to commemorate the 25th anniversary of the founding of AGC. Since then, AGC has subsidized and supported research expenses for the development of the Japanese chemical industry.

Public interest foundation corporation The Asahi Glass FoundationChapter 2

Post-war recovery and a period of high economic growth

During the high economic growth period after the end of World War II, AGC responded to the escalating demand for skyscrapers, automobiles and color televisions. At the same time, AGC also worked to solve pollution problems caused as the harmful side effects of high economic growth.

From televisions to automobiles, supporting citizens' lives

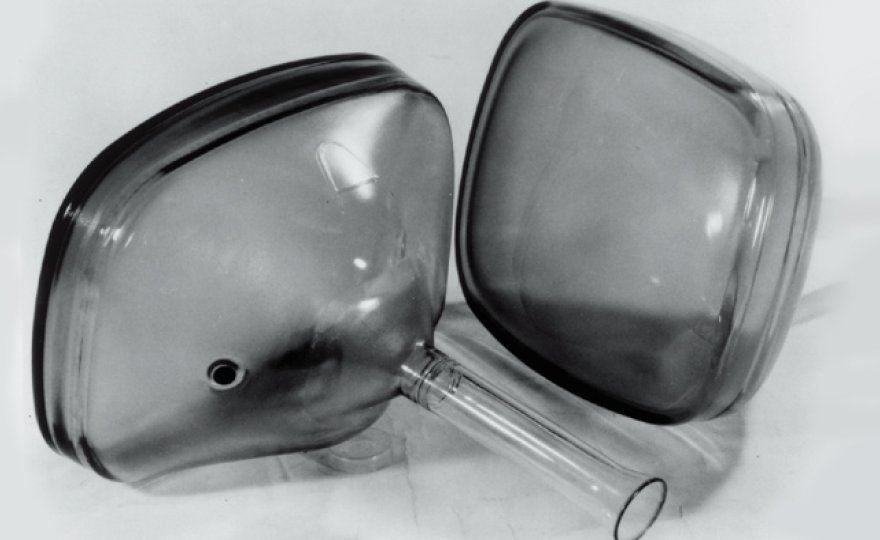

In the 1950s, NHK (Japan Broadcasting Corp.) began broadcasting. People gathered on a street and watched professional wrestling matches featuring Rikidōzan, Japan’s most famous professional wrestler, on televisions in the windows of stores. Before the automobile boom and television boom, AGC launched new businesses including the production of glass for automobiles and glass for cathode-ray tube (CRT) televisions. AGC’s glass made its appearance in everyday family gatherings, supporting lifestyles in the new era.

Products ProductsAssisted in the development of the Indian economy

In response to a request from the Indian government to help local companies, AGC established a production base in India earlier than any other Japanese companies, helping the development of the Indian economy.

Group CompaniesProviding products to make lives easier such as water-repellent spray and green houses for agriculture

Beginning with the manufacture of chloromethane and fluorocarbon, AGC entered into the fluorine chemical business. AGC also created hit products such as water & oil-repellent agents AsahiGuard™ and fluoropolymer film F-CLEAN™.

Chemicals Business WebsiteProviding a sense of affluence in everyday places such as buildings, homes, automobiles and railway cars

Due to a rush of construction projects for commercial buildings and private housing, the demand for flat glass increased. AGC’s float process enabled the production of large flat glass over 3m wide and 10m tall. AGC responded to the diversification of architectural styles.

Architectural Glass Architectural GlassSupporting people’s lives on the move with the Toyota Corolla’s success

Toyota Corolla, one of the passenger cars symbolizing the opening of the economy car era. Only AGC’s Kawasaki plant, with Japan’s first gas furnace, could produce the high quality side glass required for its design.

Automotive GlassChapter 3

Toward a stronger business structure & diversification, globalization

During the first oil crisis, AGC pursued the streamlining of and efficiency in production responding to material shortages and higher fuel cost. AGC achieved further growth by responding to needs in automobile production, the electronics industry and fluorinated products in the 1980s when the Japanese economy was recovering.

Taking over the glass manufacturing tradition from Belgium, and providing products to the Central and Eastern European markets

AGC acquired Glaverbel, a long-established Belgian glass manufacturer and the master of glass manufacturing technology for AGC. Taking over a traditional management spirit to always keep an eye on the global market, AGC expanded its bases in Central, Eastern and Western Europe. AGC also promoted the growth of Glaverbel and invigorated the market.

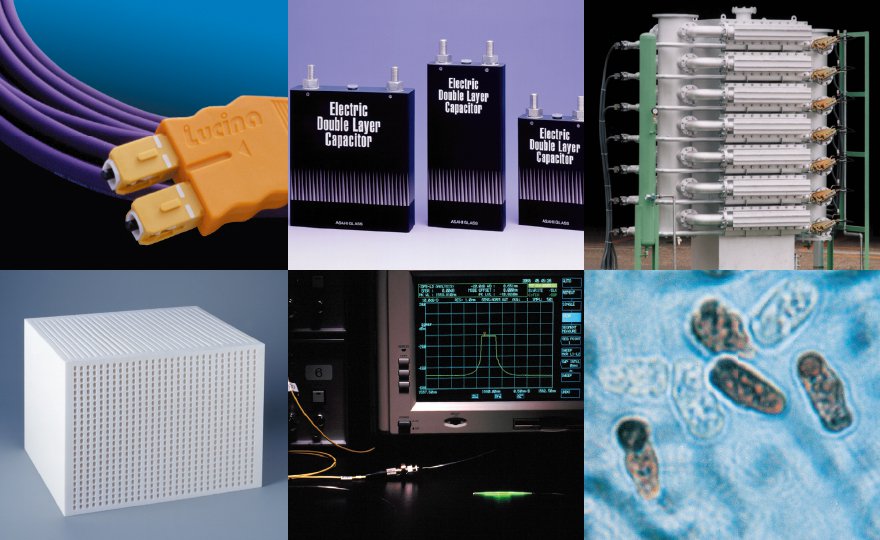

Group Companies Group CompaniesCorresponding with digitalization of information display devices

In the 1980s, AGC formed a professional team to develop an innovative glass melting technology. The knowledge and experience gained from the initiative eventually lead to development of glass for today’s smartphones and high-definition displays.

