AGC paves the way to improved driving safety with innovative windshields

- #Mobility

AGC has developed the world's first*1 FIR sensor-enabled windshield for vehicles, an innovation that is expected to enhance driving safety. Integrating FIR sensors into ADAS (advanced driver assistance systems) compensates for the limitations of visible light sensors, while sensor fusion technology merges data from both systems to vastly improve visibility. Ultimately, AGC aims to use its experience and knowledge to eliminate all pedestrian traffic fatalities.

*1 According to an AGC study

Profile

Kenji Kitaoka

FIR windshield project leader Manager of All AGC business promotion team Marketing group

Mobility Business Development Office Automotive company

Yoji Yasui

Coating team Functional Components Department

Materials Integration Research Institute Technology headquarters

Mitsuyoshi Kobayashi

Evaluation science team manager Common Platform Technology Department

Advanced Technology Research Institute Technology headquarters

The automotive industry is expected to deploy ADAS on wide scale in the near future. Using artificial intelligence and other high-tech solutions, ADAS helps mitigate human error and could ultimately eliminate most if not all traffic accidents.

However, the technology still needs to grow. Night vision accuracy in ADAS, for example, requires further development. In the United States, approximately 80% of pedestrian fatalities in traffic accidents occur at night.

"With expertise in material sciences, we are adding new features to existing auto components," says Kenji Kitaoka, who led AGC’s FIR windshield project at the company's Mobility Business Development Office. "As such, we can help advance ADAS and contribute to the reduction of traffic accidents."

Recently, his project team collaborated with the company's own labs to develop the FIR windshield, which transmits both visible and far-infrared light, enhancing ADAS' visual recognition.

Kenji Kitaoka,FIR windshield project leader Manager of All AGC business promotion team Marketing group Mobility Business Development Office Automotive company

Cameras in ADAS mainly depend on visible light, with an optical capability nearly identical to that of the human eye. But this means it shares the eye's limitations. For example, at night ADAS can only detect objects within the range of the headlights -- approximately 40 meters at low beam and 100 meters at high beam. This increases the chance of accidents when speeding down dark roads. Moreover, the headlights of oncoming vehicles create a backlit scene, hampering the ability of ADAS to discern details and recognize objects. Similar limitations occur during the day when driving into a low or setting sun. Exiting tunnels can also confuse ADAS cameras due their limited dynamic range. In addition, the ADAS cameras cannot function under poor visibility conditions due to fog or other bad weather. These are the same shortcomings of the human eye.

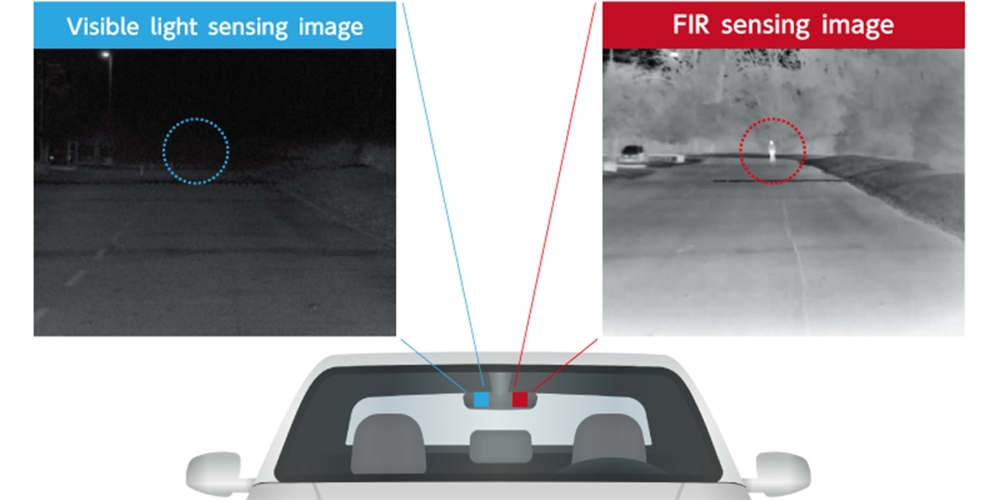

FIR sensors excel at detecting people at night or in dark settings, surpassing human eyesight. This is done by reading infrared light from the human body and contrasting it with the surroundings (Figure 1). The heat signature of humans and animals differs from structures and trees, allowing FIR sensors to distinguish humans from their surroundings. This heightened visibility, commonly referred to as "night vision," is often integrated into ADAS as an option that complements visible light sensors.

