Heat generated increases in high power LED applications.

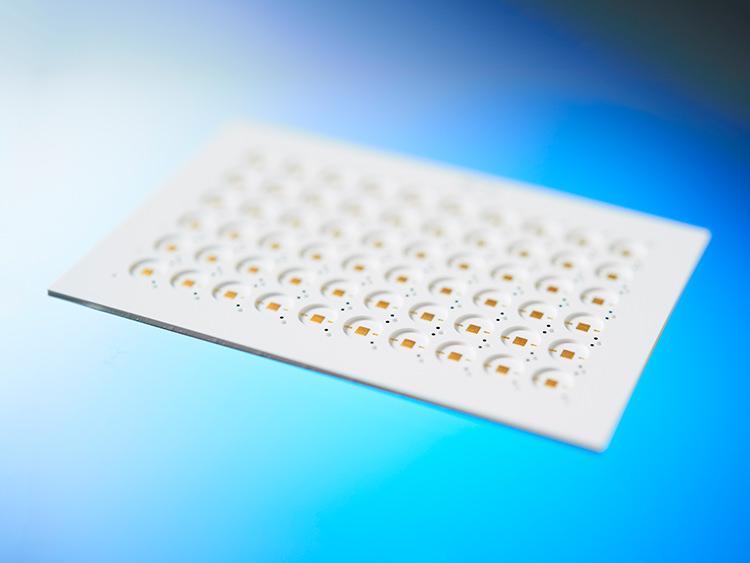

However, GCHP™ improves the durability of LEDs through a wide range of wavelengths, including the IR~UV bands and enables them to be used for high-power applications, as they are more reliable than conventional resin and alumina substrates in terms of heat dissipation and discoloration. In addition, its reflectivity is 20% higher than that of alumina substrates, so intensity may be increased effectively.

GCHP™ heat release performance can increase the output power which supports the growing demands in semiconductor lasers market

Applications

- Visible LED

automobile, residential and commercial lighting, interior and exterior lighting, traffic road, tunnel lamps, replacement of Hg lamps, security lighting, medical light, etc. - IR LED

driving monitor, security cameras, sensing camera, night vision

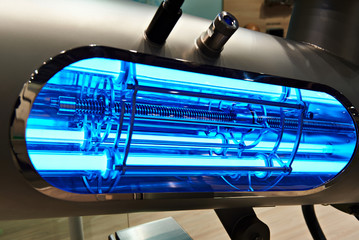

gesture recognition, communication lamp, etc. - UV LED

resin curing, sterilization, water purification, medical lamp,

color rendering, etc. - Semiconductor Laser(EEL/VCSEL)

headlamp, projector, 3D sensing, ToF camera,

autonomous driving system (LiDAR), etc. - Others Various electronic devices

Devices for optical communication, MEMS sensor, Secondary battery・All solid state battery etc.

Water purification

(UV-LED)

Headlump

(visible LED)

Sensors on Autonomous

driving (VCSEL)

GCHP™

【Characteristics】

- Integrated development from glass material to finished products

- Product lineup with high reflection (white substrate) and high absorption (black substrate)

- High heat release efficiency for high power applications

- Package size reduction capability by 3D circuit integration (multilayer)

- High reliability realized by glass (no color change)

- High hermetic properties of dense glass

- Prevention of solder cracking by glass

GCHP™

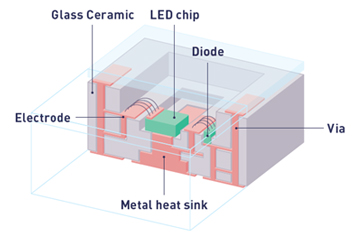

GCHP™ (Glass Ceramics Hybrid Package) is a newly developed glass ceramic packaging substrate combining of LTCC(Low Temperature Co-fired Ceramics) and advanced AGC glass material technologies.

