A Message from the Chief Technology Officer

We will continue to improve and innovate with a sense of urgency to create social value through Innovation & Operational Excellence.

Representative Director, Executive Vice President, CTO,

General Manager of the Technology General Division

AGC’s strengths and vision for technology development

Our strength is Innovation & Operational Excellence

AGCʼs strength is Innovation & Operational Excellence, which is also stated in Our Shared Values of our corporate philosophy,“Look Beyond” . Throughout our long history dating to 1907,we have continued our business by responding to changes in the times. Operational Excellence means delivering reliable,dependable products that meet customer expectations.

However, sustainable growth cannot be expected from practicing this alone. The reason we have been able to

continue in business for nearly 120 years is because we have anticipated the times and continued to spark innovation.

For example, AGCʼs business began with the manufacture of architectural glass. Applying this technology, it expanded into the manufacture of automotive glass and then televisionglass. Later, although the Company contended with market changes following the loss of demand for cathode ray tubes, it boldly took on the challenge of launching its business in time with the advent of liquid crystal displays. Other examples of AGCʼs evolution are its entry into the fine ceramics and electronic materials businesses from the manufacture of refractory bricks, and its development from self-sufficiency in soda ash, the raw material for flat glass, into the chemicals business, which produces fluorochemicals and other highperformance products. We are able to achieve Innovation & Operational Excellence by steadily and reliably manufacturing and improving our products while simultaneously creating new ones. That is what makes AGC unique.

Continuing to take actions looking out over the next 50 or 100 years

Our vision in terms of technological development is to build a structure and culture to provide functional materials and

components with a view to the 50 and 100 years from now. As an example, we are amid a rapidly progressing evolution and

transformation in the automotive world from the perspective of mobility. We are looking out on and conceptualizing the future

of next-generation mobility and continuing to develop new strategies. If we continue to come up with such ideas and

concepts and propose them, we will be relied upon by leading companies driving mobility and be the first to be approached.Our vision is to continue our business by proposing and providing materials that the world needs in each era.

As part of our initiatives to create this momentum, we are promoting activities called “Business Outlook” and “Technology

Outlook.” The Business Outlook is to anticipate trends, such as how the world will change and what industries will develop in

the future, whereas the Technology Outlook explores what technologies will be needed to support such industries.

Internally these outlooks are used to ensure strategic alignment among divisions and prioritize development themes and the

like. We share our roadmap with external partners (potential customers, academia, etc.) and discuss future directions while

reviewing the roadmap itself, which is used for setting priority areas for medium- to long-term R&D activities.

Technology Development Strategy

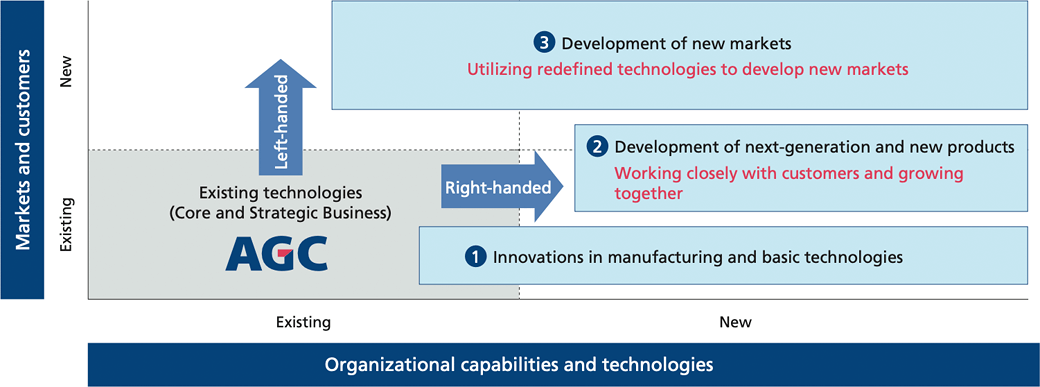

Ambidextrous Development

- Right-handed development: Innovating manufacturing and basic technologies to develop new products together with customers

