Device configurations with high heat releasing and excellent reliability are required to support the recent increase in light emitting diode (LED) and laser diode (LD) output.

Electronic devices such as MEMS also need to be highly reliable.

AGC provides ceramic package substrates that meet various characteristics as well as high heat releasing and reliability, and ceramic package-related products such as lids and sealants in various shapes and with high hermeticity, using proprietary technologies cultivated over many years.

What is a Ceramic Package?

Electronic devices such as LEDs/LDs and MEMS require various electronic components, electrical wiring, and other parts such as substrates, lids, and sealants. Ceramics are used as part of the material for each of these components, and the packaging is called a ceramic package. Packages for electronic components must have certain qualities, for example, shock resistance, high heat releasing,shape suitable for a purpose, and be easy to inspect, while offering environmental adaptability (SDGs) and be in stable supply at low prices. Especially in recent years, the operating frequency of electronic components such as semiconductors is higher as is their current consumption, so packages with thick and short connection terminals with low current resistance and parasitic capacitance and high heat releasing are required. Furthermore, package components for mobile devices, etc., must also be compact.

AGC provides ceramic package substrates with excellent thermal resistance characteristics that meet these requirements, as well as ceramic package-related products such as lids and sealants.

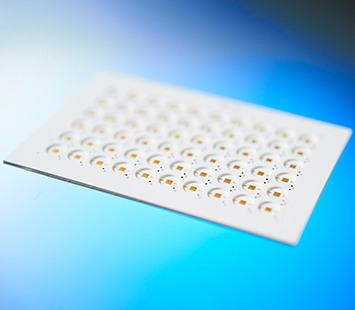

GCHP™(Glass Ceramics Hybrid Package) substrates

GCHP™(Glass Ceramics Hybrid Package) substrates

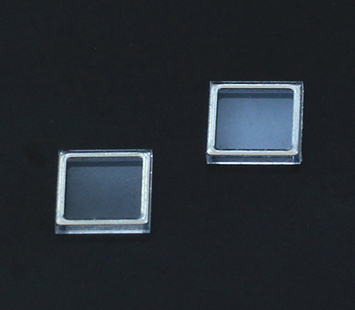

Low Temperature Hermetic Sealing Part

Low Temperature Hermetic Sealing Part

Glass Frit

Glass Frit

Types and Applications of Ceramic Substrates for Packages

Ceramics, which are widely found in the world in the form of pottery, glass, cement, and concrete, are hard and electrically insulating and also have very good corrosion and thermal resistance. In addition to these characteristics, ceramic substrates for packaging applications are becoming an essential item as the demand for miniaturization and high reliability of various electronic devices increases.

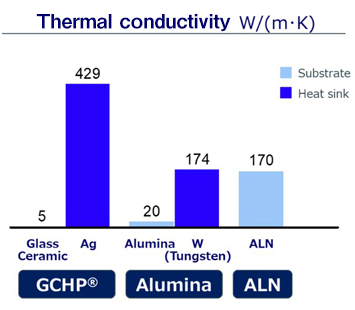

Materials used for ceramic substrates include alumina (Al2O3) and aluminum nitride (AlN), as well as silicon nitride (Si3N4) and alumina zirconia (Al2O3/ZrO2). Materials with high thermal conductivity are used for package substrates, where heat releasing is important. For example, aluminum nitride has a higher coefficient of thermal conductivity than alumina.

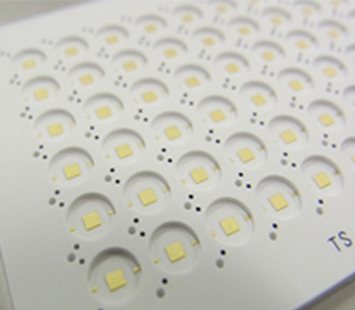

Ceramic substrates with a heat sink structure are also often used as substrates for packages with high heat releasing. Using a metal material with high thermal conductivity as a heat sink material can greatly improve heat releasing. AGC's ceramic package substrates are characterized by the ability to form blocks of silver (Ag) with extremely high thermal conductivity inside, and this heat sink structure achieves high heat releasing. In addition, since multilayering is easy and internal layer wiring and 3D circuits can be formed, they can be used for flexible designs such as miniaturization of packages and packages with surface-mounted devices.

Ceramic substrates are used in a wide variety of applications, including high-power LEDs and LD light sources, laser processing machines, radars and antennas, RF modules and other high-frequency measurement devices, Peltier devices, piezoelectric sensors, and power semiconductors.

Among these, AGC deals in many ceramic package-related products suitable for LED/LD light sources, MEMS, all-solid-state batteries, and other applications.

LED Types and Package Configuration Examples

Light emitting diodes, or LEDs, are available in a variety of types depending on the application. While visible light LEDs are well known for their use in lighting fixtures and signal lights, ultraviolet LEDs, which utilize light in a wavelength band invisible to the human eye, are used as light sources for banknote identification and for sterilization. Infrared LEDs used in remote controls for TVs and other devices also employ light in a wavelength band invisible to the human eye.

