The synthetic fused silica glass AQ series is a high-purity, high-quality functional material based on AGCʼs abundant experience accumulated over its long history of technological R&D in fine glasses, fine chemicals, and fine ceramics.

Applications

- Lens material for Semiconductor lithography system

- Lens material for FPD lithography equipment

- Optical parts for various semiconductor manufacturing and measurement equipment

- Micro Optics (DOE, Microfluidics, etc...)

- High power laser processing machine

- UV-LED, Xe Excimer lamp

- High Frequency Device

AProduction method and Features of AQ series

AGC’s Synthetic Fused Silica AQ series is manufactured by the VAD method. The VAD method can reduce Si-OH content, providing customers with synthetic fused silica with the following features.

Features

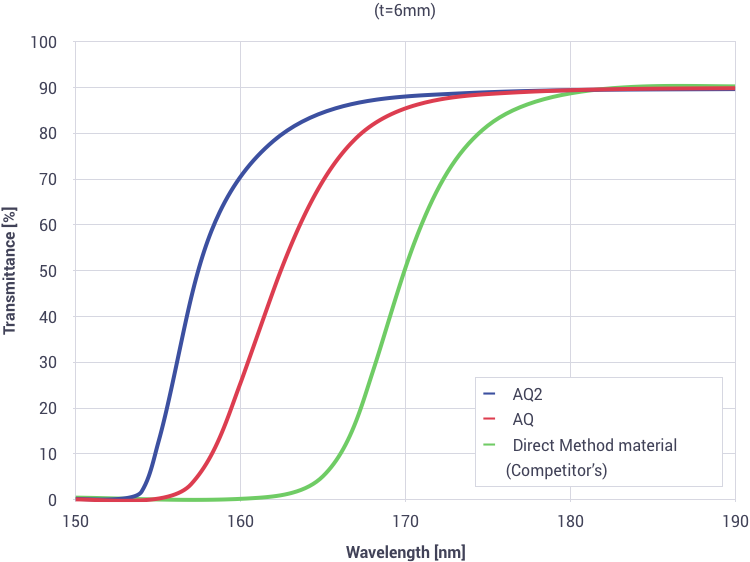

- High transmittance for deep ultraviolet rays with frequencies < 200 nm ranging from the i-ray to KrF, ArF, or Xe excimer lamps, and even for near infrared rays *1

- Excellent Compaction/Rarefaction and Polarization Induced Birefringence(PIB) characteristics*2

- Resistant to heat processing around 1000°C*3

- Excellent durability against high-energy laser beams

- Thermal expansion as low as 1/10 that of conventional glass

- High uniformity

- Very high purity, very low metal impurity content

- Low OH group content

- Outstanding chemical resistance

- Low dielectric loss

- *DUV-absorption due to electron transition and IR-absorption caused by Si-OH vibration are both reduced.

- *No rarefaction can be seen in silica glass having low SiOH content such as AGC silica glass. In addition, some ArF excimer laser exposure tests indicate low SiOH containing silica glass has good compaction and PIB characteristics. AGC has installed excimer laser exposure test lines to estimate long-term durability of silica glass. AGC has been diligently researching and developing based on a wealth of the exposure results for a long time.

- *Decrease in SiOH content makes the Si-O-Si binding network rigid and viscosity high, and consequently makes the heat resistance of silica glass high.

Typical Characteristics

| Chemical constitution | SiO2 | wt(%) | 100 |

|---|---|---|---|

| Thermal properties | CTE | ppm/K (50 to 200℃) | 0.6 |

| Softening Point | ℃ | 1600 | |

| Annealing Point | ℃ | 1120 | |

| Strain Point | ℃ | 1060 | |

| Optical properties | Refractive Index | nD | 1.46 |

| Chemical properties | Acid Resistance | mg/cm2 | 0.000 |

| Alkali Resi | mg/cm2 | 0.032 | |

| Mechanical properties | Density | g/cm3 | 2.20 |

| Young’s Modulus | GPa | 74 | |

| Knoop Microhardness | kg/mm2 | 540 | |

| Electrical properties | Bulk Resistivity | log(Ω・cm) at 200℃ | 12.5 |

| Dielectric Constant | at 1MH,R.T. | 4.0 |

- Data is for reference only.

Transmittance in Deep Ultraviolet Range

- Data is for reference only.

Product lineup

SDS (Safety Data Sheet) DownloadSynthetic quartz glass substrate

AGC provides polished synthetic quartz products based on high-quality starting materials and advanced technologies of ultra-high-precision processing, polishing, and cleaning. Typical specifications are shown below.

Processing with higher

precision is also possible.

| Wafer | □Substrate | |

|---|---|---|

| Dimension | Φ2"、3"、4"、5"、6"、8"、12" | □4"、5"、6" |

| Dimension tolerance | ±0.05~0.3mm | ±0.05~0.5mm |

| Thickness | 0.2~3mm | 0.25~10mm |

| Thickness tolerance | ±0.005~0.05mm | ±0.02~0.2mm |

| Surface roughness(Ra) | 0.5~2nm | 0.2~2nm |

| Warpage | 10~100µm | 0.5~100µm |

| Total thickness variation (TTV) | 1~20µm | 5~20µm |