August 30, 2018Products

AGC to Make Drastic Expansion to Production Capacity for Fluon+ EA-2000 Fluorinated resin, a Material Used in 5G High-Speed High-Frequency Printed Circuit Boards

AGC, a world-leading manufacturer of glass, chemicals and high-tech materials, has decided to make drastic expansion to its production capacity for Fluon+ EA-2000 fluorinated resin by establishing a new production facility in Japan. Fluon+ EA-2000 is primarily used as a material for 5G*1 high-speed high-frequency printed circuit boards. In response to expectations for a sharp increase in demand associated with the full-scale practical application of 5G in 2020, AGC will set up a new supply framework for the product at its Chiba Plant. The operation will begin in September 2019.

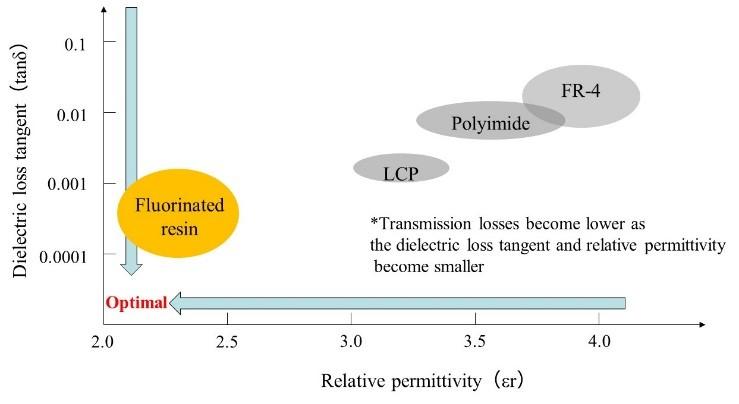

With the arrival of the IoT age in which everything will be connected to the Internet, the operation of 5G is expected to begin around the year 2020. CCL*2 is a material used in printed circuit boards intended for 5G applications with high-frequency bands, and its production in turn requires materials with low transmission losses*3.

AGC’s Fluon+ EA-2000 fluorinated resin preserves the outstanding characteristics of fluorinated resin including its thermal resistance and electrical properties, while also adding adhesive properties and dispersibility. Use of this product in printed circuit boards can reduce transmission losses by over 30% compared to existing materials (comparison at 28GHz band). Its exceptional adhesive properties and dispersibility also make it possible to utilize the low transmission loss characteristics of fluorinated resin regardless of customer processing formats.

AGC’s Fluon+ EA-2000 fluorinated resin preserves the outstanding characteristics of fluorinated resin including its thermal resistance and electrical properties, while also adding adhesive properties and dispersibility. Use of this product in printed circuit boards can reduce transmission losses by over 30% compared to existing materials (comparison at 28GHz band). Its exceptional adhesive properties and dispersibility also make it possible to utilize the low transmission loss characteristics of fluorinated resin regardless of customer processing formats.

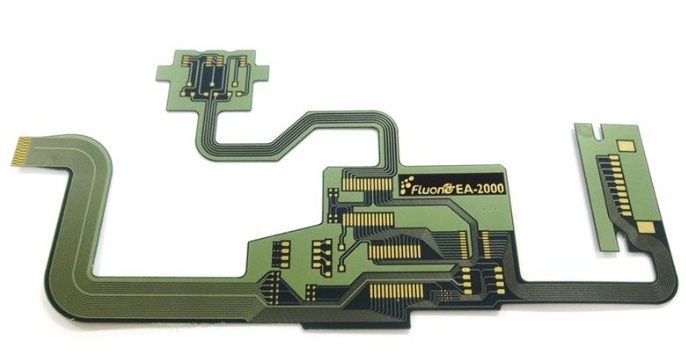

5G high-speed high-frequency printed circuit board produced using EA-2000

5G high-speed high-frequency printed circuit board produced using EA-2000

Source: Content based on“Nikkei Electronics”Aug. 2017, edited by AGC

Source: Content based on“Nikkei Electronics”Aug. 2017, edited by AGC

Furthermore, the remarkably low transmission losses of EA-2000 can be applied in both flexible and rigid CCL, allowing it to be employed in a wide variety of printed circuit boards including those for smartphones and other mobile devices, base stations, servers, and automotive equipment. The decision for the drastic expansion of the EA-2000 production facility has been made in response to the expectations of a significant increase in demand which are to accompany the upcoming practical implementation of 5G.

