Transforming Automobiles into Rolling Abodes: AGC developed high-performance cover glass for in-car displays

- #Mobility

The relationship between cars and people has never been more different. With autonomous driving technology advancing, cars are becoming more than just a means of transportation -- they are evolving into "mobile living spaces." In-car displays are playing a crucial role in defining a vehicle's value in this era, and AGC is enhancing this value with high-quality cover glass for safe, comfortable and easy-to-use displays.

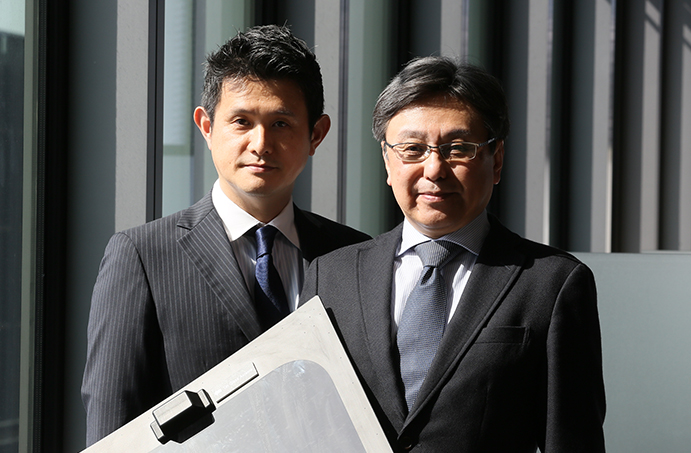

Profile

Koya Nakatsukasa

Director Sales & Marketing Department In-Vehicle Design Glass Division

Mobility General Division Automotive Company

Shinji Kobune

Chief Engineer Sales & Marketing Department In-Vehicle Design Glass Division

Mobility General Division Automotive Company

Yasuhiro Terai

Leader Process Technology Group Technology & Engineering Headquarters

In-Vehicle Design Glass Division Mobility General Division Automotive Company

Yusuke Yamamoto

Manager Sales & Marketing Department In-Vehicle Design Glass Division

Mobility General Division Automotive Company

As the Connected, Autonomous, Shared & Services, Electric (CASE) trend gathers steam, vehicles are starting to feel more like homes on wheels. Drivers will become able to get more out of their travel time, whether for work or leisure, with less focus on actually operating the vehicle. They now have access to internet services in relatively serene and comfortable surroundings compared with the past.

Koya Nakatsukasa, Director Sales & Marketing Department In-Vehicle Design Glass Division Mobility General Division Automotive Company

“Drawing upon our extensive expertise in glass manufacturing, our goal is to turn next-generation automobiles into attractive and valuable 'mobile living spaces,’” says Koya Nakatsukasa, director of AGC's Automotive Company In-Vehicle Design Glass Division of the Mobility General Division.

With vehicles looking more like mobile living spaces, certain interior attributes, such as functionality and performance, will play a vital role in defining a car's worth. In-car displays, in particular, will become indispensable to this, offering passengers a wealth of information and ensuring optimal comfort.

Traditional in-car displays were primarily designed for navigation systems. Next-generation in-car displays will provide a wider array of features, from displaying web content to allowing drivers to join online conferences.

Even before the CASE trend, in-car displays had been improving. Car navigation systems, which gained popularity in the 1990s, paved the way for the widespread use of liquid crystal displays. Initially, they were confined to a small area between the driver and passenger seats and offered as an option. But as car navigation systems grew in demand, displays grew in size to provide easy access to information. Eventually, they replaced traditional instrument panels, showing information in well-designed layouts with better visibility than their analog predecessors.

As displays grew in size, in-car interfaces started incorporating human-machine interface features, moving beyond mere display of information to include interactivity. In the early 2010s, advanced touchscreen technology from smartphones made its way into in-car displays, enabling drivers to control air conditioning and audio-visual systems via touchscreen buttons and sliders.

As in-car displays advance, cover materials for in-car displays must meet diverse and rigorous technical specifications.

“Keeping visibility high for in-car displays is quite a challenge. External lighting can change significantly based on where and when you're driving, as well as the weather,” says Shinji Kobune, chief engineer in AGC’s Sales & Marketing Department. “Plus, in-car displays also serve as touchscreens, so it's crucial to minimize any reduction in visibility due to things like fingerprints. And considering they take up a significant area of the interior, they need to look and feel top-notch in terms of quality and design. Of course, safety is our utmost priority."

Shinji Kobune, Chief Engineer Sales & Marketing Department In-Vehicle Design Glass Division Mobility General Division Automotive Company

Back when car navigation systems first became popular, in-car displays were covered with plastic for ease of manufacturing and to keep car occupants safe if damaged after an accident. However, as displays became larger and more advanced, demand dictated a shift toward a premium feel to match their growing presence in interiors. AGC met this challenge by introducing the world's first cover glass for in-car displays in 2012, providing both a sleek finish and improved touch. The innovation gained traction, starting with a German automaker.

