Common Basic Technologies

AGC's shared core technologies have been accumulated and deepened over many years. They include highly sophisticated materials technology, functional design technology that yields enhanced functionality through convergence with materials technology, and production technology that enables stable production of high-quality products. Through our efforts to meet customers' expectations and our experience of utilizing various materials, we have also accumulated technologies for designing parts by assembling various materials. We use these technologies to bring out the full potential of materials.

Analysis and Evaluation

In order to analyze and evaluate the physical properties and other characteristics of the materials that we use in our products and production processes, we need to develop and apply innovative analytical technologies and continually enhance existing technologies and methods. These technologies are becoming more and more important for a number of reasons. For example, the analysis and evaluation methods that we develop, which are unique in the world, lead to improvements in product quality and reliability and the creation of new products, resulting in customer satisfaction. AGC has established a solid technical foundation by developing, expanding and transferring essential analysis and evaluation methods. In recent years we have also focused on the development of cutting-edge technologies and skilled human resources for the future through collaborative development and the deepening of advanced technologies through open innovation.

Simulation

AGC first used simulation technology around 50 years ago to recreate glass flows in melting furnaces. Since then, we have used knowledge gained from process simulations to improve our product quality and productivity. In addition to these macro-level analyses, we are also working toward a better understanding of phenomena at the atomic level through the use of material simulations, which enable us to determine the best approach to designing compositions and structures. We are also responding to the growing demand for composites that combine dissimilar materials through collaboration activities with customers, starting at the early design stage. We achieve this by designing composite simulation functions based on the properties of individual materials and the structures of composite materials. In recent years, AGC has also employed cutting-edge technologies from a variety of fields, including materials informatics, quantum computing, cloud computing, optimization computing, data science, and digital twinning, to ensure reliable supplies of products with enhanced quality, performance, and functionality.

Data Science

AGC is working to maintain its position as an industry leader in digital transformation (DX) by developing smart factories through process digitalization, and by utilizing the latest digital technologies, including materials informatics, AI, IoT, big data analysis and AR/VR, to transform all of our business processes. We have also prioritized human resource development, including a data scientist training program through which people learn to solve specific business problems through data science. By enabling personnel with work-specific expertise in such areas as materials development, production, sales, and logistics to acquire advanced data analysis skills, we are developing multiskilled personnel who will enhance our competitiveness through DX and continue to contribute to the creation of new value for our customers and society.

Sensing

Sensing technologies enable AGC to acquire useful data from production processes automatically. We value insights that allow us to determine which data will be truly useful for quality and production processes. We develop basic technologies and equipment technologies that we can use to acquire knowledge relating to product development and production activities in our core and strategic business areas, including process phenomena and product properties and formats. A particular priority is the achievement of the level of quality needed for transparent, flat glass by developing sensing technologies that can be used in situations that are unsuitable for conventional measuring technologies, such as high-temperature environments. Work in this area results in the proposal of systems, including measuring equipment, algorithms, and software, based on optical and data processing technologies, to support process digitalization and quality assessment. Significant benefits have been achieved by implementing these systems in actual production operations and offering production process solutions based on analyses of the data obtained from the systems.

Plant Engineering

AGC has its own in-house engineering organization, which is responsible for all of its engineering operations, from the development and design of production systems (processes and equipment) incorporated into processes, to the planning, design, procurement, construction, and commissioning of mass-production plants for both core and strategic businesses. The equipment that we design for our own use is unique in the world. Because much of our equipment must be able to withstand prolonged use in harsh environments, we have developed and accumulated advanced technologies ranging from material selection and device design to maintenance methods. We will continue to deepen our engineering technology so that we can provide high-performance, high-quality products while meeting increasingly demanding quality and environmental requirements.

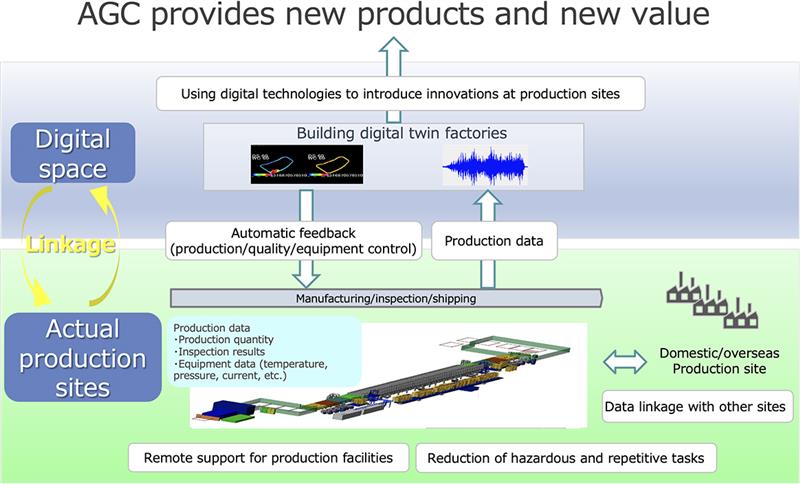

Smart Factory

AGC employs a variety of digital technologies to analyze and utilize data from production facilities as the basis for frontline production innovations. Examples of the benefits achieved include the following.

- Quality improvement through pre-assessment of production facilities based on simulations

- Ensuring reliable operations by analyzing data collected from production facilities to predict breakdowns

- The use of robotic technology to minimize hazardous and repetitive tasks traditionally carried out by human operators

- Provision of remote support for production equipment

By using these and other technologies, we can rapidly optimize production conditions by using digital data to provide central control and visualization of frontline manufacturing operations, and by sharing case studies about successes and failures in each plant in real time. The introduction of these innovations at production facilities has enabled AGC to enhance its competitiveness by rapidly bringing new products to the mass-production stage, and by supplying high-quality, low-cost products. AGC will continue to move forward with the evolution of its smart factories with the aim of contributing to the solution of issues facing modern society, including the effects of a declining birthrate, and the need to diversify workstyles and ensure that skills are transferred to future generations.