December 21, 2020Management

AGC Provides Proprietary "Causal Chain Analysis" Method for Defining Business Issues to the JX Nippon Mining & Metals Group

Used as a case study at Shiga University's Faculty of Data Science

AGC (Headquarters: Tokyo; President: Takuya Shimamura) has announced that it has provided its proprietary "Causal Chain Analysis" method for defining business issues to JX Nippon Mining & Metals (JX NMM) Group (President: Seiichi Murayama) and supported its implementation.

In recent years, making effective use of the massive amounts of complex big data has become crucial for companies to increase its competitiveness. Although there are many methods for analyzing big data, such as using statistics, AI, and IT, there have been numerous cases in many industries where big data cannot be used effectively because the business issues that are the premise for the analysis itself are not appropriately defined.

By supporting the introduction of causal chain analysis at JX Nippon Tomakomai Chemical, a member of the JX NMM Group, AGC has successfully found the optimal operating conditions for a combustion facility more easily than by conventional data analysis. This implementation example will be used as a case study of manufacturing process analysis using causal chain analysis at a seminar of Professor Kaoru Kawamoto at Shiga University's Faculty of Data Science.

A combustion facility at JX Nippon Tomakomai Chemical

A combustion facility at JX Nippon Tomakomai Chemical

Reference Information

■About Causal Chain Analysis

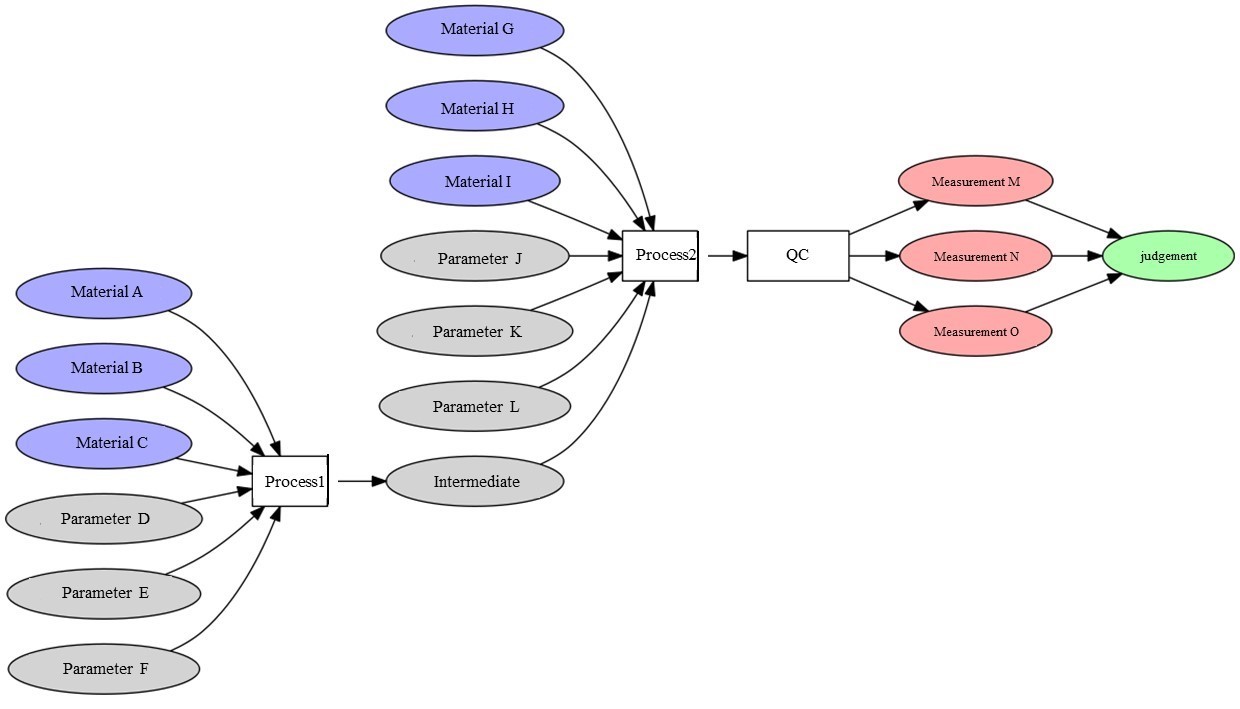

Causal chain analysis is a method that organizes and visualizes factors that can lead to problem solving from a “causal chain” perspective, including tacit knowledge based on individual experiences and intuition that cannot normally be verbalized. By visualizing the relationships between various factors, consensus on defining business issues can be formed more easily and what data should be analyzed can be clarified. Causal Chain Analysis is performed using the following procedure.

(1) Understand business processes: Interview experts and create a causal chain diagram (see the figure below). Share information accurately.

(2) Confirm available data: Mark what data is readily available, what data that will take time and resources to acquire, and what data has not yet been acquired.

(3) Set issues: Identify what data is important for business improvements and decision-making.

Example of a causal chain diagram in a chemical plant (schematic diagram)

Example of a causal chain diagram in a chemical plant (schematic diagram)

- MEDIA INQUIRIES

- Kazumi Tamaki, General Manager, Corporate Communications & Investor Relations Division

AGC Inc. - Contact: Yuki Kitano

- TEL: +81-3-3218-5603

- E-mail: info-pr@agc.com