January 13, 2022R&D

Ammonia Combustion Technology Development Project including AGC Selected as NEDO-Commissioned Project

—Aiming to achieve net zero carbon by 2050 with innovative glass melting technology—

AGC Inc.(AGC), a world-leading manufacturer of glass, chemicals and high-tech materials, has been selected by the New Energy and Industrial Technology Development Organization (NEDO) as a contractor for the project: "Development of Fuel Ammonia Combustion Technology for Industrial Furnaces". AGC will develop this project jointly with Taiyo Nippon Sanso Corporation, National Institute of Advanced Industrial Science and Technology (AIST), and Tohoku University from the end of December 2021 to March 2026.

One of the challenges in achieving Japan's goal of "Net Zero Carbon by 2050" is to reduce CO2 emissions in the manufacturing processes of the materials industry. At present, fossil fuels such as natural gas and heavy oil are used in the melting process of raw materials for glass production so there is an urgent need to develop combustion methods using fuels with low environmental impact.

This project focuses on ammonia, which does not produce CO2 when burned, is already widely distributed as a fertilizer and industrial raw material, and has the same storability and transportability as propane. An ammonia-oxygen combustion burner will be installed in the architectural glass production facility at the AGC Yokohama Technical Center to conduct demonstration tests of ammonia combustion technology. In addition to evaluating the effects of ammonia combustion on glass and the materials that comprise the melting furnace, AGC and its partners will develop a burner that can meet environmental standards and aim to deploy it in glass melting furnaces on a full scale. In the future, the project will consider expanding the applications beyond glass to other materials manufacturing processes, such as steel and aluminum.

Glass melting furnace used for demonstration tests

Glass melting furnace used for demonstration tests

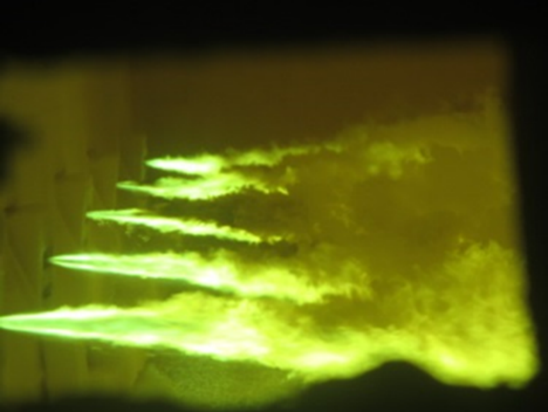

Inside a glass melting furnace

Inside a glass melting furnace

The AGC Group has designated the promotion of sustainable management as one of the priority issues in its AGC plus-2023 medium-term management plan and has set a target of net zero GHG emissions from its business activities in 2050. To date, AGC has implemented a variety of measures to reduce GHG emissions from the glass manufacturing process, including the introduction of an oxygen combustion system with high melting efficiency, fuel conversion from heavy oil to natural gas, and the introduction of electric boosters for melting. AGC will continue to contribute to the realization of a sustainable global environment through the supply of products and technologies that contribute to the reduction of GHG emissions, energy saving, and energy creation.

Reference

■Overview of the NEDO project

| Name: | Development of fuel ammonia utilization and production technology / Development of combustion technology for fuel ammonia in industrial furnaces |

| Project overview: | Contributing to decarbonization in the industrial sector by developing technology for burning ammonia in industrial furnaces, where technology for using fuel ammonia has not yet been established |

| Parties scheduled to implement: | AGC Inc. Taiyo Nippon Sanso Corporation National Institute of Advanced Industrial Science and Technology Tohoku University |

| Project period: | FY2021 to FY2025 (5 years) |

■AGC's initiatives to date

AGC is undertaking the following initiatives to reduce GHG emissions from the glass melting process.

- Media inquiries

- Chikako Ogawa, General Manager, Corporate Communications & Investor Relations Division

AGC Inc. - Contact: Kitano

- TEL: +81-3-3218-5603

- E-mail: info-pr@agc.com