DOE and diffuser realized by high accuracy glass processing technologies

Applications

- Sensing

- AR/VR/MR

- Security

- Projector

- Optical communications

- Lighting

- Laser beam shaping

Diffractive optical element(DOE)

Features

- One-stop service from design, prototyping through evaluation

- Accumulated skills and experience on DOE processing

- Small 0th order transmission, high efficiency, high durability

- Capabilities of very large FOV and high density dot projection

- Multi-level steps processing

Diffractive optical element (DOE)

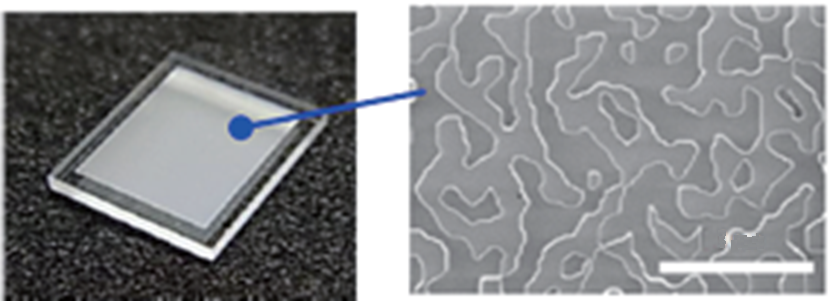

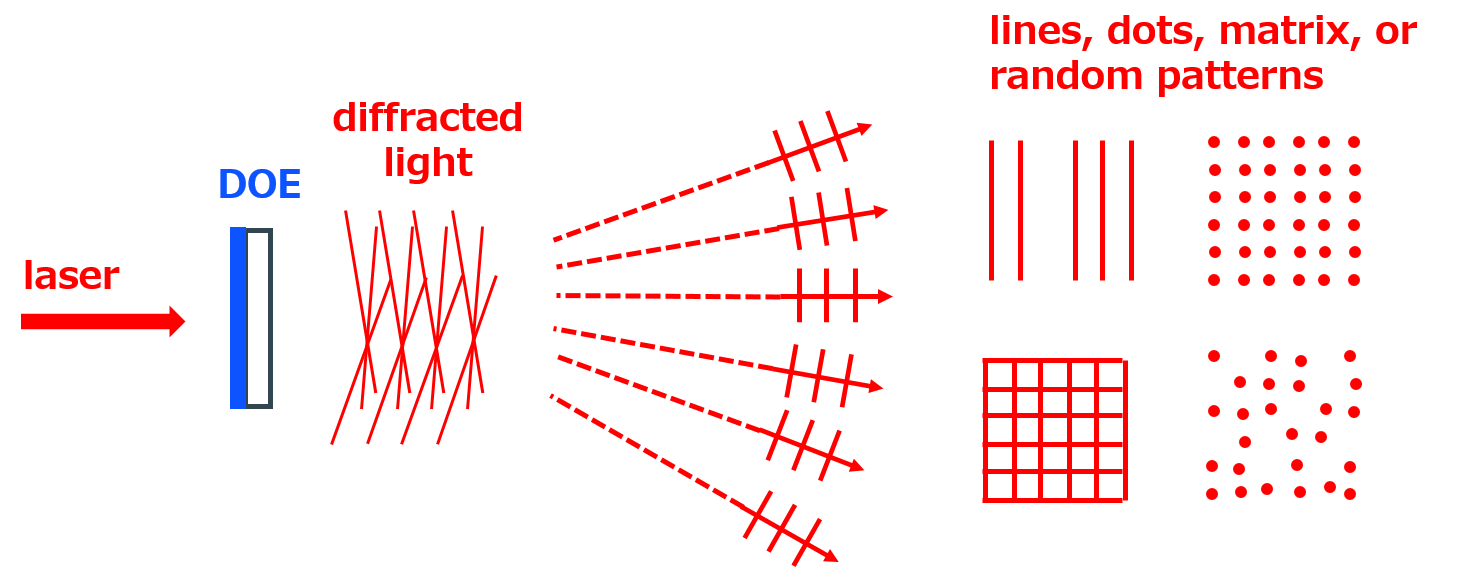

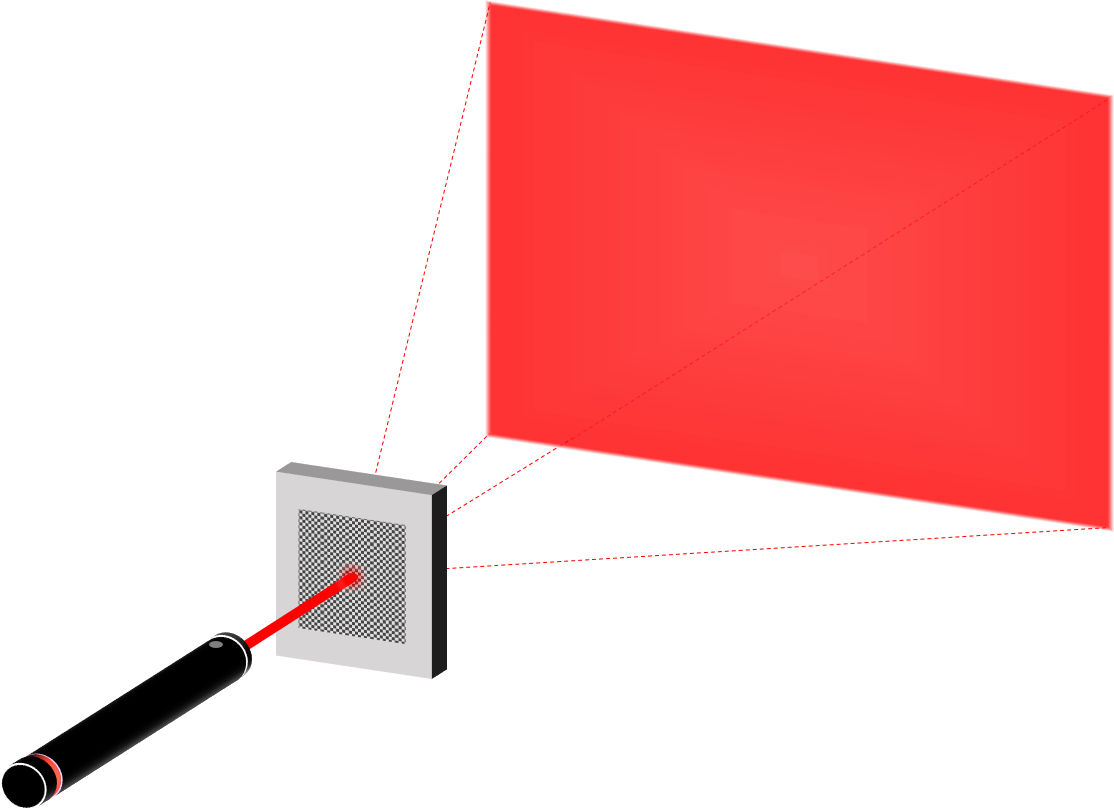

