January 16, 2018Products

AGC Has Developed a “Quartz Lens” for Deep Ultraviolet LEDs

Simplifying Manufacturing Processes and Reducing Capital Investment

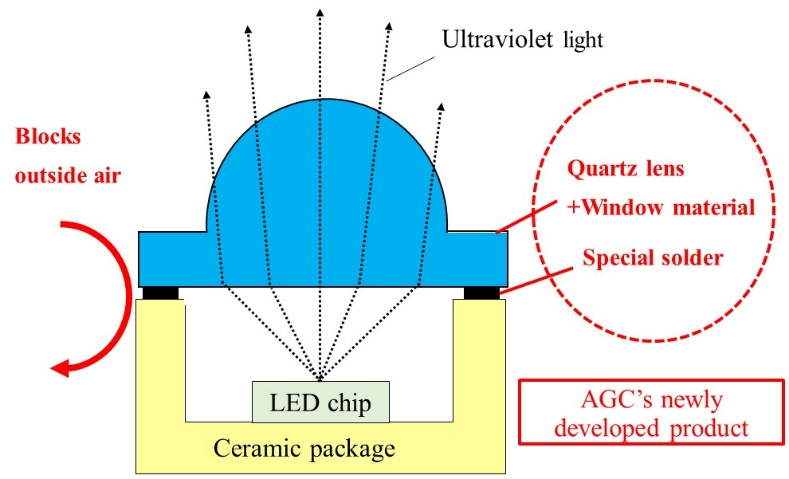

AGC Asahi Glass (AGC), a world-leading manufacturer of glass, chemicals and high-tech materials, has developed quartz lens for deep ultraviolet LEDs (Fig.1). With this product, deep ultraviolet LED manufacturing processes can be significantly simplified, and capital investment can be reduced. Prototyping will begin from 3Q 2018, and mass production is scheduled to begin in 2019.

At present, disinfection of water and air is done mainly using mercury lamps. However, because mercury has adverse effects on the human body and the environment, production of mercury lamps may be greatly limited in the future under the Minamata Convention on Mercury. Deep ultraviolet LEDs have a low impact on the environment, extremely strong disinfectant action, and as such are expected to be the next generation light source that replaces the mercury lamp. Market size is projected to be 30 billion yen in 2020*1.

Fig.1 AGC’s newly developed product

Fig.1 AGC’s newly developed product

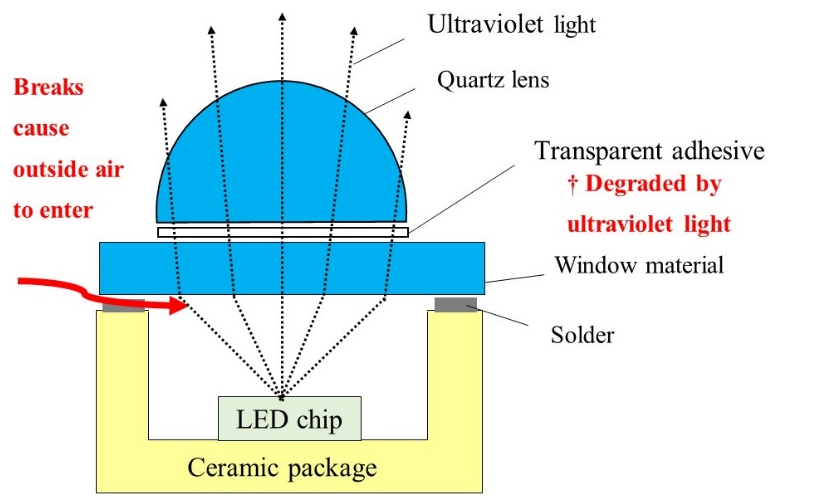

Fig.2 Current product

Fig.2 Current product

However, current deep ultraviolet LEDs (Fig.2) have some problems. One is about the transparent adhesive joining the lens and the window material. It is expensive and is easily degraded by ultraviolet light. Second is for current solder joining the package and window. Clients must have large-scale deoxigination equipment at the time of hermetic sealing, and ultraviolet LED products have the risk of cracking and air leak because current solder is hard so thermal stress due to difference of CTE between package and window directly attack the interface of package and window.

In order to solve these problems, AGC Asahi Glass has newly developed quartz lens for deep ultraviolet LEDs (Fig.2). This product integrates the quartz window material and the lens with AGC’s proprietary technology so a transparent adhesive is not required. In addition, the special solder developed by AGC is already overlaid so clients can join lens and cavity by simply heating and pressing in the atmosphere, without large-scale deoxigination equipment. Furthermore, AGC’s “special solder” is soft so make ease the thermal stress due to difference of CTE between package and window. So it will not crack or allow air leak. By these means, deep ultraviolet LED manufacturing processes can be greatly simplified and capital investment can be reduced.

Under its AGC plus management policy, the AGC Group is committed to creating products that add “security, safety, and comfort” to customers with “new value and functionality.” We will utilize the entirety of the electronic components technology we have cultivated over many years to provide high value-added products globally.

*Notes

1) Source: Fuji Chimera Research Institute 2017 LED related market survey

REFERENCE

Exhibition Summary

| Event: | 47th NEPCON JAPAN Semiconductor and Sensor Packaging Technology Exhibition |

|---|---|

| Summary: | Annual Electronic-related Manufacturing Exhibition and Event |

| Venue: | Tokyo Big Sight (Japan) |

| Period: | January 17th (Wed.) to January 19th (Fri.), 2018 |

| Booth number: | East Hall 3 E27-47 |

| URL: | http://www.nepconjapan.jp/en/About/Outline/ |

- Media inquiries

- Kazumi Tamaki, General Manager, Corporate Communications & Investor Relations Division

AGC Asahi Glass - Contact: Yuki Kitano

- TEL: +81-3-3218-5603

- E-mail: info-pr@agc.com