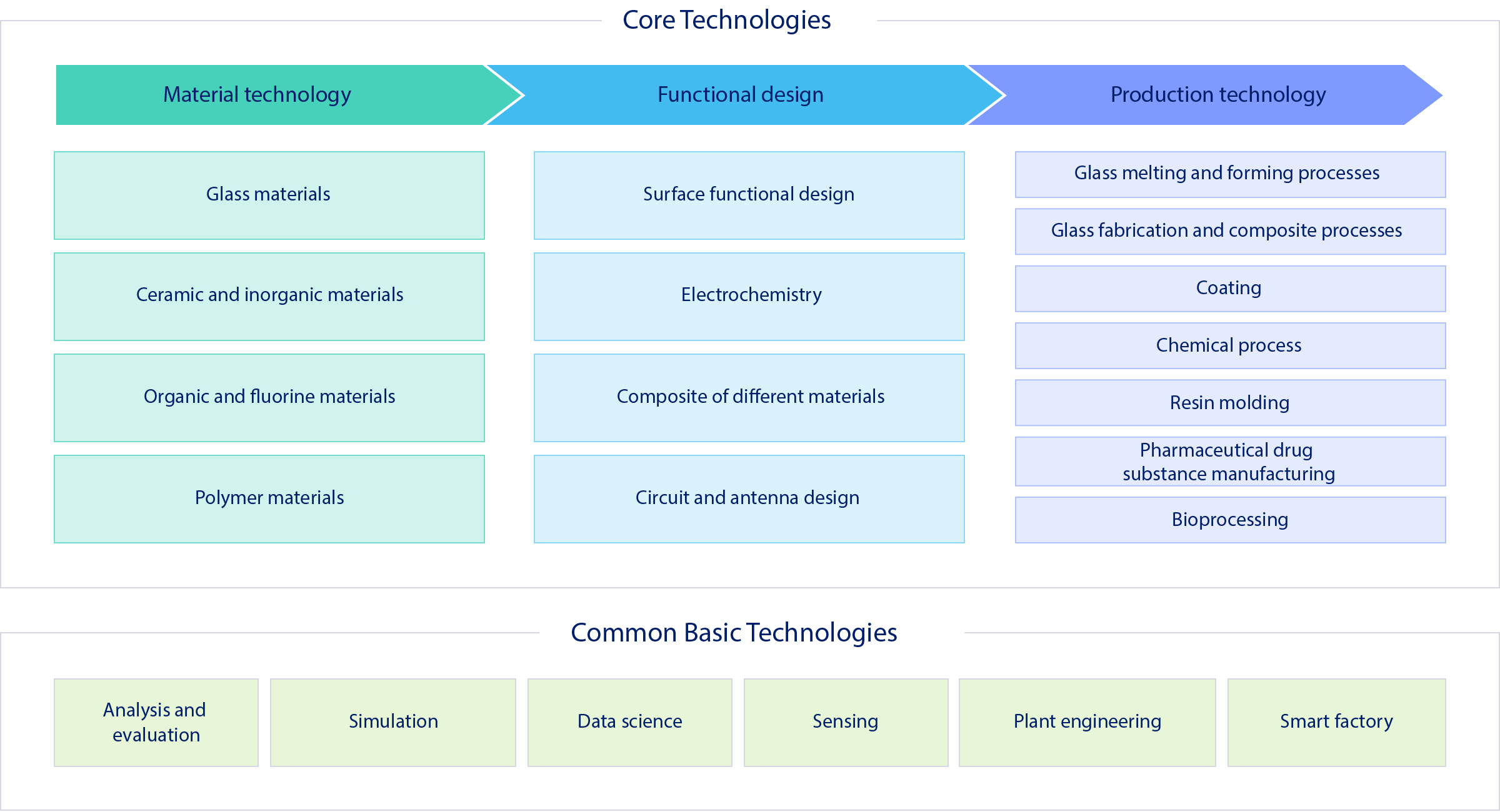

Core Technologies

Common Basic Technologies and Core Technologies

AGC's shared core technologies have been accumulated and deepened over many years. They include highly sophisticated materials technology, functional design technology that yields enhanced functionality through convergence with materials technology, and production technology that enables stable production of high-quality products. Through our efforts to meet customers' expectations and our experience of utilizing various materials, we have also accumulated technologies for designing parts by assembling various materials. We use these technologies to bring out the full potential of materials.