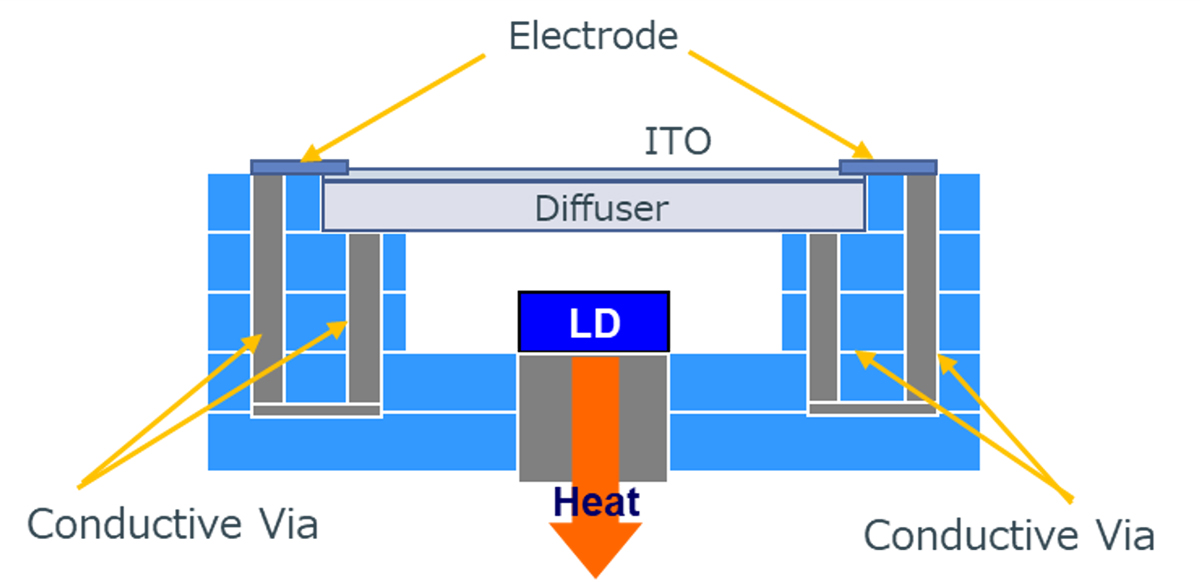

GCHP™ has various advantages as mentioned above. Using the high reflectivity, high reliability and high heat release efficiency, it is suitable for automotive exterior lighting (headlight). GCHP™ also has high reflectivity outside visible spectrum, it is also suitable for high power UV-C LED and NIR LED where demands are rapidly increasing for next generation devices. We can design GCHP™ packaging for edge emitter laser (EEL), surface emitting laser (SEL) and vertically cavity surface emitting laser (VCSEL). Our design is most suitable for the recent market trend requirement of high output power . Especially VCSEL, which attracts increasing attentions for 3D sensing and LiDAR, requires high heat release performance and high reliability, so that it is also one of the suitable applications of GCHP™.

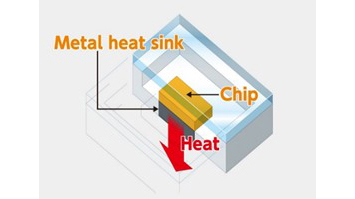

High heat releasing for high-power applications

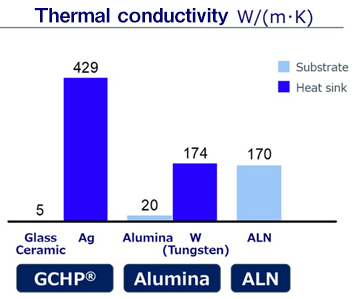

Heat releasing is a very important factor for high-power LDs to prevent laser beams from becoming unstable when they heat up. LTCC substrates themselves generally have low heat conductivity, but GCHP™ can have an Ag (silver) block in it, and the Ag block has high heat conductivity. That is the advantage of GCHP™ substrates. This heat sink structure gives a high heat releasing performance.

When making substrates using Al2O3 (alumina), a commonly used substrate material, they must be fired at a high temperature. So, it is impossible to use conductor materials having high thermal conductivity, such as Cu (copper) and Ag (silver), and this makes it impossible to achieve high heat releasing. GCHP™ uses Ag and can effectively release heat.