Electronic MaterialsContributing to regional development

AGC established AP Techno-glass company in Bellefontaine, Ohio, as a joint venture with the largest flat glass manufacturer in the United States. It won an award from the mayor for the contribution to the regional development through the production of automotive glass.

Protecting the ozone layer and the earth through new technology that amazed the world

In 1985, a huge ozone hole was found over the Antarctic Continent, leading to serious global environmental issues. In response, AGC developed an alternative to chlorofluorocarbon. ASAHIKLIN™ AK- 225 was highly evaluated in the world.

Chemicals Business WebsiteChapter 4

Growing into a truly global company

Amid the collapse of Japan’s bubble economy, AGC aimed to grow into a truly global company. Asahi Glass Foundation established an international prize for the global environment, the Blue Planet Prize, and AGC start production of alternatives to chlorofluorocarbon products to address environmental problems.

Doing what we can do for the future of the earth

In 1992, an international prize for the global environment, the Blue Planet Prize was established to honor the works of individuals and organizations who contributed to solving global environmental problems. Over the years, Asahi Glass Foundation has continued to aid such endeavors.

Asahi Glass Foundation Blue Planet Award Asahi Glass Foundation Blue Planet AwardDelivering new excitement through televisions with new technology

As the world entered the large-screen TV boom, AGC developed TLIPRED™, the world's first large flat panel for CRT televisions. It was used in Sony’s WEGA line of TVs, contributing to wonderful entertainment experiences for consumers.

From proteins to environmental protection

AGC supplied material solutions in promising new fields such as optoelectronics, life science, environment and energy. AGC continued to supporting changing daily lives.

Chapter 5

Contributing to diversified lifestyles

AGC developed new products such as glass for digital devices for ever-changing lifestyles. In 2015, AGC established its management policy AGC plus, committed to providing additional value for various stakeholders. Since 2016, AGC has been pursuing its long-term strategy “Vision 2025” by reinforcing and expanding its core businesses and strategic businesses.

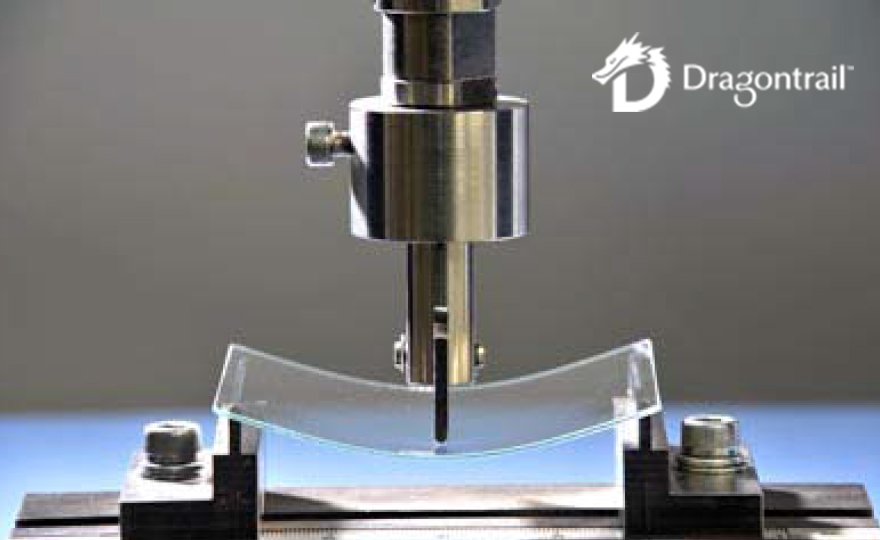

Helping you protect your smartphone and devices from scratches and shocks

AGC began sale of Dragontrail™ — thin, strong and light-weight specialty glass for chemical strengthening for electronic devices. AGC supports modern lifestyles through the cover glass of mobile devices and smartphones.

Dragontrail™Protecting drivers from UV rays

Launched the world’s first 99% UV-blocking tempered glass for automobile doors. It protects the skin of drivers and passengers, ideal for those concerned about getting sunburn while driving.

99% UV cut glass 99% UV cut glassMaking everything around you a display screen

AGC developed infoverre™, a space-saving display attached directly on the glass, and Glascene™, a transparent glass screen. In various locations, glass plays a new role as an interface for transmitting information.

New business developmentComfort in using touch panels

SURECO™ is a high-abrasion resistant & anti-fingerprint coating which makes it easy to wipe off fingerprints. Coating SURECO™ on cover glass for a touch panel, lens or mirror (including plastic and metal) prevents stains and will make people’s lives easier.

Chemicals Business WebsiteAGC has created value by responding to the changing periods and peoples’ needs. Even now at this moment, AGC, with an indomitable spirit, is generating new benefits for the future.

Vision 2030