Figure. Applications of LEDs by wavelength band

| Ultraviolet LED | Visible Light LED | Infrared LED |

|---|---|---|

| ・Resin curing ・Sterilization ・Water purification ・Medical lighting ・High color rendering lighting ・Light sources for exposure equipment (substitutes for mercury lamps) etc. |

・In-vehicle lighting ・Indoor and outdoor lighting ・Lighting for roads and tunnels ・Substitutes for mercury lamps ・Street lights ・Security lighting ・Medical lighting etc. |

・Driver monitors ・Surveillance cameras ・Sensing cameras ・Night vision ・Gesture recognition ・Communication lamps etc. |

AGC's ceramic package substrates have high reflectivity not only in visible light, but also in the region from ultraviolet rays to infrared rays. Therefore, it is possible to reflect light from the back of the LED on the substrate to increase luminance in the frontal direction and has competitive advantages as a package substrate while providing high performance for LED products using any wavelength band.

In addition to package substrates, AGC can propose various package-related products and technologies used in many aspects of electronics (insulation, hermetic sealing, protection, etc.), such as lids in flat or cavity shapes, methods that enable low-temperature sealing, and sealants that do not require metallization or gold plating on the device substrate.

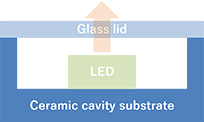

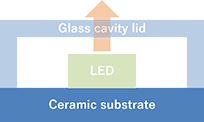

Figure. Examples of LED package configurations that AGC can propose

| Type of Lid | Ultraviolet LED | Visible Light LED | Infrared LED |

|---|---|---|---|

| Flat plate type lids |

|

||

| Cavity type lids |

|

or

or

|

|

| Available Sealing Methods | |||

| AGC solder Au-Sn solder |

AGC solder Au-Sn solder Glass frit |

||

In addition to the above configurations, it is also possible to integrate a dome lens into the lid to control light distribution with minimal loss and to add diffusion and low reflection properties as needed. We are flexible toward handling requests, so please feel free to contact us using the forms below.

Types of Semiconductor Lasers and Examples of Packaging

Semiconductor lasers, also called laser diodes (LDs) or diode lasers, taking advantage of their features such as compact size, high conversion efficiency, and high directivity, are used in optoelectronic devices such as optical pickups, optical equipment, optical communication equipment, printing equipment, laser processing equipment, medical equipment, and the like. Like light-emitting diodes, semiconductor lasers must be selected for the wavelength and output (power) appropriate for the application.

Figure. Applications of LDs by wavelength region of synchrotron radiation

| Ultraviolet LD | Visible Light LD | Infrared LD |

|---|---|---|

| ・Gas analysis ・DNA and cell analysis ・Local sterilization ・Healthcare ・Machining devices etc. |

・In-vehicle lighting (headlamps) ・Projectors ・Optical pickups ・Printers ・Testing equipment etc. |

・3D sensing and various sensors ・Optical communication ・Autonomous driving (LiDAR) ・Time of flight (ToF) cameras ・Machining devices ・Healthcare etc. |

AGC's ceramic package substrates can be designed to provide the high heat releasing required for the higher output power of laser chips seen in recent years for edge emitting lasers (EELs), vertical cavity surface emitting lasers (VCSELs), and other types of semiconductor laser structures. In particular, VCSELs used for 3D sensing in autonomous driving systems, etc., require high heat releasing characteristics and high reliability. This is bringing AGC's ceramic package substrates into the spotlight. For 3D sensing such as LiDAR, stray light can be suppressed by using a black type with low reflectance instead of a white type with high reflectance.

Furthermore, their high hermeticity makes them suitable for ceramic packages for various gas sensors, MEMS sensors, and other applications requiring hermetic sealing.

AGC's ceramic package substrates are fabricated using the low temperature cofired ceramic (LTCC) process. Patterns are formed on green sheets with silver (Ag) or other metals, stacked, and then sintered. The ability to easily create multiple layers allows for internal layer wiring and the formation of 3-dimensional circuits. This also allows for flexible design, such as miniaturization of packages and packages with surface-mounted devices.

In addition to package substrates, AGC can propose various package-related products and technologies used in many aspects of electronics (insulation, hermetic sealing, protection, etc.), such as lids in flat or cavity shapes, methods that enable low-temperature sealing, and sealants that do not require metallization or gold plating on the device substrate.

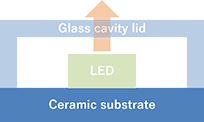

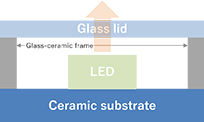

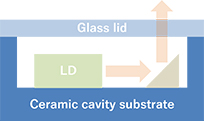

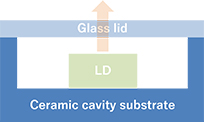

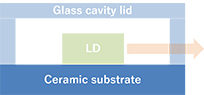

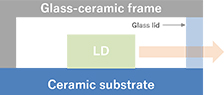

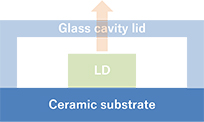

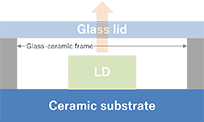

Figure. Examples of LD package configurations that AGC can propose

| Type of Lid | Edge Emitting Laser (EEL) | Vertical Cavity Surface Emitting Laser (VCSEL) |

|---|---|---|

| Flat plate type lids |

|

|

| Cavity type lids |

or

or

|

or

or

|

| Available Sealing Methods | ||

| AGC solder Au-Sn solder Glass frit |

AGC solder Au-Sn solder Glass frit |

|

In addition to the above configurations, it is also possible to integrate a dome lens into the lid to control light distribution with minimal loss and to add diffusion and low reflection properties as needed. We are flexible toward handling requests, so please feel free to contact us using the forms below.