Towards a Nature-friendly Society

Fundamental Approach

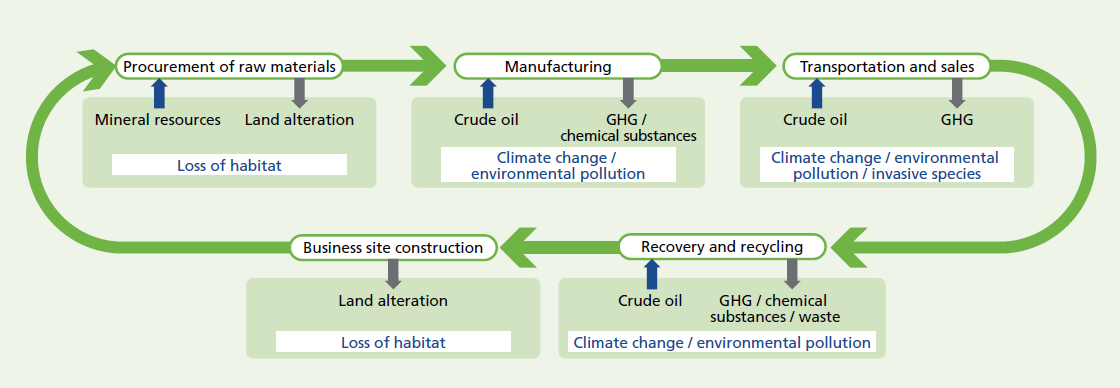

Natural capital, including biodiversity, is one of the management resources that underpin the value creation of the AGC Group. We recognize that maintaining the soundness of natural capital is essential for our business continuity, so we are striving to minimize our environmental impact by managing the impact factors of our business activities on natural capital throughout the value chain. Based on this thinking, we are promoting activities to realize a society in harmony with nature by identifying issues from various perspectives such as preventing environmental accidents, proper use of water, and reduction of pollutants. We are also setting mid- to long-term goals while aiming to achieve short-term KPIs. In addition to minimizing any negative impacts, we aim to contribute to recovery of natural capital.

The AGC Group's Relationship with Natural Capital and Biodiversity

In order to provide an overview of the dependence and impacts of the AGC Group's operations on natural capital and biodiversity, we conducted an analysis of the Group's direct operations utilizing tools such as ENCORE provided by the Natural Capital Finance Alliance, the Biodiversity Risk Filter (BRF in the table) provided by WWF, and the Materiality-Screening-Tool (MST in the table) provided by the Science Based Targets Network. It became clear that the operations of our main product categories (manufacturing of glass and basic chemical products) have an impact on the ecosystem due to dependencies on water resources, resource extraction, GHG emissions, waste emissions, and the release of pollutants (into air, water, and soil).

The AGC Group's Relationship with Natural

Relationship between the Value Chain and Impacts on Nature

| AGC's activities | Natural capital impacts and dependencies shown by each tool | Targets | Indicators | |||

|---|---|---|---|---|---|---|

| ENCORE | BRF | MST | ||||

| Dependencies | Water use | Ground water / Surface water |

Water scarcity | - | Not set | Water intake by business and water source |

| Impacts | Water use | Water use | - | Water use | ||

| GHG emissions | GHG emissions | - | GHG emissions | Reduce Scope 1, 2, and 3 emissions by 30% by 2030 compared to 2019 | GHG emissions | |

| Waste | Solid waste | - | Solid waste | Final landfill ratio of less than 1% in 2025 | Waste volume, final landfill ratio | |

| Pollutants | Non-GHG air pollutants / Soil pollutants / Water pollutants |

Pollution | Soil pollutants / Water pollutants |

Not set | Appropriate management of pollutant emissions and chemical substances contained in our products | |

| Mineral resource extraction/Land use | Terrestrial ecosystem use | Tree cover loss | Use of terrestrial ecosystems, freshwater ecosystems, and marine ecosystems | Not set | Not set | |

Industrial Safety and Security

Fundamental Approach

The AGC Group, which develops its businesses in local communities, believes that ensuring safety and security is a major prerequisite for achieving sustainable growth. Based on this belief, the AGC Group has established the AGC Group Industrial Safety & Security Policy to promote various issues surrounding industrial safety and security.

Management Structure

In addition to striving to prevent accidents and other crises, such as unforeseen accidents,

the AGC Group is working under the AGC Group Industrial Safety & Security Policy to prevent the escalation of accidents that do occur by promoting countermeasures to deal promptly and accurately with such crises.

The Group promotes risk reduction and preventive measures in its business activities by applying a PDCA cycle. Each business division promotes fire prevention, countermeasures for industrial safety accidents,

and risk assessments for natural disasters based on action plans drawn up for that year from the EHSQ General Division.

In addition to these measures, the Group strives for continuous improvement through internal audits that monitor the extent to which the above measures have been carried out.

In the Chemicals Business, the Chiba Plant and the Kashima Plant have been certified to utilize high-pressure gas by the Ministry of Economy, Trade and Industry.

To promote a higher level of voluntary safety at business sites certified to utilize high-pressure gas,

AGC has established a safety management system headed by the CEO and with the general manager of the EHSQ General Division and the president of Chemicals Company as the officers in charge of safety.