In the AGC Group’s long-term management strategy “Vision 2025,” AGC has designated its mobility and electronics businesses as strategic businesses, with 5G particularly considered to be a tremendous business opportunity in those areas. From here on, AGC will continue to integrate and combine the technology in glass, electronics, chemicals and ceramics which have been cultivated over many years, to contribute to the growth of next-generation high-speed communications technology while actively expanding our businesses in these fields.

Notes

*1. 5G: 5th-generation mobile communication system. Its required characteristics are“high speed with large capacity,”“ultra-high reliability with low delay,” and “ultra-large connection capacity.”

*2. CCL: Abbreviation for “Copper Clad Laminate.”

*3. Transmission loss: Extent of degradation suffered by electrical signals as they travel over communication lines.

*1. 5G: 5th-generation mobile communication system. Its required characteristics are“high speed with large capacity,”“ultra-high reliability with low delay,” and “ultra-large connection capacity.”

*2. CCL: Abbreviation for “Copper Clad Laminate.”

*3. Transmission loss: Extent of degradation suffered by electrical signals as they travel over communication lines.

Reference Information

About the AGC Group

AGC Inc.(Headquarters: Tokyo, President & CEO: Takuya Shimamura) is the parent company of the AGC Group, a world-leading glass solution provider and supplier of flat, automotive and display glass, chemicals, ceramics and other high-tech materials and components. Based on more than a century of technical innovation, the AGC Group has developed a wide range of cutting-edge products. The AGC Group employs some 50,000 people worldwide and generates annual sales of approximately 1.5 trillion Japanese yen through business in about 30 countries. For more information, please visit www.agc.com/en