- Left-handed development: Redefining proprietary technologies and developing new markets

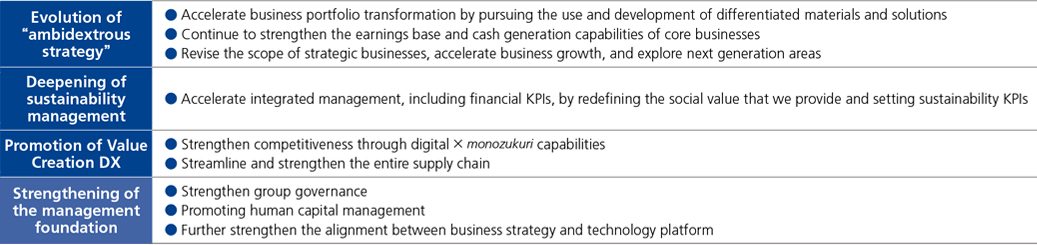

Progress and issues related to technology development in AGC plus-2026

Strengthening our footing through productivity improvement and innovation

In 2024, the first year of the AGC plus-2026 medium-term management plan (hereafter referred to as “the medium-term plan”), we recorded operating profit but a net loss.

One of the factors behind this was issues in terms of Operational Excellence. One example of this was the occurrence of production problems. The fact that it took time to get this back on track is a point that we need to reflect upon. With our business domains and supply chains expanding globally, we will focus on overcoming challenges at an early stage by leveraging AGCʼs strengths in organizational capabilities and production technologies more than ever before. Continuous innovation in productivity is also a priority for the future. As a manufacturer, improving productivity and innovation greatly contributes to improving our business performance. Under the banner of Operational Excellence, one of “Our Shared Values” in our Group Philosophy, we will further deepen collaboration between the manufacturing and R&D divisions and promote productivity improvement and innovation by making maximum use of digital technology. We will build a robust production process and strengthen the foundations of our business.

AGC plus-2026

Contribution to ROE improvement in the Technology General Division

A major priority in the medium-term plan is to improve ROE. We aim to raise ROE from its present low level to 7% during the period of the medium-term plan. To achieve this goal, the Technology General Division is developing high value-added products that will lead to higher ROE, and is also working on the selection of themes that have the potential to become Strategic Businesses in the future. In addition, we determine the prerequisites for the success of these themes as businesses, the time frame for their achievement and so forth, and formulate a roadmap (hypothesis) to reach the goal. Two years ago, we introduced “Discovery-Driven Planning (DDP),” a hypothesis-oriented planning method, and have been steadily advancing it by setting KPIs. In addition, we will utilize the experimental database system and data analysis tools developed by the Company to efficiently promote R&D while making full use of materials informatics (MI), which will lead to higher ROE.

Developing new technologies to reduce greenhouse gas emissions

AGC is committed to sustainability management that creates social value while generating economic value, and ensures the long-term continuity of its business activities. Among the several items listed as sustainability KPIs, the most urgent and significant issue that we can contribute to from a technological perspective is reducing greenhouse gas emissions. The manufacture of flat glass requires a large amount of energy in the combustion process of melting glass, resulting in high greenhouse gas emissions.

Therefore, we are continuously working to develop technologies to reduce greenhouse gas emissions. This is a major challenge for

the glass industry as well. We are currently conducting demonstration experiments in collaboration with Saint-Gobain, a leading French glass manufacturer, to develop technology that will significantly reduce CO2 emissions during flat glass manufacturing,thereby advancing decarbonization in the glass industry.

Furthermore, we are working toward decarbonization by combining our technologies and assets with those of other companies in areas such as carbon recycling, which involves not only reducing emissions but also recovering CO2 as a raw material

and upscaling it as a valuable material through chemical synthesis.

Conversely, reducing environmental impact and complying with environmental regulations also present business opportunities,

and we are developing products that contribute to reducing greenhouse gas emissions with that in mind.

