December 10, 2025ProductsEnvironment & CSR

AGC Completes World’s First UL2809 Third-Party Verification for Fluoropolymer PTFE Resin Using Recycled Fluorite

— Aiming for a Circular Economy for Fluorine Resources —

AGC (AGC Inc., Headquarters: Tokyo; President: Yoshinori Hirai) a world-leading manufacturer of glass, chemicals and other high-tech materials, announces that its Fluon® PTFE G grade*1 manufactured using recycled fluorite as the raw material, has completed third-party verification based on UL2809*2 this November. UL 2809 is a standard that defines the methods by which third parties verify self-declared percentages of recycled materials used by entities, based on ISO 14021. This is the first time*3 that UL 2809 verification has been completed for fluoropolymer PTFE resin worldwide. This grade, which is widely used in the semiconductor industry, is the first in the AGC product lineup to have the verification completed. AGC plans to expand the verification to other fluoropolymer products in the near future.

Initiative Toward Realizing a Circular Economy for Fluorine Resources

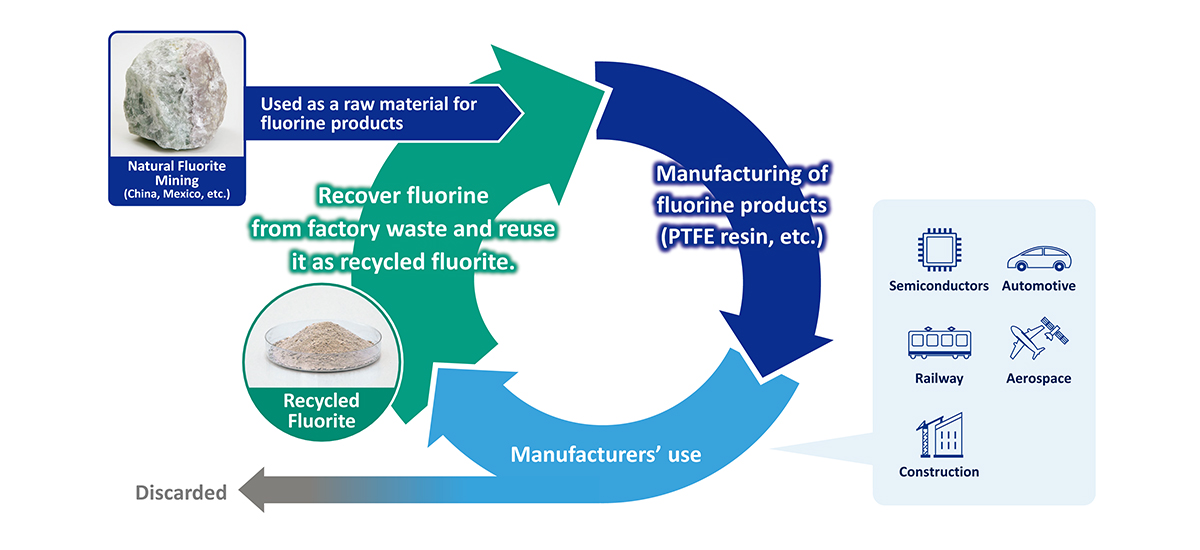

Fluorine products are essential for improving the performance, safety and durability of products in a variety of industries, including semiconductors and transportation equipment. However, as reserves of natural fluorite — the starting raw material — are limited, establishing a system for recycling and circulating fluorine is crucial.

Methods of circulating fluorine include recycling the same material, as well as recovering fluorine resources from waste and reusing them as recycled fluorite. Currently, however, most recycled fluorite does not meet the required quality standards for reuse in fluorine products. Most of it is used as a melting agent in steelmaking or as a secondary component for road base construction materials, where alternatives to fluorine resources already exist. The rest is discarded as waste. Consequently, the proportion of recycled fluorite that can effectively be reused as new fluorine products is very low.

AGC has successfully improved the quality of recycled fluorite recovered from waste using its own proprietary expertise and is now advancing its use in its own products. Moving forward, AGC will also advance initiatives to reuse recycled fluorite from waste at other manufacturers' plants in its fluorine products.

Under its medium-term management plan, AGC plus-2026 , the AGC Group has defined “Deepening of Sustainability Management” as one of its key strategies. The Group will continue to actively work toward realizing a circular society for fluorine resources.

Notes

|

*1 |

Also known as molding powder grade |

|

*2 |

UL 2809 (ECV: Environmental Claim Validation): This is a standard for verifying the recycled material content of a product. Products are evaluated according to the environmental performance verification procedure for recycled material content specified by UL Solutions, Inc. |

|

*3 |

According to AGC’s research |

Reference

|

■ |

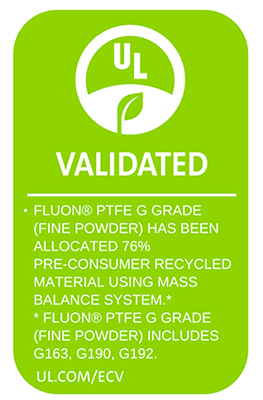

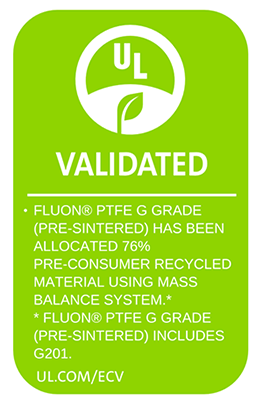

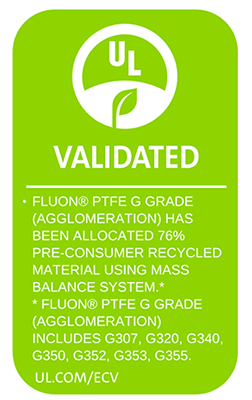

You can confirm this by searching "Fluon" on the UL Solutions website: UL-SPOT( https://spot.ul.com/ ). AGC has completed verification for the following three types of Fluon® PTFE G Grade fluoropolymer product. |

|

|

|

|

|

Fine Powder |

Pre-Sintered |

Agglomeration |

|

■ |

For additional information regarding our initiative toward realizing a circular economy for fluorine resources, please refer to our website. |

|

■ |

Product information of Fluon® PTFE G grade |

- Media inquiries

- AGC Inc.

Corporate Communications & Investor Relations Division