DOE has micro structured surface relief patterns which cause light diffraction. By engineering the diffraction, DOE can split, homogenize, and focus laser beams. A few examples of output beam patterns are illustrated below.

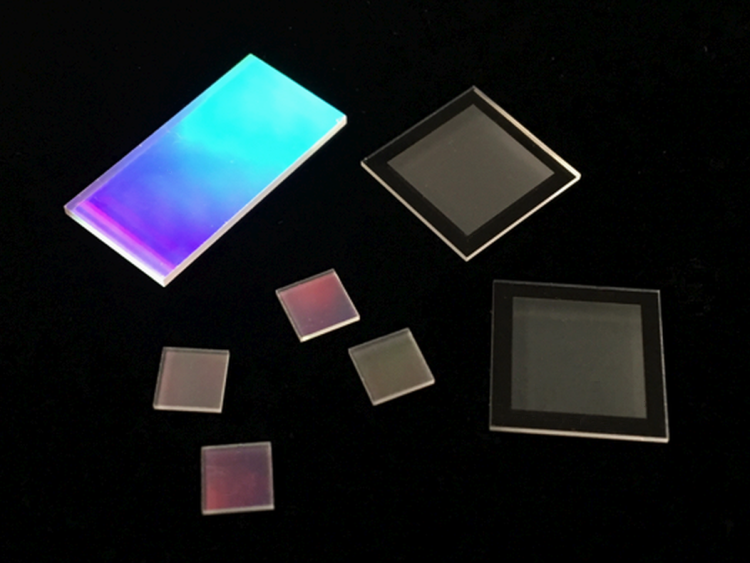

Appearance of DOE and its surface microstructure

Laser beam can be controlled using DOE

DOE design and fabrication by AGC

In AGC, we are developing and producing DOE using technologies cultivated though production of optical pickup and optical communication components. Our one-stop engineering service supports our customers from design through large volume mass production using originally developed simulation tools, materials, and rapid cycles of design and process optimization.

