December 3, 2020Products

AGC Develops Glass Package for Edge-emitting Laser Diodes

Helping customers simplify their manufacturing processes and extend the life of laser products

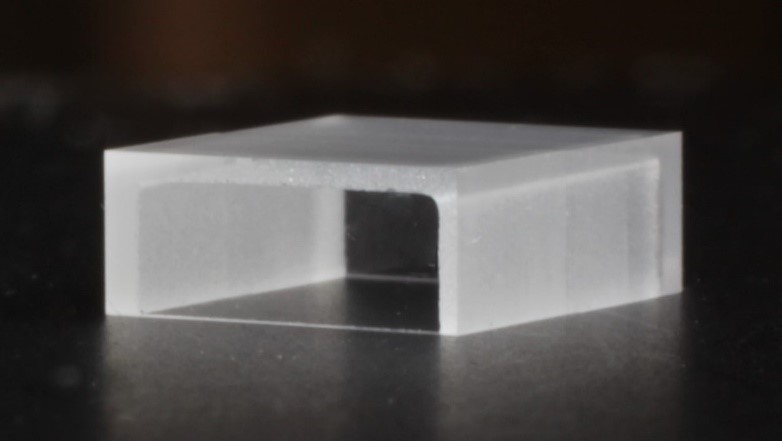

AGC Inc.(Headquarters: Tokyo; President: Takuya Shimamura), has developed a glass package that is ideal for encapsulating edge-emitting laser diode (LD) chips (Figure 1). Since both sides of this product are polished surfaces, the light emitted from the LD chip can be efficiently extracted without additional parts such as a prism mirror. In addition, by adding proprietary hermetically solder developed by AGC, simplifies customers' manufacturing process and contributes to extending the life of their laser products. This glass package is currently in the prototyping phase and AGC is aiming for mass production.

Taking advantage of high power and little spreading, lasers are used in a wide range of fields, including information devices, medical equipment, and industrial processing machines. The laser light source has a structure in which the LD chip, which is an optical component (light emitting element) that emits light in a specific direction, is encapsulated in a package. Inside of the package is kept dry to prevent deterioration of the LD chip.

Most of current LD chips are "edge emitting type" that emit light to the lateral direction from the edge face. Besides, most of the package has a window only on the top face. As a result a separate prism mirror is necessary to extract light from the LD chip upward, making it difficult to reduce costs and minimize the package size ((1) in Figure 2). Another current solution is bonding the polished window on the side hole of the package. Since bonded with sealing material, it is difficult to attach the window at the precisely right angle so as to project light in the target direction. ((2) in Figure 2)

AGC has developed a new glass package to help to resolve these issues (Figure 1). This product is box-shaped with an aperture on the bottom side and has the following advantages. The light can be efficiently projected from side of the packege in the targeted direction without using additional parts or bonding a polished surface window.

・The glass package is equipped with polished surface windows on the both sides, and the precisely right angle between the polished window and the emitted light is led to designed optical path without refracting. It also ensures excellent airtightness because the windows are a part of the package, integrated without using any sealing material.

・Since the opposite surface of the polished window is also transparent, the user can see and check the inside of the package even after sealed.

Furthermore, by adding a special hermetic solder developed by AGC to the frame surface of the aperture, the process of sealing with the ceramic substrate can be completed simply by heating and pressing in the air. This eliminates the need for large-scale deoxidization equipment for the customer. In addition, this special solder is soft enough to reduce the thermal stress generated due to difference of CTE between package and window. This helps to prevent deterioration in airtightness from cracks at the interface after thermal cycle test. As a result, this also contributes to extending the life of the laser package.

AGC has already filed for a patent for this glass package.

Enlarged picture of the newly developed glass package

Enlarged picture of the newly developed glass package

- MEDIA INQUIRIES

- Kazumi Tamaki, General Manager, Corporate Communications & Investor Relations Division

AGC Inc. - Contact: Momoyo Nakanishi

- TEL: +81-3-3218-5603

- E-mail: info-pr@agc.com