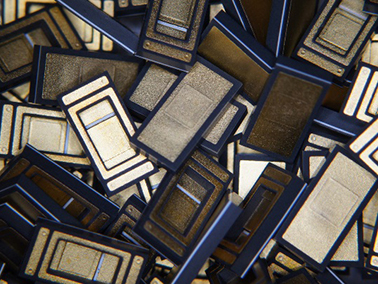

Product lineup with high reflection and high absorption

Light has the property of reflecting off at interfaces of materials with different refractive indices. Because GCHP™ is a hybrid material of glass and ceramics, reflection is repeated at interfaces between glass and ceramics, and that is why it has high reflection characteristics. We have developed a glass composition that can incorporate a large amount of ceramic filler while maintaining the glass network structure, and this has made it possible to manufacture highly reflective package substrates.

The level of reflectivity a substrate must have depends on the design of the optical sensing device. AGC provides both white and black GCHP™ substrates: the former has high reflectivity, while the latter has low reflectivity.

High reliability ensured by glass composition

| Crack suppression |

Since GCHP™ contains glass components, it has a low Young's modulus. In such a substrate, stress is dispersed without being concentrated on a part. This characteristic is not found in ceramic substrates, and is effective in preventing cracks not only in the substrate but also in the peripheral parts of the mounted substrate. |

|---|---|

| Ultraviolet light resistance |

LiDAR systems are expected to be used outdoors and must have UV resistance. GCHP™, a composite of glass and ceramics, hardly deteriorates when exposed to ultraviolet irradiation. |

| Sulfur resistance |

There is a stringent test called the sulfur resistance test to check the durability of package substrates. Package substrates must pass the test when they are assumed to be used for outdoor or automotive applications. GCHP™ does not deteriorate even under a sulfur-containing environment. |

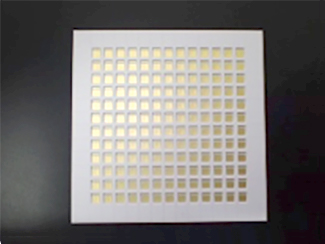

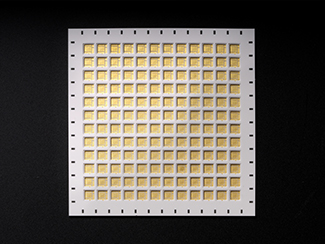

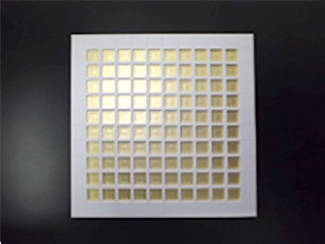

Diverse design realization and miniaturization by 3D circuit formation

GCHP™ substrates are fabricated in accordance with the LTCC process. A metal pattern, such as Ag, is formed on an unfired substrate called a green sheet, and the substrate is fired after being multilayered. This process make it possible to form inner layer wiring and produce a three-dimensional circuit. As a result, it becomes possible to downsize the package size and to flexibly design package substrates including surface-mounted ones.

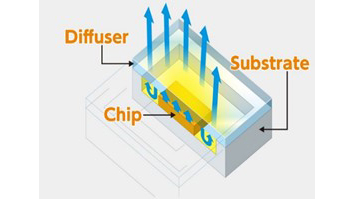

In sensing applications, GCHP™ substrates are used in combination with optical elements such as diffusers.AGC provides solutions including optical elements such as lenses, diffusers, and DOEs.

Another chip can be mounted on separate wiring from that of the chip in the center to control the characteristics of devices mounted on the surface.

Performance comparison of ceramic package substrates

The features of GCHP™ are compared to those of other ceramic materials. Since Ag functions as a heat sink, GCHP™ has high heat releasing performance.

By making use of the characteristics of glass and ceramics as the materials used, it has high reliability.It is an LTCC product that takes advantage of the characteristics of glass and ceramic as materials, and has high reliability.