With accumulated skills and experience through our long-term technology development, our DOE enables low 0th order transmission, wide FOV, and large number dot projection. Using glass, our DOE also has high reliably against thermal, humidity, and laser damage.

Examples of DOE

A few examples of our DOE are shown here. For details or if you have any questions, please get in touch using the form at the bottom of the page.

Logo

~1k dot projection

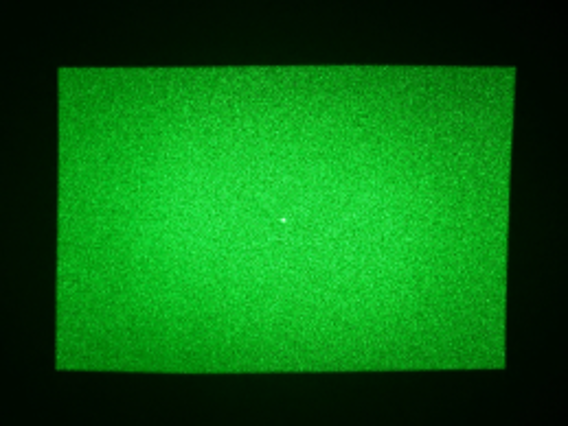

Uniform pattern projection

Glass diffuser

Features

- One-stop service from design, prototyping through evaluation

- Flat-top or 1/conn θ intensity profile

- Rectangular, circular beam shapes

- Tailoring X and Y diffusing angle, respectively

- Wide FOV

- High efficiency with little diffusion outside target area

- Custom design using originally developed know-hows

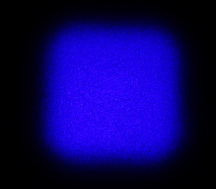

By micro-structuring glass surface, our diffuser tailors laser intensity profiles. While the far-field pattern becomes Gaussian when laser is input on typical diffusive material (e.g. frost glass), our diffuser can shape the laser circle or rectangle and control the intensity profiles (flat-top or 1/cosnθ). Our cut-off profile make little light diffuse outside the projected area, making it high efficiency.

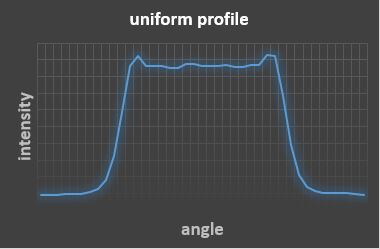

Uniform intensity profile using a diffuser

Frosted glass

Flat-top diffuser

Flat-top diffuser by AGC

Because our diffuser is using only inorganic materials, it has several advantages over polymer diffusers: easy to coat AR (anti-reflective) layer, high efficiency, high durability, and high laser induced damage threshold.

Like DOE, our one-stop engineering service supports our customers from design through large volume mass production using originally developed simulation tools, materials, and rapid cycles of design and process optimization.

Examples of diffuser

Cultivated through our glass engineering innovations, we can fabricate various types of diffusers. The Figures below show some examples designed for different wavelengths and diffusing shapes.

Square

Rectangle

Circle

These Figures show tailored intensity profiles. For details or if you have any questions, please get in touch using the form at the bottom.

