AGC delivers slurries and polishing solutions for CMP processes as the fully integrated manufacturer from abrasive production.

To realize multi-layered structures with high levels of flatness and zero defects, we optimize our slurries with high planarization and selectivity control technologies for not only silicon-based materials such as poly-Si, SiO2 and SiN, but also metals and resin that fulfill various technical requirements from CMP processes in semiconductor front-end, back-end, packaging and so on.

Applications

- CMP processes in semiconductor front-end, back-end, packaging and so on.

*Examples of polishing materials: Silicon-based materials (poly-Si, SiO2, SiN), metals, resin

Features

- Design and manufacturing of abrasive particles

- Accumulated technology of polishing materials for glasses

- Design and manufacturing of various analyses and chemical liquid

- Polishing material evaluation technology

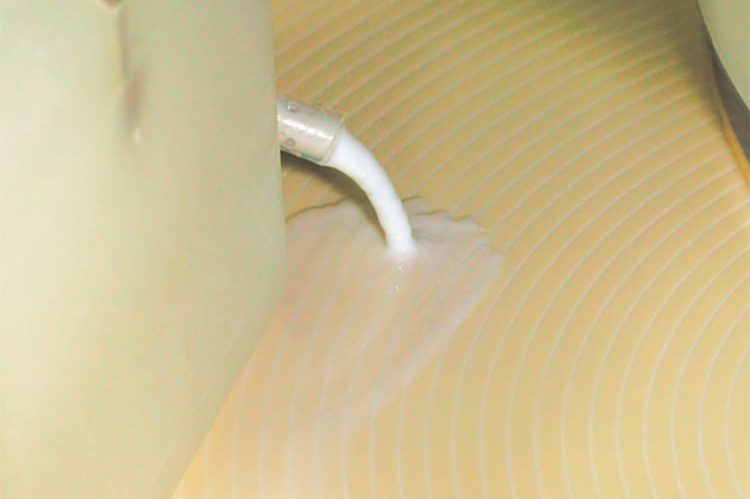

CMP Process

CMP Process

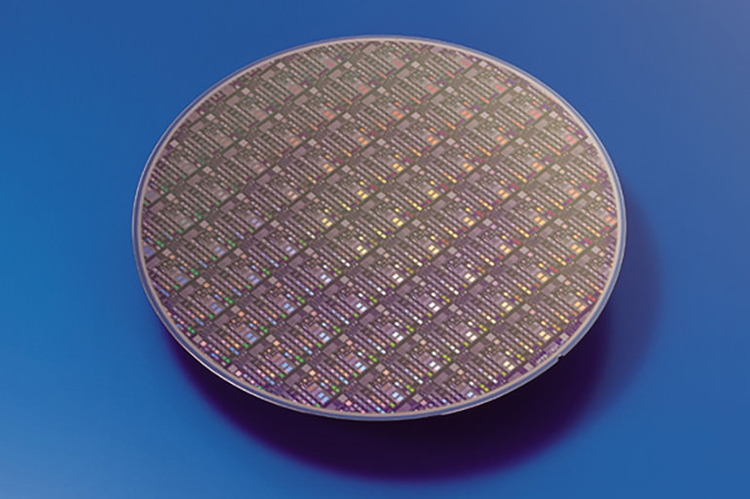

Polished 8-inch Wafer

Polished 8-inch Wafer

(A highly planarized multilayer structure can be achieved)

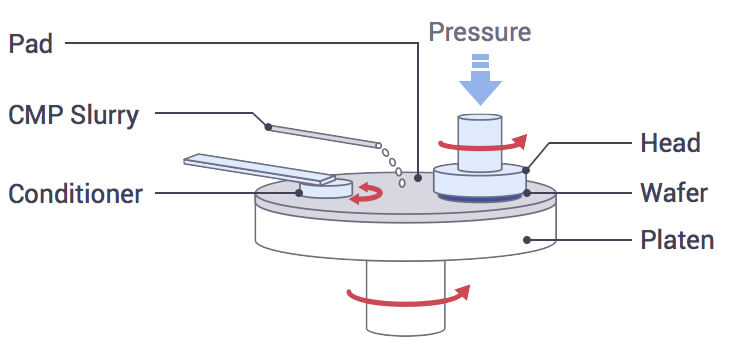

Chemical Mechanical Polishing

Chemical Mechanical Polishing, or CMP, has quickly become an indispensable technique for fabricating integrated circuits. During the CMP process, a wafer surface is polished for planarization using a slurry and a polishing pad. The abrasive particles in the slurry grind against the sample surface, loosening material. The chemicals in the slurry then etch and dissolve the material. This process is designed to remove areas of elevated topography more quickly than the lower areas. Although mechanical grinding alone can achieve a reasonable degree of planarization, chemical etching is necessary to remove the extensive damage from mechanical grinding. Although chemical etching results in a damage-free sample, the process is typically isotropic and does not remove topographical features.

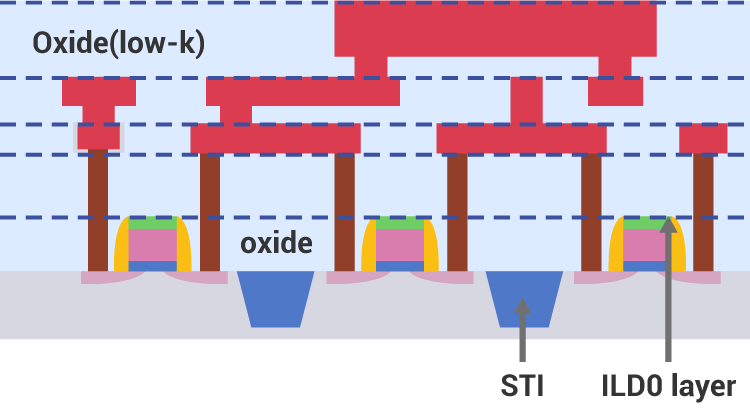

Ceria slurry for STI/ILD Applications

CES-300 Series/330F Series

・Slurry for STI Applications

・Slurry for ILD Applications

For the application of silica insulation film, we provide high-function ceria slurry which excels in step flattening property, material selectivity, uniformity, and has less frequency of defects, as a raw material solution including polishing conditions. Additionally, it is able to support a supply method of both one liquid and two liquids.