Our Story

This is the story of AGC’s growth and evolution as a supplier of materials to support industrial and social development since its establishment as Japan’s first manufacturers of sheet glass.

● The history of our corporate management

■ The history of our products and technologies

From 1907 to the 1950s

|

1907 ●Asahi Glass Co., Ltd. was established in Amagasaki, Hyogo Prefecture |

|

|

1909 ■Belgian hand-blown sheet glass manufacture begins. (The first of such production in Japan) |

|

|

1914 ●The first shipment of sheet glass was exported to England |

|

|

1916 ■In-house production of soda ash, a key raw material for glass, begins. |

|

|

1917 ●Headquarters was moved to Tokyo |

1917 ■In-house production of soda ash, a key raw material for glass, begins. |

|

1925 ●Shoko Glass Co., Ltd. was established in China as Asahi Glass’ first business outside Japan |

|

|

1928 ■Production of tempered glass and laminated glass begins. |

|

|

1933 ●The Asahi Foundation for Chemical Industry Promotion (now the Asahi Glass Foundation) was established to commemorate our 25th anniversary |

1933 ■Caustic soda production using the ammonia method begins. |

|

1937 ●Stocks were listed on the Tokyo Stock Exchan |

|

|

1938 ■Production of tempered glass and laminated glass begins. |

|

|

1939 ■Production of refractory bricks begins at the Iho Plant. |

|

|

1952 ●Concluded agreement to export caustic soda electrolysis equipment to Indonesia |

|

|

1954 ■Production of double-glazing units PairGlass™ begins. |

|

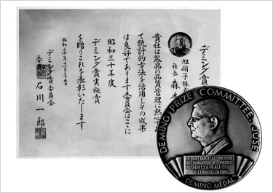

1955 ●Received Deming Prize for quickly adopting quality management |

1954 ■Manufacture of glass bulbs for television picture tubes begins. |

|

1956 ●Glass manufacturing subsidiary was established in India, demonstrating progress in expanding internationally ahead of other Japanese companies |

1956 ■Automotive glass business was launched on a full scale to respond to rapidly growing demand. |

|

1957 ●Asahi Glass Scholarship Foundation was established to Commemorate our 50th anniversary |

The 1960s and 1990s

|

1961 ■Production of propylene oxide and propylene glycol begins. |

|

|

1964 ●Entry into the flat glass market in Thailand |

|

|

1966 ■Production of float glass begins. |

|

|

1972 ●Commenced glass production operations in Indonesia |

1972 ■Product development of AsahiGuard™ water and oil repellents begins. |

|

1975 ■Development of the Flemion™ fluoropolymer ion-exchange membrane electrolysis method for manufacturing caustic soda. |

|

|

1980 ■AZEC System, a new ion-exchange membrane electrolyzer, was developed. |

|

|

1981 ●AGC Inc. acquired Glaverbel S.A. and MaasGlas B.V., glass companies in Belgium and the Netherlands |

|

|

1982 ■Production of fluoropolymer resin for coatings (LUMIFLON™) begins. |

|

1985 ●Full-scale entry of the automotive glass business in the United States |

|

|

1986 ●Full-scale entry of the chlor-alkali business in Indonesia |

|

|

1990 ■CYTOP™ transparent amorphous fluoropolymer was developed. |

|

|

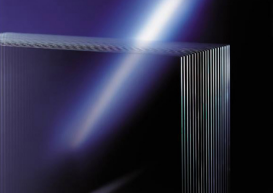

1995 ■Production of glass substrates for TFT-LCDs begins. |

|

|

1997 ●Entry into Russia’s glass market. |

2000s –

2002 ●Creation of AGC Group Vision, "Look Beyond" |

|

|

2005 ■Sales of automotive door glass that blocks infrared rays was launched. |

|

|

2007 ●The Group brand was unified as “AGC” |

|

|

2008 ■High-performance Fluon® ETFE FILM was used for various sports venues at global sports event in Beijing. |

|

|

2011 ■Worldwide sales of Dragontrail™ glass for smartphones and tablet computers begin. 2011 ■Sales of UV Verre Premium Cool on™ tempered glass for automotive door windows begin. |

|

|

2013 ●Started production of float glass in Brazil. 2013 ●Established regional headquarters in Singapore |

|

2016 ●Automotive glass production base established in Morocco 2016 ●Information gathering and marketing bases established in India and Dubai |

|

2017 ■AGC commences production of EUV mask blanks. |

|

|

2018 ●Bioscience businesses in Japan, U.S.A and Europe consolidated as AGC Biologics. |

|

2018 ●Change corporate name to AGC Inc. |

|

2021 ●AGC plus 2.0 management policy was implemented |