AGC Ceramics

The business of AGC Ceramics originated in 1916 when Asahi Glass Co., Ltd. began the production of bonded refractories in Amagasaki.

Subsequently, we became the first in Japan to successfully produce fused cast refractories and alumina cement.

Since 1969, we have been centrally producing various types of refractories, including fused cast, bonded, and monolithic refractories, at the current Takasago Plant.

In 2002, we were spun off from Asahi Glass to establish Asahi Glass Ceramics Co., Ltd., and in 2007, the company name was changed to “AGC Ceramics Co., Ltd.”

Today, we have affiliated companies such as AGC Plibrico Co., Ltd., Zibo AGC Alumina Materials Co., Ltd (China), AGC Plibrico (Dalian) Industries Inc. (China), and AGC Ceramics Singapore Pte. Ltd. (Singapore).

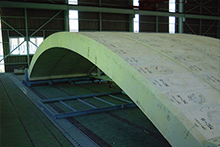

We are engaged in the production of various refractories, fine ceramics, and engineering businesses.

Location: Head office/ Shiba 4-1-23, Minato-ku, Tokyo 108-0014, Japan

Takasago plant/ Umei 5-6-1, Takasago City, Hyogo, 676-8566, Japan, Located in the AGC Takasago plant (Amagasaki Factory)

Capital: ¥3,500 million

Representative: Masaru Ota

Employees: 275 (as of May 2024)

Main business activities: Production and sale of refractories and fine ceramics; design and installation of glass kilns and other industrial furnaces; and sale of accessories for these

Environmental Performance Data

| 2020 | 2021 | 2022 | 2023 | 2024 | ||

|---|---|---|---|---|---|---|

| Air | GHG (1,000 of tons) |

9 | 9 | 9 | 6 | 7 |

| NOx (tons) | 2 | 1 | 0 | 0 | 0 | |

| SOx (tons) | 0 | 0 | 0 | 0 | 0 | |

| Soot and dust(tons) |

0 | 0 | 0 | 0 | 0 | |

| Water | Wastewater (1,000m3) |

86 | 83 | 78 | 81 | 120 |

| COD (tons) | 0 | 0 | 0 | 0 | 0 | |

| Waste | Waste finally sent to landfill(tons) | 144 | 177 | 197 | 119 | 171 |

Frequency Ratio of Accidents Requiring Leave

| 2020 | 2021 | 2022 | 2023 | 2024 |

|---|---|---|---|---|

| 0.00 | 0.00 | 0.00 | 3.16 | 0.00 |

- The data cover all employees at the operating site (including business partners).