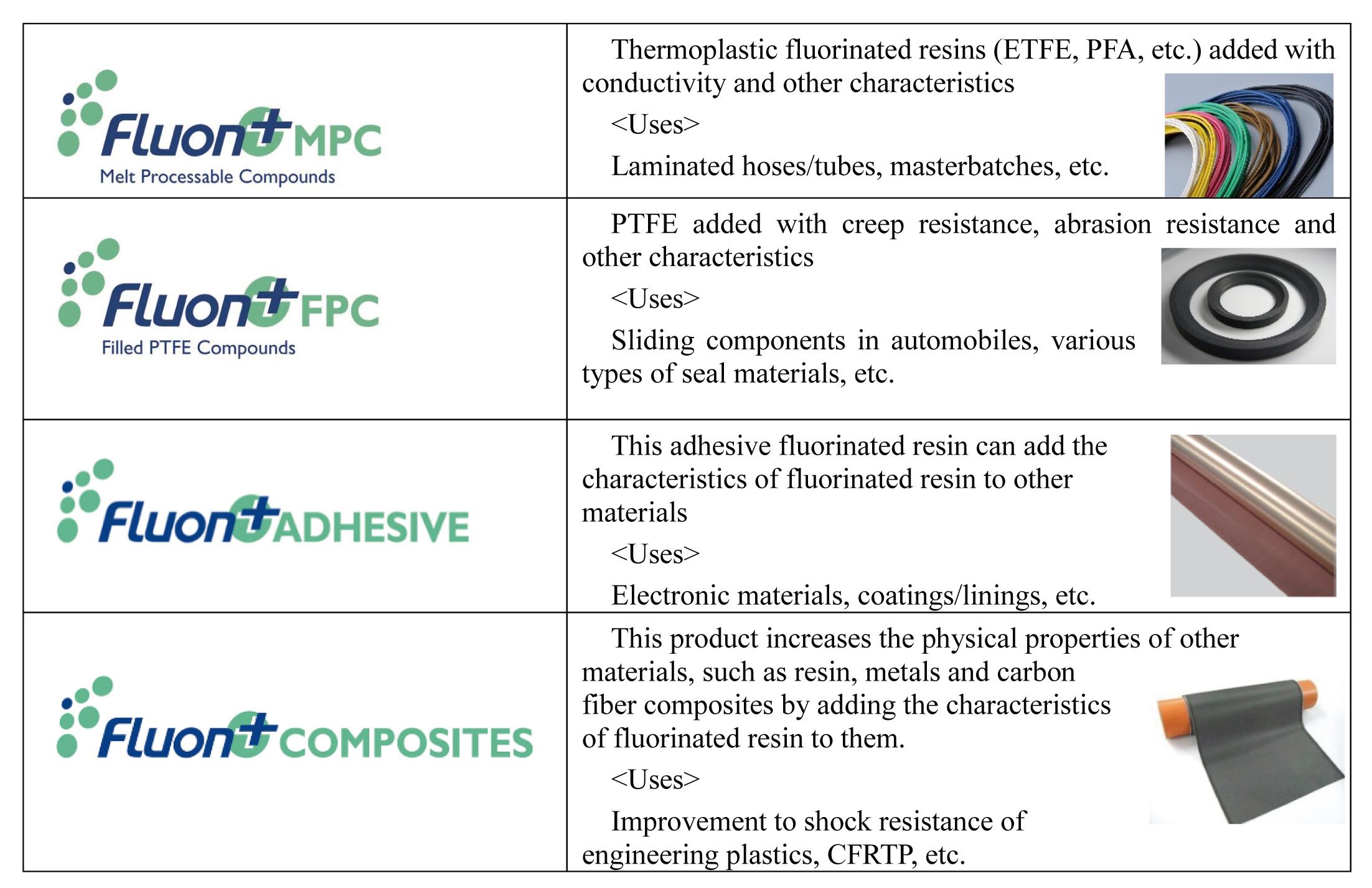

AGC’s Fluorinated resin Business

AGC’s fluorinated resin business includes a lineup of ETFE, PTFE, and PFA products under the Fluon® brand, which can fulfill widely-varying requirements in accordance with customers’ requested properties and processing conditions. On July 1, 2018, the new Fluon+ brand was launched with the concept of “giving fluorine additional value and functionality.” EA-2000 is one product in the Fluon+ ADHESIVE group, and it can be used as a material for coatings and linings or as a composite material, in addition to its application as a printed circuit board material. The Fluon+ brand lineup is as shown below.

AGC Inc.(Headquarters: Tokyo, President & CEO: Takuya Shimamura) is the parent company of the AGC Group, a world-leading glass solution provider and supplier of flat, automotive and display glass, chemicals, ceramics and other high-tech materials and components. Based on more than a century of technical innovation, the AGC Group has developed a wide range of cutting-edge products. The AGC Group employs some 50,000 people worldwide and generates annual sales of approximately 1.5 trillion Japanese yen through business in about 30 countries. For more information, please visit www.agc.com/en

AGC’s Fluorinated resin Business

AGC’s fluorinated resin business includes a lineup of ETFE, PTFE, and PFA products under the Fluon® brand, which can fulfill widely-varying requirements in accordance with customers’ requested properties and processing conditions. On July 1, 2018, the new Fluon+ brand was launched with the concept of “giving fluorine additional value and functionality.” EA-2000 is one product in the Fluon+ ADHESIVE group, and it can be used as a material for coatings and linings or as a composite material, in addition to its application as a printed circuit board material. The Fluon+ brand lineup is as shown below.

- Media inquiries

- Kazumi Tamaki, General Manager, Corporate Communications & Investor Relations Division

AGC Inc. - Contact: Yuki Kitano

- TEL: +81-3-3218-5603

- E-mail: info-pr@agc.com