November 13, 2018ProductsOthers

AGC Develops 'CARBOGLASS™ LF', a Polycarbonate Sheet Able to Resist UV Degradation and Self-Heal

Includes Lumiflon® coating, an ultra-weather-resistant fluoropolymer resin

AGC (Headquarters: Tokyo; President: Takuya Shimamura) has developed CARBOGLASS™ LF a polycarbonate sheet with remarkable weather-resisting and self-healing properties. Mass production of the product is scheduled to begin in 2019 with sales aimed at noise barriers, fences and other various outdoor installations.

Due to its excellent transparency and durability, polycarbonate is used in several applications such as protective fences and highway noise barriers. However, it also has a drawback, namely that exposure to ultraviolet (UV) rays causes it to degrade (i.e. brittleness, fading). Weatherproof-grade products that incorporate a protective layer of UV absorbing compound on the surface are also sold, but these products deteriorate after long-term exposure to UV rays, eventually degrading to a point where UV rays reach the polycarbonate.

| ・ | UV absorbing compound remains intact even after long-term exposure to UV rays, thereby maintaining the product's durability and transparency over the long-term |

| ・ | Provides self-healing properties that repair small scratches as time passes |

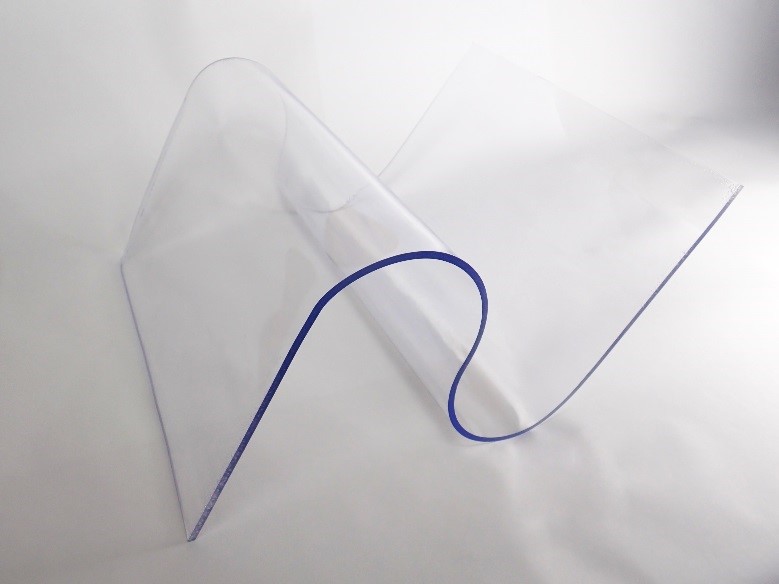

| ・ | Does not develop surface cracks even when heat-bent, opening up more possibilities for design shapes |

Heat-bent CARBOGLASS(TM) LF

Heat-bent CARBOGLASS(TM) LF

■ More details at: http://www.filmtech.jp/en/

― Notes ―

1: An ultra-weather-resistant fluoropolymer resin for coatings. Developed by AGC, this product protects coated objects from outdoor environments, thereby helping to improve their durability. Since its launch in 1982, it has been used on architectural structures around the world.

― REFERENCE―

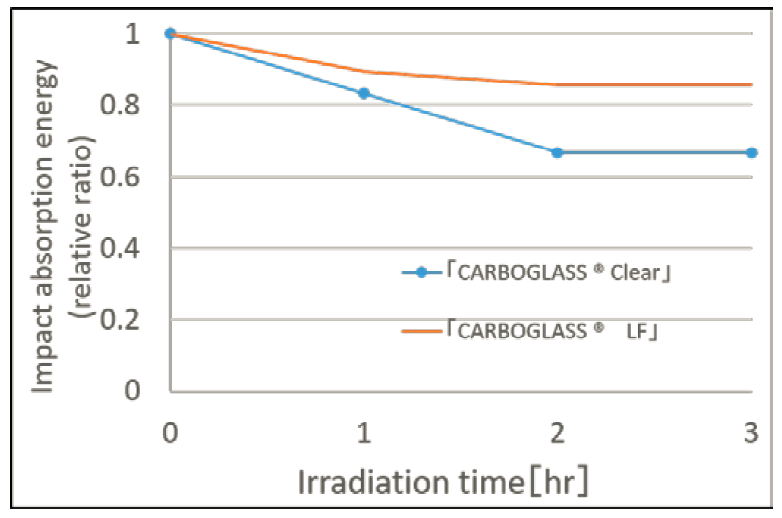

Comparing the changes in impact resistance in products subjected to 3-hours of high-power mercury lamp exposure (UV rays) found that the impact resistance of a sheet of polycarbonate (CARBOGLASS™ Clear) or co-extruded product fell 30% lower than before exposure, while a sheet of CARBOGLASS™ LF under the same conditions fell by only about 10%.

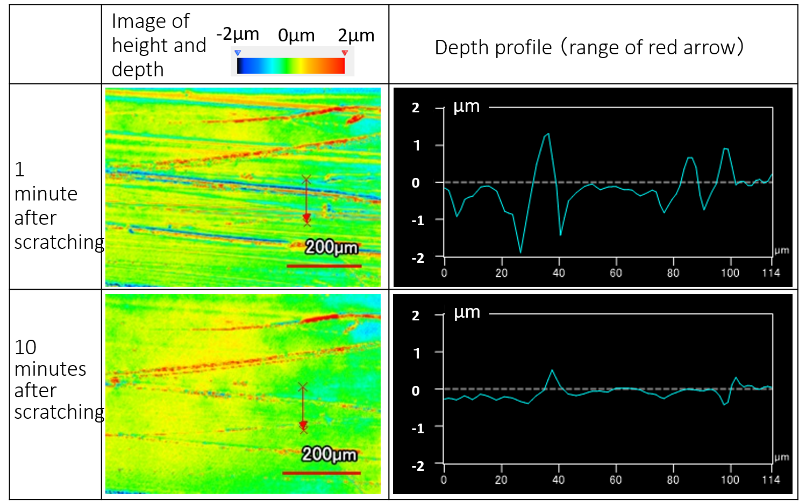

■ Self-healing properties (Fig. 2)

After being scratched by steel wool, the surface of the polycarbonate, if left at room temperature, gradually smooths out.

Figure 1 - Changes in Durability (Shock Absorbing Energy) from Ultraviolet Ray Exposure

Figure 1 - Changes in Durability (Shock Absorbing Energy) from Ultraviolet Ray Exposure

Figure 2 - Comparison of Scratch Healing Levels when Left at Room Temperature (1 min/10 min)

Figure 2 - Comparison of Scratch Healing Levels when Left at Room Temperature (1 min/10 min)

- MEDIA INQUIRIES

- Kazumi Tamaki, General Manager, Corporate Communications & Investor Relations Division

AGC Inc. - Contact: Ai Ota

- TEL: +81-3-3218-5603

- E-mail: info-pr@agc.com