As in-vehicle displays grew larger, a demand for curved cover glass emerged. The expansion of these displays inevitably created areas that were difficult for drivers to see or reach for touch operation. This reduced visibility and operability can distract the driver during driving and compromise safety, making curved displays with their enhanced visibility and accessibility imperative.

In 2017, AGC began manufacturing curved cover glass. Leveraging its expertise in glass technology across materials production, processing and coating, the company has swiftly developed cover glass products to meet market requirements. Currently, AGC manufactures curved cover glass for automakers in Yonezawa and Yokohama, Japan, as well as Suzhou, China, ensuring timely and consistent delivery. In the future, AGC may expand its manufacturing base into Europe.

To meet the stringent requirements for in-car display cover glass, both the glass material and film coating need to deliver high performance with anti-reflection and smudge resistant features, among others. AGC's expertise in materials development, product design and manufacturing makes this possible.

AGC employs three key technologies for developing cover glass, all of which are crucial for improving in-car displays.

The first is the 3D-forming technology essential for making curved cover glass. "In addition to over a century of glass manufacturing expertise, we applied special film-forming techniques for the coating, using fluorine-based and organic materials to quickly and optimally develop cover glass that meets the new demands," says Yasuhiro Terai, group leader of Process Technology, Technology and Engineering Headquarters.

Shaping glass is easy if it is just a matter of bending. However, transforming heated glass into precise shapes demands craftsmanship akin to the delicate artistry used for making premium sweets. This task is even more challenging for display cover glass, an industrial product requiring mass production. Achieving highly precise and reproducible processing necessitates a profound understanding of glass as a material, as well as advanced equipment and manufacturing expertise.

Yasuhiro Terai, Leader Process Technology Group Technology & Engineering Headquarters In-Vehicle Design Glass Division Mobility General Division Automotive Company

AGC utilizes a technique known as "hot bending," which involves heating glass close to melting point then bending it to achieve the desired curve. The result is precise processing of large, curved cover glass with accuracy to within 1 mm. Ensuring uniform optical properties of the cover glass surface is also crucial, as any inconsistencies can lead to distorted colors when overlaid on displays, degrading high-definition visuals. To address this, AGC has developed technology to uniformly apply coatings like low-reflection film on the surface of curved glass, enhancing display quality.

The second technology addresses safety. As in-car displays get larger, there is a risk of harm to occupants during accidents. AGC's expertise in creating high-strength glass -- as exemplified by its Dragontrail® cover glass for smartphones -- addresses this concern. It features high scratch and impact resistance to increase safety during use and in the event of an accident.

The cover glass for AGC’s in-car displays has a base material similar to Dragontrail®. Tailored for automotive use, it is thicker than glass used for smartphones and reinforced through improved processing to meet stringent safety standards. Importantly, AGC continues to improve both materials and processes to boost safety further.

The third technology involves simulations to assess visibility from the driver’s perspective. Kobune explained: "We conduct simulations to test display visibility in various weather conditions like clear, overcast, rainy and at sunrise. This helps us develop glass materials and coatings that optimize visibility."

Automakers typically use simulations to evaluate driver visibility. However, AGC distinguishes itself by using its own simulation technologies to precisely replicate transparent glass, enabling rapid response to customer needs and feedback.

As the CASE trend helps drive the evolution of automobiles, displays will have an increasingly significant impact on the value of each vehicle.

Yusuke Yamamoto, Manager Sales & Marketing Department In-Vehicle Design Glass Division Mobility General Division Automotive Company

“Expansive, high-resolution displays will span dashboards, offering a dynamic showcase of information and entertainment,” says Yusuke Yamamoto, manager in the Sales & Marketing Department. “Cover glass must not only convey information reliably, but also express it impressively." Moreover, recent auto expos showcase creative approaches like projecting textures such as wood paneling on displays to tailor in-car ambiance to individual tastes.

With its appealing aesthetics and premium tactile qualities, glass goes beyond just displays. It could also be used in other interior elements, ultimately enhancing the in-car experience. AGC is at the forefront of this pursuit, developing automotive glass with advanced functionalities to meet the growing demand for glass in car interiors. The company’s breakthrough technologies include sound generation and haptic feedback through glass, which also adds to the user experience. Furthermore, AGC possesses versatile shaping technologies that enable the integration of glass into diverse interior designs, facilitating innovative and flexible design concepts.

AGC's vision for the interior of next-gen cars: High-res displays offer diverse info and create new experiences, all anchored in glass.

“In the upcoming years, in-car display cover glass will be a defining element for auto interiors. The market will challenge us to innovate, blending insights from both the automotive and electronics industries,” says Nakatsukasa. “As a pioneer of in-car display cover glass, we are committed to leading innovation and leveraging our expertise and knowledge in chemicals, electronics and ceramics. We hope our new products will help propel the automotive industry forward."

Reprinted from editorial advertisement in Nikkei xTECH, Octorber 2023

* Department names and titles are as of the interview.