Furthermore, GCHP™ allows more complicated inner layer wiring, which contributes to flexible and high-density designs.

| Item | GCHP™ | Al2O3 | AlN |

|---|---|---|---|

| Heat release | Excellent (heat sink) |

Average | Excellent |

| Reflectance (High reflectance) |

Excellent (White substrate) |

Good | Poor |

| Reflectance (High absorption) |

Excellent (Black substrate) |

Poor | Excellent |

| Reliability | Excellent | Average | Excellent |

| Multi-layer structure | Excellent | Average | Poor |

Sample

Please use our contact form to request samples.

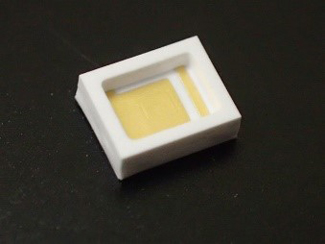

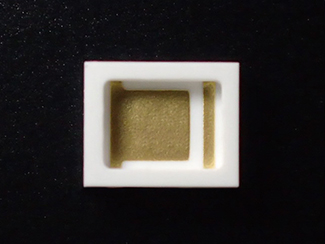

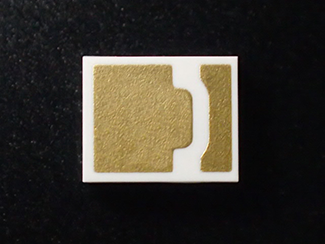

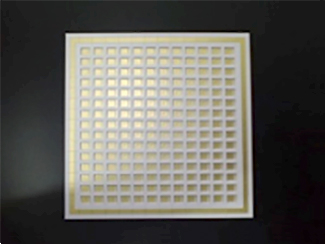

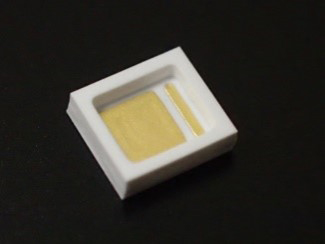

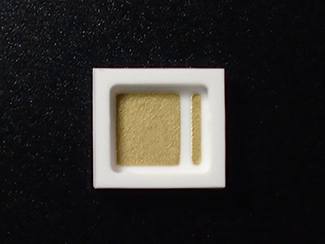

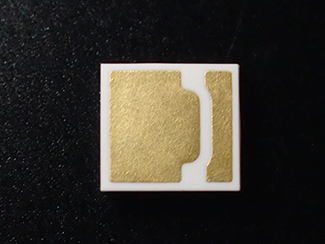

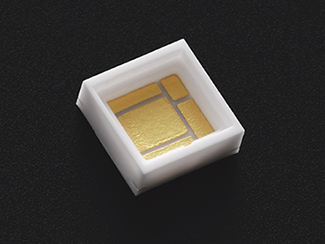

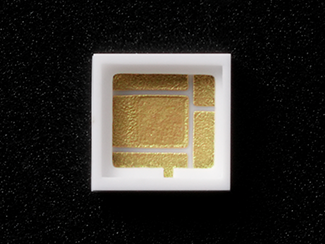

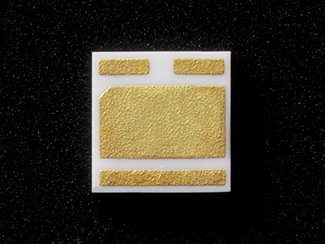

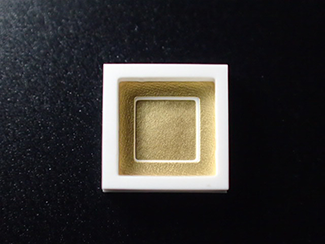

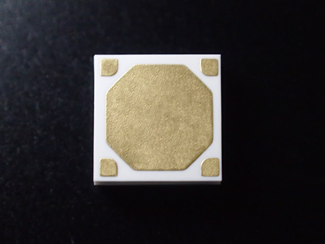

| Unit design | Top of unit | Bottom of unit | Array design | |

|---|---|---|---|---|

| 3528 size (3.5㎜*2.8㎜) |

|

|

|

|

| 3532 size (3.5㎜*3.2㎜) |

|

|

|

|

| 3535 size (3.5㎜*3.5㎜) |

|

|

|

|

| 4343 size (4.3㎜*4.3㎜) |

|

|

|

|