A Message from the Chief Technology Officer

AGC will step up the pace of R&D by focusing on ambidextrous development, open innovation, and digital transformation.

Representative Director, Executive Vice President, CTO,

General Manager of the Technology General Division

Accelerating Development to Meet Changing Needs

Over the more than 100 years since its founding, the AGC Group has refined core technologies in the fields of materials, functional design, and production. At the same time, we have accumulated and evolved common basic technologies, such as analysis, evaluation, and simulation technologies, and combined them with our core technologies. These combinations have formed the basis of high-value-added solutions that could not have been achieved through the application of technologies in isolation. In this way, we have helped address social issues in each era.

Social issues are currently becoming increasingly complex, and our customers are seeking a greater variety of advanced solutions in response. In addition, with the faster pace of social change, the timely creation of solutions is gaining importance. The AGC Group will reflect such changes and continue helping solve social issues by increasing the speed of development through an emphasis on ambidextrous development, open innovation, and digital transformation.

Ambidextrous Development

-Heightening the Competitiveness of Existing Businesses While Creating Tomorrow

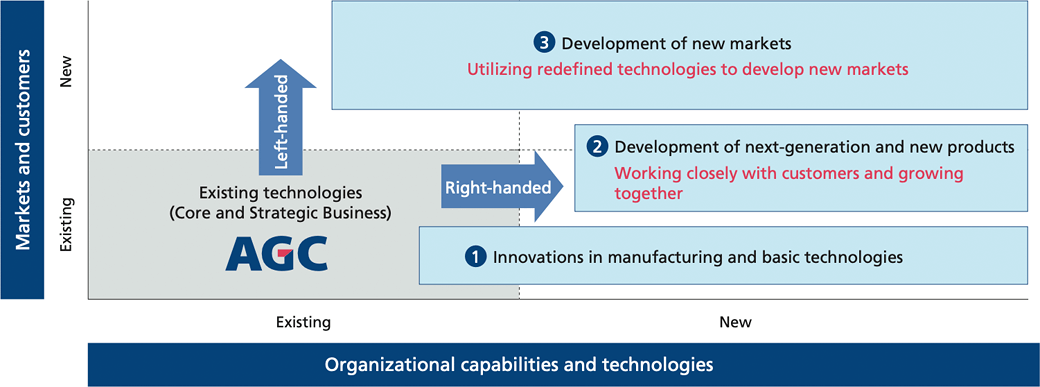

First of all, let me explain ambidextrous development. “Right-handed” development refers to the innovation of existing production technologies and basic technologies and to the development of new products together with our customers. Involving working closely with customers and catering to their needs, this type of development uses a forecasting approach in which current conditions are the starting point of projections and improvement measures.

“Left-handed” development, by contrast, is based on backcasting, which begins by anticipating future trends and then undertakes the initiatives and new business creation needed to adapt to these trends. In other words, the goal of left-handed development is to open up new markets by redefining existing production technologies and fundamental technologies.

Both types of development are important. The AGC Group has grown and evolved by heightening the competitiveness of existing businesses through right-handed development while helping create the future through left-handed development. A balanced approach combining both types of development is essential to ambidextrous development. My role is to consider how our finite management resources should be allocated to right-handed and left-handed development. By remaining aware of the overall situation, I try to maintain an optimal balance in the allocation of our management resources.

Open Innovation

- Promoting Collaboration with External Partners

Next, I would like to focus on our approach to open innovation. As I mentioned earlier, modern society is calling for faster responses to issues that are becoming ever-more complex. Given the growing difficulty of addressing such social issues using only the AGC Group’s proprietary technologies or combinations thereof, collaboration with customers, universities, research institutions, startup companies, and other outside partners is vital.

The Group has conducted many different types of collaboration. A recent example is our joint development initiative with NTT DOCOMO, INC., a major telecommunications carrier. At present, finding locations in cities where mobile communication antennas can be installed is becoming difficult. In response, we have been partnering with the telecommunications carrier to develop WAVEATTOCH™, a glass antenna that can be installed from the interior side of existing window glass, thereby converting the windows of downtown buildings into antennas.

We are also advancing open innovation through industry–academia tie-ups, which include joint research with the University of Tokyo, Tokyo Institute of Technology, and Nagoya University. Moreover, industry–academia tie-ups not only augment the skill sets of our research personnel but also provide university students with opportunities to gain knowledge and experience. Thus, such projects are very meaningful in terms of enhancing the R&D capabilities of Japan as a whole.

In addition to the aforementioned efforts with external partners, the Group aims to accelerate innovation by promoting collaboration among in-house businesses. To this end, we established a collaborative creation space, AGC Open Square (AO, pronounced “ah-oh”), on the premises of the AGC Yokohama Technical Center (YTC) in 2020. YTC has thus established a platform for collaborative creation based on the concepts of “connect,” “create,” and “materialize”. During the COVID-19 pandemic, we have continued to collaborate with supporting companies, universities, and other outside partners, while taking particular care to prevent the spread of infections among the many people who visit the facility.

Also, by bringing together R&D functions that were previously split between two bases, YTC has created a system that seamlessly connects everything from materials and process development to equipment technology development. This integrated system gives in-house researchers more opportunities to interact with each other. We have high hopes for YTC as a hub for innovation.

Digital Transformation

-Shortening Development Lead Times by Utilizing New Digital Technologies and Methods

The third factor is digital transformation, or DX. For example, by applying materials informatics—which means the use of AI, big data analysis, and data mining in materials development and composition development—the AGC Group is increasing the competitiveness and speed of its R&D.

An example of a product that originated from the application of materials informatics is AMOLEA™, an environment-friendly fluorinated solvent. Normally, when developing fluorine compounds, many candidate compounds have to be actually synthesized. In developing AMOLEA™, however, before conducting actual synthesis we narrowed down candidate compounds by running AI-enabled simulations that referred to a database comprising our accumulated data and data collected from published papers from around the world. This approach has helped to improve the efficiency of development.

Also, we are dramatically truncating development lead times through the use of virtual reality for prototype creation and tests that formerly had to be carried out in the real world. Such initiatives include utilizing virtual reality spaces to share visual representations of architectural or automotive glass installations with customers. Also, we are using numerical analysis methods to predict the fracture patterns of chemically tempered glass.

Developing Personnel and Technologies to Continue Benefiting Society

In manufacturing, technologies are key. Accordingly, the continued creation of technologies that earn worldwide recognition is essential for the sustained growth of AGC’s corporate value. Given that only people can create technologies, the establishment of a culture that nurtures personnel and technologies and thereby enables the Group to continue contributing to society is paramount. We must always set challenging goals, a mindset encapsulated by the motto expressing our founding spirit: “Never take the easy way out, but confront difficulties.” Further, whatever lofty goals we set, I am confident that we have the ability to accomplish them.

I am committed to carefully analyzing the ambitious goals proposed by each person and to holding discussions with personnel to support the achievement of these goals. My own goal is to create workplaces where diversity is recognized, all kinds of opinions can be expressed, and personnel have an ongoing sense of optimism and personal growth. Accordingly, I will fulfill my responsibilities as chief technology officer with a view to realizing this goal and creating employee-friendly work environments of which personnel can be proud.