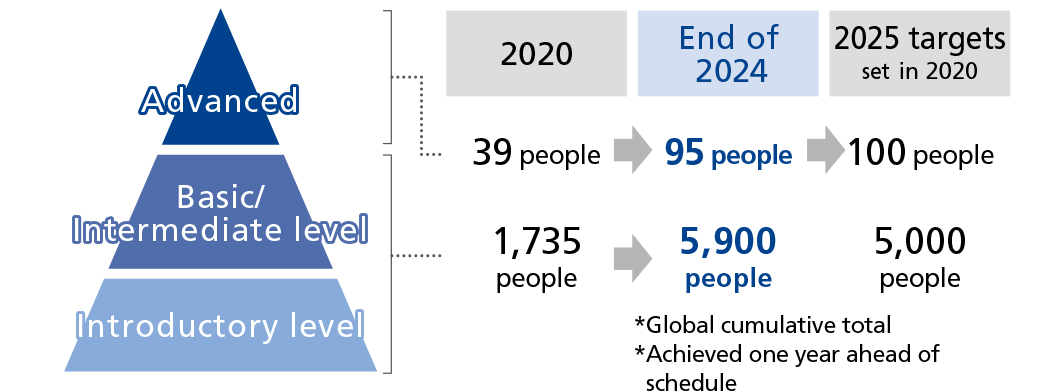

Innovation & Operational Excellence through value creation DX

We have been focusing on the fostering of DX-savvy talent since 2017, aiming to develop dual-skilled personnel. These are individuals with strong skills in both manufacturing and administrative operations, who proactively exploit DX to drive improvement and innovation. Currently, we have exceeded our goal of 5,000 people who have completed basic and intermediate level training in DX.

Also, we are close to achieving our target of raising 100 Top Data Scientists who can develop and deploy the latest digital technologies.

These professionals use DX to promote innovation at each workplace and accelerate the attainment of Innovation & Operational

Excellence. Value creation DX is producing many positive outcomes in a wide range of fields, including manufacturing, R&D, sales, and corporate functions as well as from being rolled out across the supply chain including customers and suppliers. The Digital & Innovation Promotion Division, newly established in 2023, is proving highly effective as a hub for leading productivity innovation and the internal deployment of the latest digital technologies.

Investment in human capital and placing the right people in the right roles

We are also focusing on human capital investment in our R&D division. We are systematically optimizing our human asset portfolio to place talented individuals with a variety of skills in the right roles. In addition, we are investing in the development of middle management to drive teams forward. We must break down organizational silos to harness the collective strength of the AGC Group to compete as a unified force. Toward that end, we also strive to increase the mobility of our talent and to increase opportunities for dialogue. The AGC Yokohama Technical Center, which serves as the hub for technological development, includes core technologies, materials technologies, process technologies, and production technologies in the same site. Furthermore, by bringing together a portion of the development divisions of all in-house companies, barriers between organizations and business divisions have been lowered to accelerate innovation through cross-functional collaboration.

Promotion of open innovation

The Center is also our hub for open innovation. The cocreation space “AO (AGC OPEN SQUARE),” which opened in 2020, hosted about 500 organizations and 3,000 visitors from client companies and academia in 2024. By building human networks outside the Group, we can expect not only immediate results in R&D and business, but also the emergence of innovative themes and ideas that will lead to social change and innovation 50 or 100 years from now.