Flat-top intensity profile

1/cosnθ intensity profile

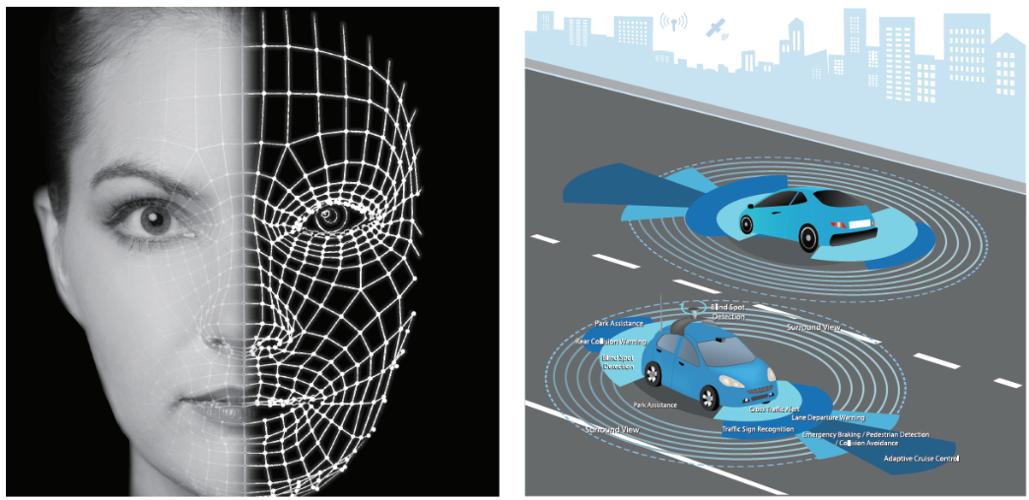

Applications in 3D sensing

In recent years, 3D sensing technologies have been applied in distance measurement face unlock, online payment, security, automotive, LiDAR, etc. Each application requires different metrics, and stereo vision, structured light, and time of flight (TOF) are widely used depending on the applications as summarized in the Table.

Structured light technology reconstructs projected patterns created by shadow mask or DOE. TOF technology uses diffuser, and it measures light travelling from a light source, hitting a target, and reflected back to a sensor.

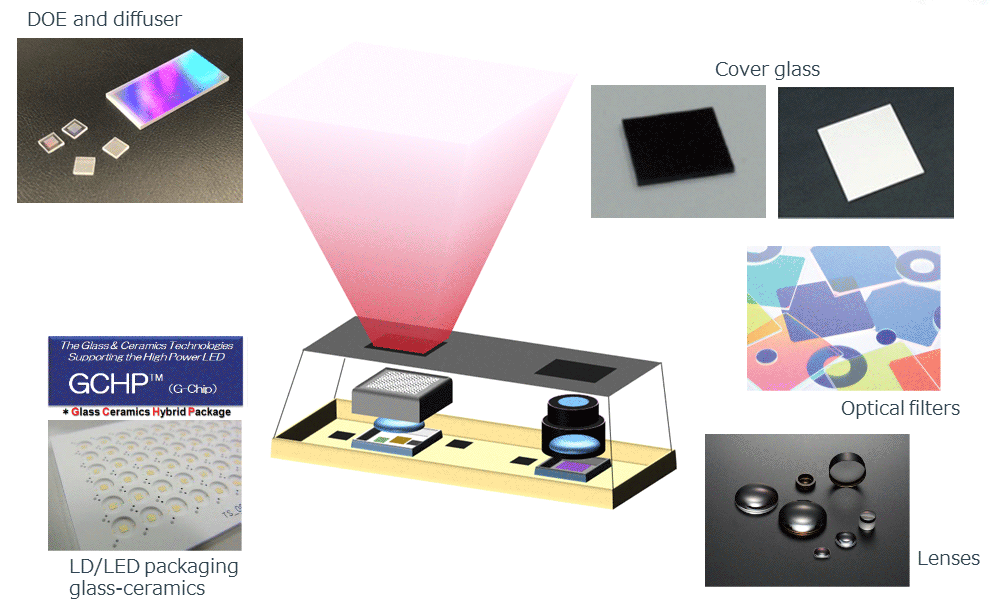

In AGC, we are providing various solutions for 3D sensing (e.g. IR transmitting cover glass, optical filters, and lenses) as well as DOE and diffuser. The figure below shows how our technologies are used in 3D sensing applications.

AGC products used for 3D sensing

Table 3D sensors comparison and related AGC products

| Stereo vision | Structured light | Time of flight (TOF) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| principle | triangulation | pattern geometric reconstruction |

direct depth measurement |

|||||||||

| applications | gesture sensor AR/VR/MR |

face unlock gesture sensor industrial AR/VR/MR LiDAR |

3D depth mapping gesture sensor LiDAR |

|||||||||

| We can customize optical components for various applications. Please inquiry from the form below. |

||||||||||||

| AGC products | Light control | waveplate | DOE & diffuser | |||||||||

| focus / collimate | lens | |||||||||||

| cover materials | Strengthened glass, IR pass glass | |||||||||||

| IR filter | multi-layer coating | |||||||||||