Technology Development Strategy

Technology Development Strategies and Key Measures

The AGC Group will continuously generate innovations that will shape the next 50 or 100 years to realize a sustainable society. To achieve this goal, we will steadily implement four key measures: contributing to the acceleration of CX through ambidextrous development, enhancing competitiveness by accelerating DX, promoting sustainability management, and promoting open innovation, and aim to achieve results.

1.Contributing to the acceleration of corporate transformation (CX) through ambidextrous development

In the Technology General Division, through ambidextrous development that incorporates the concept of organizational ambidexterity into our technology strategy,

• We will advance the reliable launch of businesses and stable production through the deepening and expansion of basic technologies and production systems

• We will continue exploration of new strategic business areas by pursuing unique materials and solutions

• We will improve the quality and quantity of output through focused development activities.

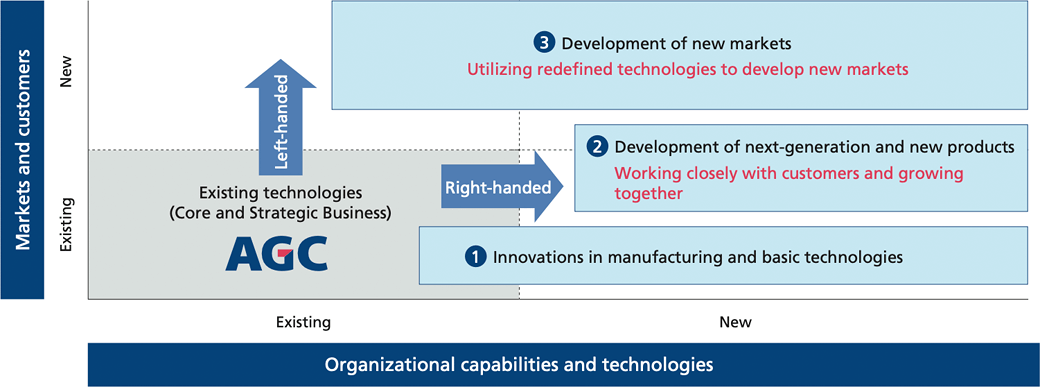

“Right-handed” development refers to (1) the innovation of existing production technologies and basic technologies, and (2) the development of next-generation and new products new products together with our customers. We aim to improve the essential competitiveness of our existing businesses through (1) and to evolve and expand our Core and Strategic Businesses through (2). ”Left-handed” development, by contrast, refers to (3) redefining existing capabilities (current production and basic technologies) and pioneering new markets. This is an approach that anticipates future major changes and creates new businesses and accelerates business portfolio shifts by creating new businesses in Strategic Business areas such as Mobility, Electronics, Life Science, and Performance Chemicals. To this end, the Technology General Division, in addition to deriving technology roadmaps from macro trends, identifies and organizes promising products and themes based on market potential, social issues, and suitability to AGC. This process defines the key areas of technology development and the focus target themes, which are regularly reviewed to advance development.

In development, we have replaced the traditional stage-gate method with the hypothesis-oriented planning method (DDP: Discovery-Driven Planning) to strengthen the management of the development theme portfolio and determine “what to discontinue, what to continue and strengthen, and what to start anew.”

2.Enhancing competitiveness by accelerating DX

Under the companywide strategy “Promotion of value creation DX” in the new medium-term management plan AGC plus-2026,

• the Technology General Division is proactively adopting advanced technologies related to DX, including generative AI. By leveraging data and digital technologies, we are pursuing the transformation of everything (products, operations, development processes, etc.).

• Through the promotion of DX, we will strengthen and expand our basic technologies, such as materials and process technologies, design and evaluation technologies, and production technologies.

• To reinforce our manufacturing and business platform, we will promote stable production and quality improvement, enhance maintenance capabilities, and further improve our safety, environment, and quality systems, which are key to our business competitiveness.

• We will promote an aggressive intellectual property strategy and standardization strategy to support our business.

Development of proprietary MI database and analysis tools

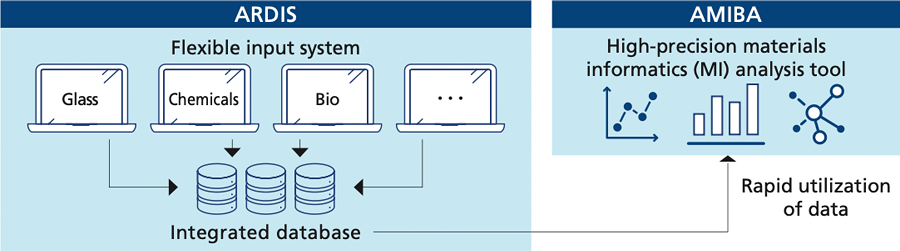

There is intense interest in materials informatics (MI), which can dramatically improve the efficiency of materials development through the application of computational and data science to the development of new materials and compositions. AGC was one of the first manufacturers to introduce MI, which it has used to develop new types of glass, the environment-friendly fluorinated solvent AMOLEA®, and various other products. However, it has been difficult to make extensive use of MI in wide-ranging fields because of various issues, including the lack of standardized storage formats for experimental data. AGC addressed the need for an integrated experimental data storage platform, which we saw as essential infrastructure for the use of MI, by developing MI database systems, including the AGC R&D Data Input & Storage (ARDIS) system, which incorporates an electronic laboratory notebook function for use in development activities, and the AGC Materials Informatics Basis Analysis Tool (AMIBA). This work is steadily opening the way for the development of materials by linking MI with experiments and theoretical computation through the use of software developed in-house to support computational science, including quantum calculations and molecular simulations.