Figure 1 FIR sensors capable of detecting pedestrians beyond the reach of headlights

FIR sensors can detect pedestrians up to 120 meters away, beyond the reach of high beams and the visible light sensors commonly used in ADAS. The image in the diagram shows the test results of a collaboration with Hitachi Astemo, demonstrating the combined usage of visible light and FIR sensors.

For aesthetic reasons, car designers have tended to position FIR sensors lower on a vehicle such as inside the front grille or near the front bumper, while visible light sensors are typically placed higher such as behind the front windshield.

"[The lower position] has hindered FIR sensors from detecting people at a distance at an earlier stage. Additionally, when the sensors are installed low to the ground, a special mechanism is required to clean their lenses, thereby increasing overall cost," explained Kitaoka. According to him, the current method of placement undermines the potential and usability of FIR sensor technology.

The automotive industry has recently shown a great deal of interest in sensor fusion, a process that combines data from different types of sensors to create a detailed image of the driving environment. To improve the accuracy of sensor fusion, the visible light and FIR sensors should be placed roughly adjacent to each other. If placed too far apart, ADAS has to compute the different perspectives before giving an accurate assessment, straining the system's processing capability.

Besides FIR sensors, other options for sensor fusion include lidar, millimeter-wave radar, and near-infrared (NIR) sensors. Lidar is excellent for gauging distances and in performing point cloud calculations, making it valuable for map matching and self-vehicle localization required for autonomous driving levels 3 to 5. However, it has problems detecting pedestrians in dark clothing and small animals. Millimeter-wave radar provides less detailed point cloud data compared with lidar and is difficult to install on the front windshield due to its size. NIR sensors require special illumination and have limited range.

FIR sensors, on the other hand, can detect the heat emitted by animals, easily detecting pedestrians in two-dimensional images. In addition, it can be utilized even in vehicles compatible with autonomous driving level 2.

There are numerous advantages of having both visible light and FIR sensors behind the windshield. However, FIR sensors are typically placed outside the vehicle due to their being nonfunctional behind regular windshields, which prevent FIR light from passing through.

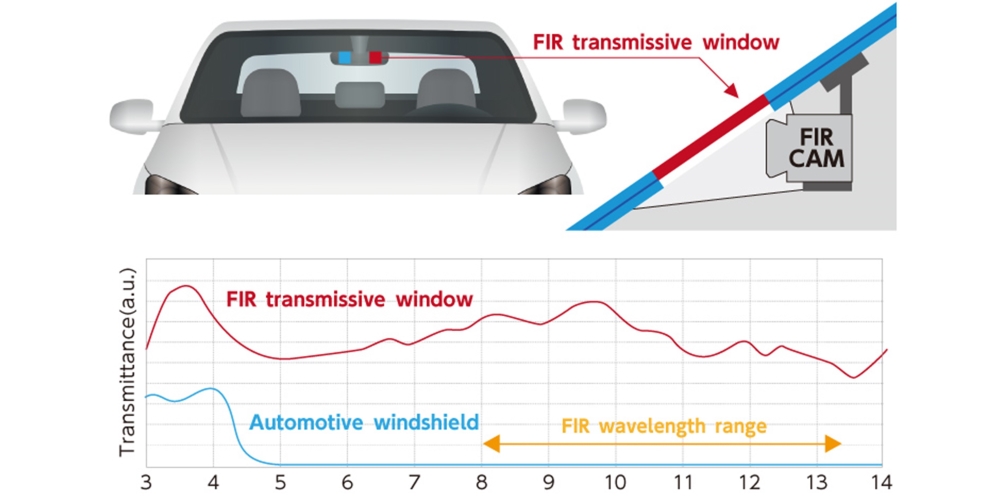

Existing windshields are made of materials that together allow transmission of about 70% of visible light to ensure high visibility for drivers. However, these materials block FIR light, which has a wavelength of between 8 μm to 14 μm – longer than that of visible and near-infrared light. To install an FIR sensor inside the car, windshield glass must be made of a different material. However, there is no single one that meets all requirements in terms of optical performance, strength and size.

