Ceramics

AGC offers a variety of products and solutions that contribute to innovation in glass production processes and environmental conservation.

Ceramics

AGC offers a variety of products and solutions that contribute to innovation in glass production processes and environmental conservation.

Products by industry

-

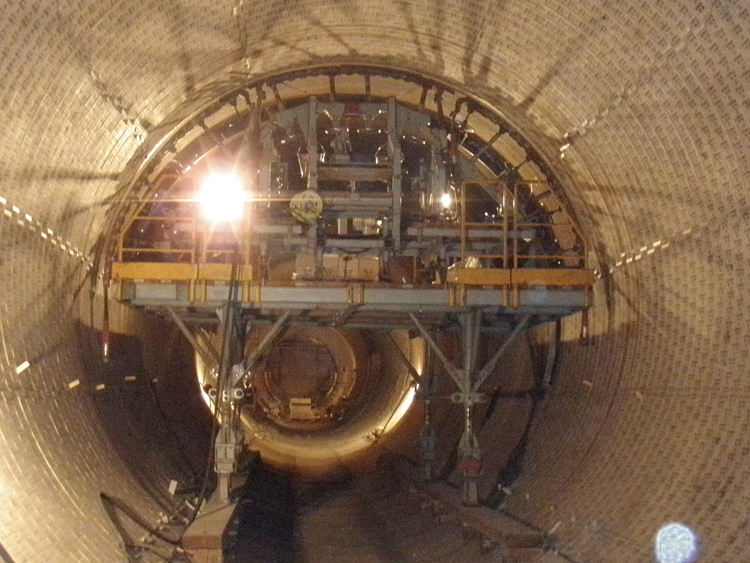

Refractories for Glass plants

Support the life cycle of glass furnaces

We optimally select and propose the materials for an “energy-saving” and “environmentally friendly” glass furnace, and offer support along every step of the life cycle.

Product Name

Refractories for Glass plants

-

Refractories for Cement plants

Refractory bricks with excellent high-flexibility against mechanical stress and thermal shock resistance

Technological innovations for environmental protection are progressing in the cement industry. We offer products and consulting services that respond to the environmental changes.

Product Name

Refractories for Cement plants

-

Refractories for Incinerator plants

The optimised refractory lining for your needs

We have a good product lineup of castable to satisfy the needs of each type of incinerators. We also make optimised lining that help to minimize an installation period and reduce the possibility of explosive-spalling during dryout by heating up.

Product Name

Refractories for Incinerator plants

-

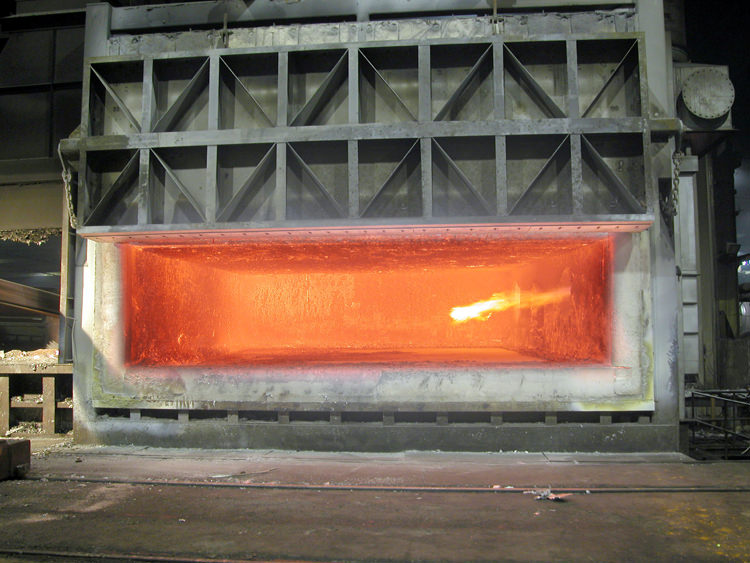

Refractories for Aluminum plants

High-durability and energy-saving

Based on our extensive experiences, we offer optimised refractory lining for aluminum melting furnaces and proposals to reduce radiation heat loss.

Product Name

Refractories for Aluminum plants

Solution products

-

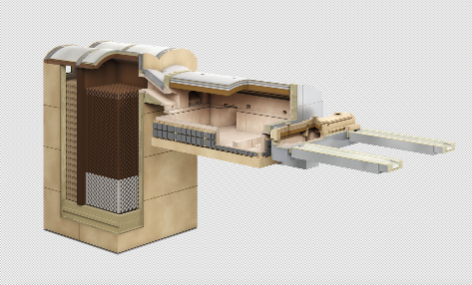

High Thermal Insulation Ceramics Wall for Furnaces

Energy-saving solution and environmental improvement for various industrial furnaces

High thermal insulation ceramics wall called “THERMOTECT WALL™” is a unique wall structure which has both high heat resistance and high thermal insulation in the furnace, and it contributes to energy-savings for each type of industrial furnace.

Product Name

THERMOTECT WALL™

-

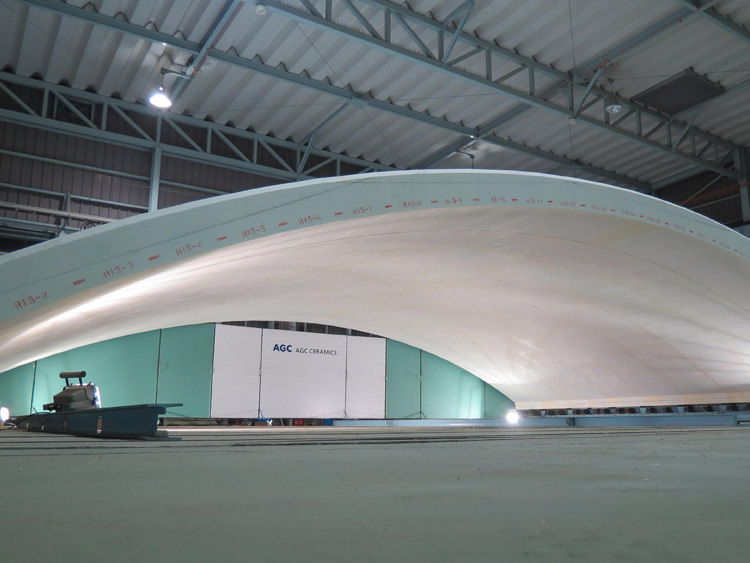

Glass Engineering

Glass Engineering

Comprehensive Support Technology for the Lifecycle of Glass Melting Furnaces

Product Name

Glass Engineering

Use

Glass melting furnace engineering

-

Fine Ceramics

Structural material with high strength and excellent heat, corrosion, and abrasion resistance

It has been adopted with high reliability for steel and non-steel applications, and will be offered for mobility and energy-related applications in the future.

Product Name

Fine Ceramics