Silicon carbide (product name: ROICERAM™-HS) has characteristics of high purity, high strength, low thermal expansion and excellent acid resistance and heat resistance. We have over 30 years of experience as a supplier of parts for semiconductor manufacturing furnaces mainly in high temperature process. Our technologies accumulated in the semiconductor market have led to applications in LED, solar cell, SiC power device in recent years.

Applications

- Material for semiconductor production equipment (Si, SiC power device, high temperature oxidation/diffusion furnace, and LPCVD furnace)

- Material for LED manufacturing device (MOCVD furnace)

- Material for solar cell production equipment (High temperature diffusion furnace)

- Structure material for precision optical device

- Aerospace industries, etc.

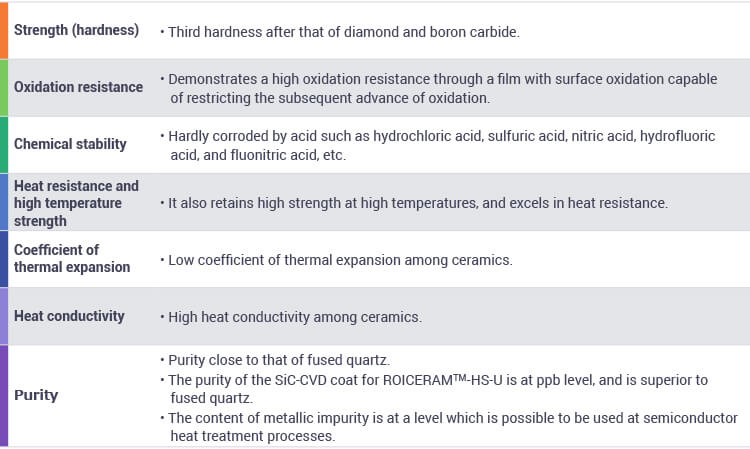

About Silicon Carbide

It is a compound in which silicon (Si) and carbon (C) are bound together, and is classified as a ceramic. It has high hardness third to diamond and boron carbide, and excels in heat resistance and chemical stability, oxidation resistance, and heat conductivity.

Feature of ROICERAM™-HS

Physical property data of ROICERAM™-HS

| Property | Unit | U grade |

|---|---|---|

| Bulk density | kg/㎥ | 3.0×103 |

| Flexural strength | MPa | 230 |

| Young's Modulus | GPa | 366 |

| Coefficient of thermal expansion | 10-6/℃ | 4.4 |

| Thermal conductivity | W/(m・K) | 180 |

| Specific heat | J/(kg・K) | 0.7×103 |

| Volume resistivity (20℃) | Ω・cm | 1×10-1 |

- Data is for reference only.

Technological development

AGC’s SiC has a track record over 30 years as a material for semiconductor production equipment mainly used at high temperatures, and has recently been adopted for the application of LED, solar cell, and SiC power devices as well, while making use of various technologies which were fostered through the experiences; (1) Connecting technology which enables a complicated structure, (2) Precision processing technology which enables precision on a micron order, (3) SiC film deposition technology with a method of vapor phase growth (CVD: Chemical Vapor Deposition). Additionally, SiC is expected to be applied in the fields of atomic energy, nuclear fusion, and aerospace. AGC is addressing technological development in pursuit of the possibility of new applications that include them.

Connecting technology

Enable a complex structure

Precision processing technology

Enable precision on a micron order

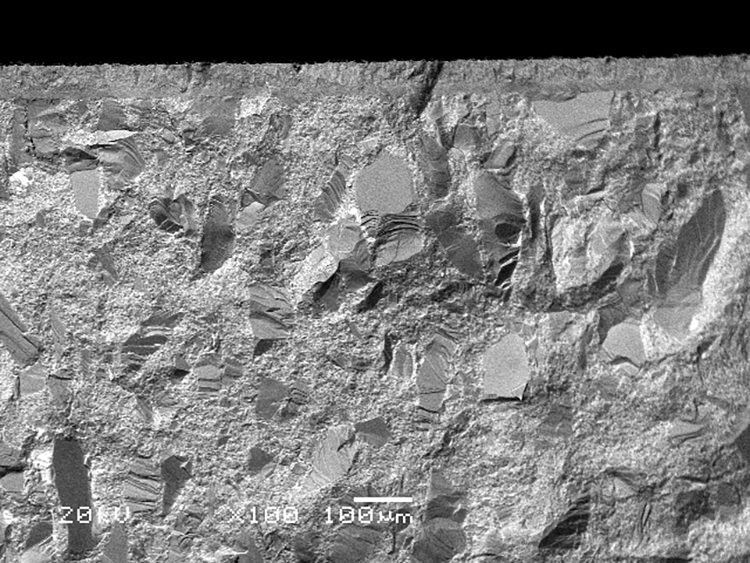

Film deposition technology

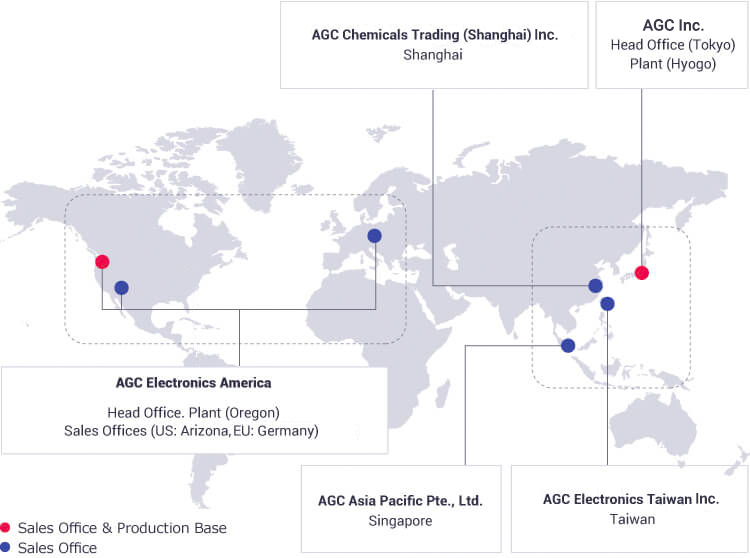

With a method of vapor phase growth (CVD: Chemical Vapor Deposition)Sales Offices・Production Base