AGC is creating the basis for an integrated development environment encompassing all stages from data entry to data analysis in order to support development activities in fields ranging from glass and chemicals to biotechnology. This environment is enhancing our understanding of phenomena and properties at all development stages, which promises to increase the efficiency of our R&D activities.

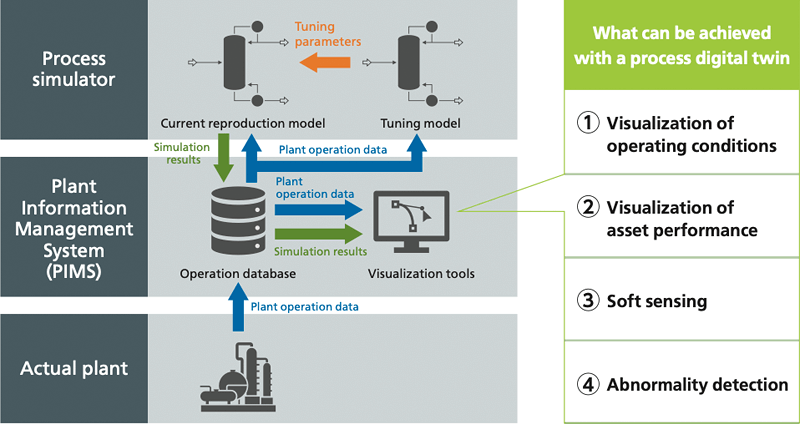

We developed a process digital twin for chemical plants and commenced its operation at a VCM (vinyl chloride monomer) manufacturing plant in Indonesia

A process digital twin is a technology that reproduces the current state of a plant in a virtual space by importing operation data of an actual plant into a process simulator in real time via Plant Information Management System (PIMS) and instantly performing high-speed calculations. By utilizing this system, data that could not be obtained or referred in real time can be estimated in the simulator to visualize operating conditions and asset performance. It is also expected to contribute significantly to stable plant operations by enabling instantaneous situational awareness and data-based decision making.

Process digital twin configuration

3.Promoting sustainability management

Under the companywide strategy for promoting sustainability management,

• the Technology General Division aims to create a dynamic organization that continuously generates innovation. We are committed to ensuring the implementation of DE&I and promoting smart work.

• We support individual growth and provide opportunities for success. Speci_cally, we are promoting the utilization of the 10% challenge quota and opportunities for training and growth as engineers, such as participating in academic activities.

• In the development of sustainability-related technologies, we are strengthening the development of GHG/environmental response technologies and deepening our efforts in energy-saving and recycling technologies.

Example of sustainability management: Success in Demonstration Test of Glass Production Using Hydrogen as Fuel

We have succeeded in a demonstration test of glass production using hydrogen as fuel at the electronics float glass manufacturing facility of the Kansai Plant, Takasago Factory (Takasago City, Hyogo Prefecture). This is the first time the AGC Group has conducted tests using hydrogen in an actual production furnace.

This test was conducted with the support of Air Liquide Japan G.K. (Chairman and CEO: Ilyong Park, Headquarters: Minato-ku, Tokyo) by implementing its hydrogen combustion burner to an existing conventional combustion process with oxygen using natural gas as fuel. We verified technical issues such as glass quality, the impact on furnace materials, flame temperature, furnace temperature, and nitrogen oxide (NOx) emissions. The results showed that we were able to maintain the appropriate temperature in the glass melting furnace while keeping the NOx concentration in the exhaust gas at the same level as in 100% natural gas.

Aiming for full-scale deployment, we will conduct scaled-up tests of the combustion capacity and consider demonstration tests at the AGC Group's global sites to determine the scope of application of hydrogen combustion technology.

4.Promoting open innovation

In recent years, as social changes have accelerated and customer needs are also becoming more sophisticated and diverse, it has become dif¬ficult for AGC to solve certain issues alone, and this has made collaborative activities through open innovation with external partners increasingly important. AGC is promoting open innovation on two axes. One is to develop innovative technologies and technologies outside of AGC’s ¬elds of expertise through collaboration with universities, other academic institutions, and startups. The other is to develop new products through collaboration with leading companies that are our customers. To this end, AGC has established a space for collaboration called “AO (AGC Open Square)“ at AGC’s Yokohama Technical Center, and is using it to promote open innovation based on the concepts of “connect,” “create,” and “materialize.”