AGC's new FIR windshield allows for the installation of sensors for both visible light and FIR behind the front windshield. This was achieved by replacing part of a regular windshield with certain material that enables FIR transmission. (Figure 2).

Figure 2 Making the impossible possible with an innovative design

AGC's FIR windshield incorporates a special material that transmits FIR, seamlessly integrated with the regular front windshield. This design enables the installation of both visible light and FIR sensors within the windshield.

The new FIR-capable windshield also overcomes the problem of proximity, as both visible light and FIR sensors can be placed closer together, allowing the ADAS to detect pedestrians several hundred meters away -- beyond the reach of headlights -- and activate the automatic brake system when needed. The end result is improved recognition and less false triggering of the automatic braking system. Additionally, sensors installed behind the windshield are not exposed to road dirt and grime, needing only a clean windshield to maintain optimal performance, while the risk of damage from gravel and other debris is eliminated.

Another benefit of the new windshield is that temperature readings obtained from the FIR sensor give the ADAS the means to identify road conditions including ice, markings, curbs and debris. Importantly, the ability to discern between wet and frozen roads allows for more precise ADAS performance.

Cutting out a portion of glass and fitting it with another material is difficult. While it may seem easy, at the end of the process the windshield must meet strict usage requirements including environmental resistance, reliability and safety -- a task that calls for a sophisticated level of design and manufacturing expertise.

Automotive windshields are usually made of a single material in the plane. Hence, even for AGC and its wealth of experience, the development and manufacture of the new automotive glass proved challenging.

Windshields are exposed to rain, sand, dirt, heat and ultraviolet light. Simply drilling holes and fitting different materials together can result in water or noise leaks. Combining different materials can also cause the finished product to degrade due to differences in expansion caused by heat. Moreover, for safety reasons, passenger vehicle parts must be demonstrably sturdy and pass strict certification tests.

To meet these demands, AGC employed its considerable design and manufacturing prowess that comprises glass drilling, integration of dissimilar materials, airtightness, thermal management and safety measures. The shape and size of openings for embedding materials were optimized to transmit FIR. At the same time, seal integrity and long-term reliability were ensured by using resin-based sealants.

Yoji Yasui,Coating team Functional Components Department Materials Integration Research Institute Technology headquarters

"We faced our biggest challenge in ensuring long-term reliability and safety," said Yoji Yasui, a member of AGC's Coating Team at the Materials Fusion Research Institute. "At first, we didn't have the right materials for windshields that could resist scratching caused by water drops mixed with sand while withstanding the damage from UV light. Surmounting these hurdles was crucial for effectively transmitting FIR. But in the end, we managed to develop an optical coating film that not only solved the problems but also adds a touch of style by minimizing shine."

Mitsuyoshi Kobayashi,Evaluation science team manager Common Platform Technology Department Advanced Technology Research Institute Technology headquarters

AGC subjects all new glass to exhaustive testing to ensure functionality and performance. The optical properties of the FIR windshield can be degraded by water drops on the glass. Mitsuyoshi Kobayashi, manager of the Evaluation Science Team at AGC's Advanced Technology Research Institute, explained AGC's approach to overcoming this potential issue. "We installed actual FIR sensors and simulated various conditions of the front glass. Based on the evaluation, we were able to propose suitable window structures." The team also ensured that the new windshield functions properly when used with FIR sensors from different manufacturers.

AGC is accelerating the development of the FIR windshield for integration into vehicle models set to launch in 2027. "Previously, the high cost of FIR sensors posed challenges for their adoption in cars. However, at CES 2023 in January, we received feedback indicating the growing acceptance of FIR-sensor cameras in ADAS due to a notable cost reduction and improved performance. We successfully communicated the advantages of implementing the FIR windshield to those anticipating the use of FIR sensors," said Kitaoka.

As one of the largest and most visible components in a vehicle, the front windshield holds tremendous potential as a vital conduit to connecting the car with its surroundings. With the automotive industry undergoing a paradigm shift driven by the trends in “Connected, Autonomous, Shared, Electric” technology, innovation centered around the windshield has become imperative. The FIR windshield emerges as a technology that perfectly aligns with the evolving trends, offering new possibilities for the future of automotive design.

Reprinted from Nikkei xTECH Special

*Department names and titles are those at the time of the interview.