Value creation strategies for technology development

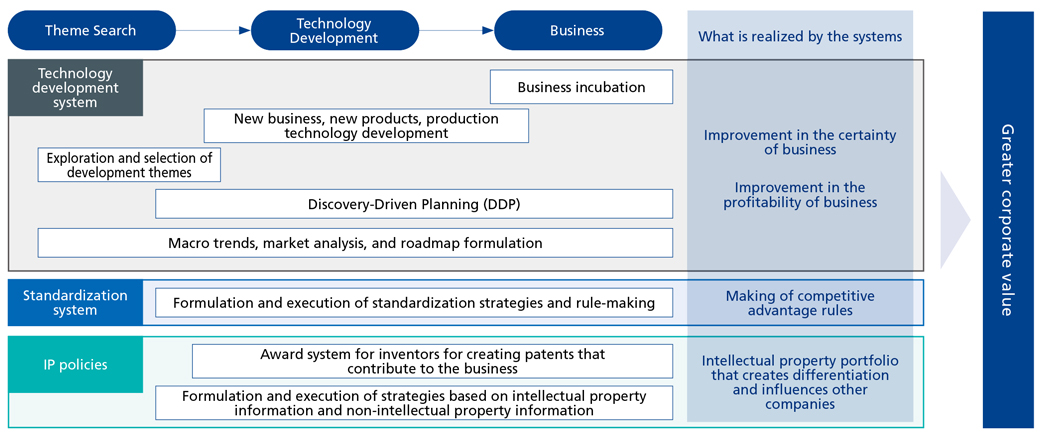

Improving R&D efficiency and increasing the probability of successful commercialization

The most important step in technology development is setting the issues and themes. Based on the analysis using the “Business Outlook” and “Technology Outlook,” AGC will determine the areas of focus for technology development and formulate a roadmap in line with the direction of AGCʼs “Business Portfolio Transformation” and “Vision.” In the search and selection of specific development themes, AGC will select themes that contribute to the social value of “Blue planet,” “Innovation,” and “Well-being” that AGC aims to create. Building on that foundation, one of the key missions or our research laboratories is to help shape the future by creating new business domains that will serve as pillars of the Company and by exploring the direction of portfolio transformation.

Proceeding with technological development of selected themes will be done using Discovery-Driven Planning (DDP) to constantly consider and decide on “what to discontinue, what to continue and strengthen, and what to start anew.” We incubate themes that are valuable from the perspectives of market potential, social issues, and AGCʼs strengths, thereby increasing the probability of successful commercialization and improving profitability. Making timely and accurate decisions on“what to discontinue or to continue” are essential for reducing unnecessary costs and effectively utilizing R&D personnel.

Aggressive approach to intellectual property initiatives

Traditionally, intellectual property has defended a companyʼs own business and technologies. However, patents on materialshave a high potential to be applied to various business fields as well as to be widely used in the world due to their properties.

As such, we are pivoting in our approach and actively linking our patents to profits. Therefore, we have changed the award system for inventors obtaining patents. The evaluation is no longer based on profits after commercialization but instead on an evaluation of the innovation and originality of the invention and its impact on competitors at the time the patent is registered. This allows R&D personnel to receive rewards at an early juncture, boosting their motivation. In fact, the number of people receiving awards is increasing.

Amid intensifying global competition, the more superior a productʼs performance is, the more challenging the competitive

environment becomes. To build an environment supporting competitive advantage under these circumstances, we are

formulating our intellectual property strategy with a strong awareness of our standardization strategy.

Continue to provide new value to the world based on the founding spirit of “Never take the easy way out, but confront difficulties.”

Since its founding, AGC has always been committed to providing new value to society, valuing the spirit of “Never take the easy way out, but confront difficulties.” The Company was founded in 1907 in response to growing demand for architectural glass during Japanʼs modernization. At the time, Japan did not possess the technology to mass-produce flat glass, making domestic production a challenge.

Nevertheless, with a firm sense of mission and resolve, the Company introduced overseas technologies and succeeded in achieving both domestic production and the widespread use of flat glass.

What is important in business is to always maintain a sense of urgency and a commitment to transformation and improvement, and

to continuously promote innovative initiatives. Toward this end, we endeavor to create an environment where each employee can feel a sense of personal growth and to lay the foundation for innovation.

AGC will continue to pursue innovation and strive to meet the expectations of all stakeholders. I myself share this sense of mission and will take action to achieve further growth.

Value Creation Strategy