January 30, 2024ManagementProducts

AGC to Build New Facility in Kitakyushu City for FORBLUE™ S-SERIES, Fluorinated Ion-Exchange Membrane Suitable for Green Hydrogen Production

- AGC is restarting its Chemicals Business in Kitakyushu City after 24 years -

Tokyo, January 30, 2024 - AGC (AGC Inc., Headquarters: Tokyo; President: Yoshinori Hirai), a world-leading manufacturer of glass, chemicals, and high-tech materials, has announced that it has decided to construct a new production facility for FORBLUE™ S-SERIES, a fluorinated ion-exchange membranes suitable for producing green hydrogen*1 at its Kitakyushu Site (Tobata-ku, Kitakyushu City) in Japan. AGC will invest approximately 15 billion Japanese yen for the new facility, which is scheduled to start operation in June 2026. After further capacity expansion, AGC aims to achieve FORBLUE™ S-SERIES sales of approximately 30 billion Japanese yen in fiscal 2030. This new plant will be AGC's third production site for its chemical business in Japan, following the Chiba and Kashima plants. The new operation will be a restart of AGC’s chemicals plant in Kitakyushu City after 24 years since the production of sodium bicarbonate was discontinued in 2002.

Green hydrogen, which is produced by water electrolysis process using renewable energy sources, is attracting attention as a next generation clean energy source, and many projects for its production and supply are being planned worldwide. The water electrolyzers currently in practical use today are mainly alkaline systems, which are suitable for power sources with stable load, such as hydroelectric power. Yet they are not suitable for power sources where the load fluctuates easily, such as solar power. Therefore, there are growing interests in the PEM*2 systems that can efficiently utilize these power sources. In addition, fluoropolymers are attracting attentions as materials that can achieve long-term durability of ion-exchange membranes used in the PEM systems.

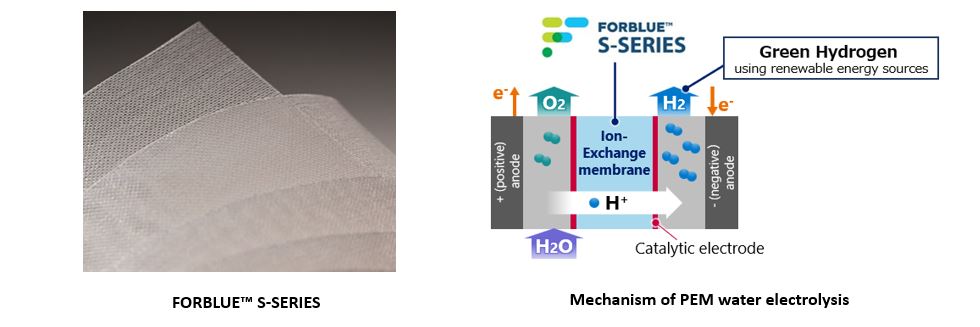

To address the rapidly growing global demand for green hydrogen, AGC has decided to build a new mass production facility for FORBLUE™ S-SERIES, a fluorinated ion-exchange membrane for PEM water electrolysis, which is made from its proprietary high-performance fluoropolymers. This series features the world-leading (1) voltage performance to suppress power consumption and (2) high gas barrier performance*3, which is important for operational safety of water electrolyzers. These characteristics are based on the polymer design and membrane formation technologies AGC has developed over many years. Pilot sales began in 2017, and the series has been highly evaluated by a wide range of customers since then.

Under its long-term management strategy Vision 2030, the AGC Group is aiming to contribute to the realization of a sustainable society through its unique materials and solutions. By providing the high-performance ion-exchange membranes suitable for green hydrogen production, AGC will contribute to the realization of a carbon neutral society.

Notes

*1 Hydrogen produced using renewable energy sources without emitting CO2 in the production process (Source: Agency for Natural Resources and Energy, Ministry of Economy, Trade and Industry website)

*2 Proton Exchange Membrane

*3 Refers to the difficulty in allowing gases to pass through (permeability). The better the gas barrier property, the more hydrogen and oxygen gases are prevented from mixing.

Reference

1. Overview of AGC's Kitakyushu Site

|

Location |

5-1-1 Makiyama, Tobata-ku, Kitakyushu City |

|

Business profile |

Logistics base functions and property management |

|

Number of employees |

8 (as of end-2023) |

|

History |

1914 Begins operations as a flat glass manufacturing plant |

2. FORBLUE™ family product lineup

The FORBLUE™ brand is a family brand of AGC product line that provide a "separation" solution for chemical substances.

|

FORBLUE™ FLEMION™ |

Ion-exchange membrane for salt electrolysis process (for producing caustic soda/caustic potash, and chlorine) |

|

FORBLUE™ SELEMION™ |

General purpose ion-exchange membrane and dialyzers (for purifying wastewater, etc., recovering and refining valuable materials) |

|

FORBLUE™ i-SERIES |

Electrolyte polymer dispersion for fuel cells |

|

FORBLUE™ S-SERIES |

Ion-exchange membrane for water electrolysis, redox flow batteries, a wide variety of electrolysis and electrodialysis processes |

|

FORBLUE™ sunsep™ |

Hollow fiber membrane gas dryer/humidifier |

- Media inquiries

- Chikako Ogawa, General Manager, Corporate Communications & Investor Relations Division

AGC Inc. - Contact: Nakao