April 1, 2025Environment & CSRR&D

AGC Develops Chemical Absorption Solution Significantly Enhancing CO2 Capture Efficiency from Air

—Demonstration to be Unveiled at Expo 2025 Osaka, Kansai—

AGC (AGC Inc., Headquarters: Tokyo; President: Yoshinori Hirai) a world-leading manufacturer of glass, chemicals and other high-tech materials, has developed a chemical absorption solution (hereafter referred to as “the absorption solution”) for Direct Air Capture (DAC) technology, which directly captures CO2 from the air. DAC is considered an essential technology for achieving carbon neutrality by 2050, and research towards its practical application is progressing worldwide. The absorption solution developed by AGC for DAC uses polypropylene glycol (PPG) as a non-aqueous chemical absorption solution, which significantly reduces energy consumption during CO2 capture compared to conventional aqueous chemical absorption solutions.

A demonstration experiment using the absorption solution to capture CO2 will be conducted at Expo 2025 Osaka, Kansai starting on April 13.

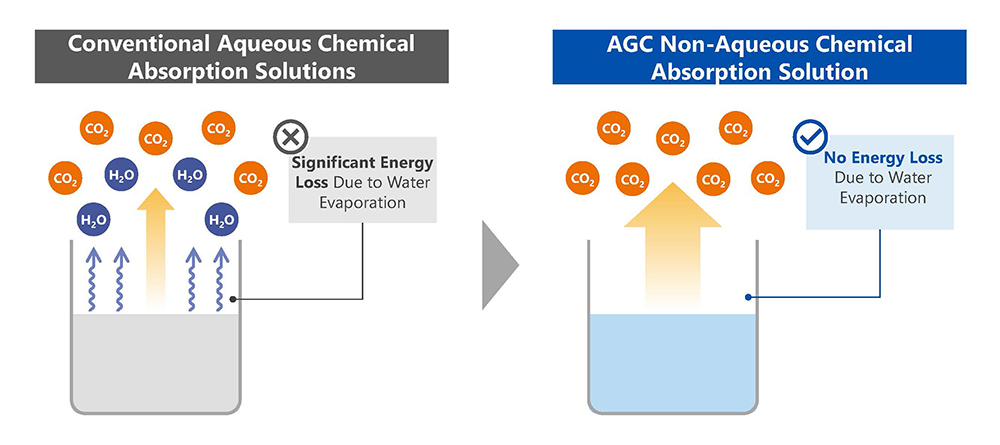

DAC is a technology that separates and captures the approximately 0.04% of CO2 present in the air using CO2 capture devices. Various methods are being researched for practical application. Among these, the method of using chemical absorption solutions to capture CO2 is notable for its ease of scaling up the equipment, making it promising for future use in large facilities such as factories. However, most chemical absorption solutions are mixtures of amines and water, which poses a challenge: when heat energy is applied to separate and capture CO2, the water evaporates, leading to excess energy consumption.

In response, we have developed a non-aqueous amine absorption solution that significantly reduces the energy consumption required for CO2 capture. The primary material of this absorption solution, polypropylene glycol is characterized by low volatility, resulting in minimal energy loss due to evaporation. Moreover, polypropylene glycol has high compatibility with amine compounds, allowing for stable separation and capture of CO2.

Additionally, our absorption solution is expected to be utilized in the “Cryo-DAC” *, which recycles the -160°C waste cold energy generated during the vaporization of liquefied natural gas to capture CO2. Since 2023, we have been conducting joint research with Nagoya University on the application of this absorption solution in Cryo-DAC. Moving forward, we will also participate as a subcontractor in the “Moonshot Research and Development Program” by the New Energy and Industrial Technology Development Organization (NEDO), in which Nagoya University is involved, to further advance research towards the practical application of our absorption solution.

Furthermore, we are exploring the application of our absorption solution to various CO2-containing gases, such as factory exhaust gases, in addition to Cryo-DAC.

In its medium-term management plan AGC plus-2026 , the AGC Group has defined “Deepening of Sustainability Management” as one of its key strategies and set a goal of achieving “Carbon Neutrality by 2050.” Going forward, the AGC Group will continue to contribute to the realization of a sustainable global environment through its unique materials and solutions.

About the AGC Group

AGC Inc.(Headquarters: Tokyo, President & CEO: Yoshinori Hirai) is the parent company of the AGC Group, a world-leading glass solution provider and supplier of flat, automotive and display glass, chemicals, ceramics and other high-tech materials and components. Based on more than a century of technical innovation, the AGC Group has developed a wide range of cutting-edge products. The AGC Group employs some 56,000 people worldwide and generates annual sales of approximately 1.7 trillion Japanese yen through business in about 30 countries. For more information, please visit www.agc.com/en

- Media inquiries

- AGC Inc.

Corporate Communications & Investor Relations Division