Human capital: Nurturing materials innovation for semiconductor breakthroughs

- #Electronics

- #Spirit

Semiconductors are essential for powering digital devices such as PCs, smartphones, appliances and industrial machinery. They provide superior functionality, performance and energy efficiency through miniaturization of electrical circuits. Yet their evolution depends on expertise at materials makers like AGC Group to continually enhance product offerings.

AGC has been contributing to semiconductor development by quickly bringing to market the materials needed for cutting-edge semiconductor production. Following is a look into how AGC engineers and sales representatives have leveraged the company's prowess in materials development to become a key contributor to the semiconductor industry.

Profile

Naoyuki Miura

Blanks Production Technology Group Blanks Products Division AGC Electronics

WooJin Jeon

Marketing & Business Operation Group Polishing Products Unit Advanced Materials Division

Electronic Materials General Division Electronics Company

Hiroki Takakura

Blanks Inspection Technology Group Blanks Products Division AGC Electronics

Achieving a sustainable future involves two key elements: digitalization and decarbonization. Semiconductors play a pivotal role in this goal, especially in the field of digitalization.

Semiconductors, through their associated chips, boost functionality, performance and energy efficiency. Production of advanced semiconductors requires materials crafted with technology that surpass standards in many other industries.

AGC supplies two key materials essential for chip production: extreme ultraviolet lithography (EUV) mask blanks, currently sourced globally from only two providers; and ceria slurry, a critical determinant of chip quality. Both materials showcase AGC's prowess, blending technologies with talent in the development, production and supply processes.

AGC’s capabilities in this area are made possible by its work environment, which places a premium on specialized human capital to attain objectives quickly and effectively.

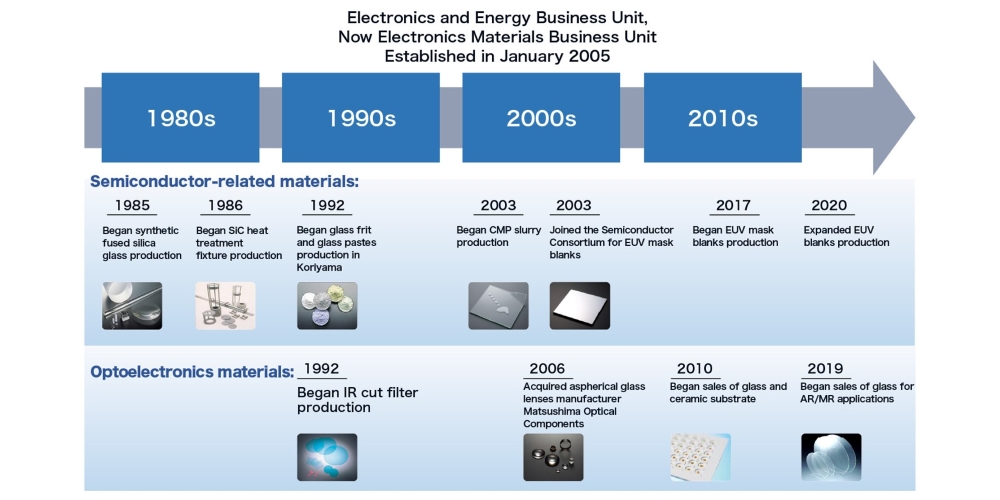

Figure 1: Products of AGC's Electronic Materials Business Headquarters

AGC delivers unique solutions thanks to a diverse product lineup that combines materials, processing and design.

EUV mask blanks, a key component that AGC supplies to semiconductor manufacturers, serve as substrates for the photomasks that are used to form intricate circuit patterns on chips. Production of cutting-edge chips with ultrafine circuitry requires precision exposure using extreme ultraviolet (EUV) light at a significantly shorter wavelength of 13.5 nanometers compared to the conventional 193 nm or longer wavelengths. This advancement requires minimizing the surface irregularities and defects of mask blanks to less than one-tenth of traditional standards.

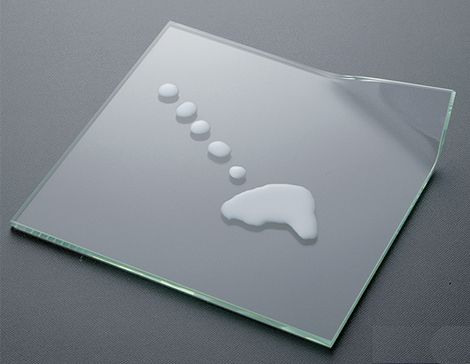

Meanwhile, ceria slurry, another key material, serves as an abrasive used in chemical mechanical polishing (CMP) to achieve an exceptionally flat surface on semiconductor wafers during their manufacture. AGC's ceria slurry is unique in that it contains fine particles of cerium oxide which acts as abrasive grains. Recently, components and wiring on chips have adopted intricate three-dimensional structures. Ensuring a level surface during manufacturing is crucial for accurately stacking patterns and forming uniformly thin films. AGC's ceria slurry plays a vital role in this process, significantly impacting chip performance and quality.

In the field of advanced semiconductors, constant technological innovation is a given. To keep pace with manufacturers in the industry, AGC must continuously enhance components like EUV mask blanks and materials like ceria slurry. The company’s organizational structure prizes human capital so that AGC can respond promptly to innovations and customer demands.

Naoyuki Miura,Blanks Production Technology Group Blanks Products Division AGC Electronics

EUV mask blanks are made by layering thin optical film onto a zero-thermal expansion glass substrate. Naoyuki Miura at AGC Electronics said, “Our strength lies in seamlessly handling the entire process, from manufacturing zero-thermal expansion glass to polishing for enhanced flatness. This achieves uniform film deposition to meet the required specifications and produce mask blanks -- from upstream to downstream."

AGC employees are afforded smooth collaboration across all departments in the development and manufacturing of EUV mask blanks. The seamless workflow allows the many different technologies needed in this exacting process to be integrated quickly and efficiently.

This smooth collaboration extends to the development of ceria slurry. “To craft high-quality ceria slurry tailored to customer needs, we internally develop and manufacture abrasive particles,” said WooJin Jeon, sales representative for ceria slurry at AGC Electronics. “Our ability to handle this in-house is highly valued by our customers in contrast to the common practice of external sourcing.”

Jeon also cites AGC's unique workplace as an advantage. The compact organizational structure ensures quick decision making within teams and fosters a cooperative atmosphere across departments that transcends roles and backgrounds.

AGC’s Hiroki Takakura,who works on inspection technology for quality assurance of EUV mask blanks, sheds additional light on the company’s strengths. “Customers have high expectations and appreciate how we ensure quality,” he said. “In this advanced tech field, we work together with them to find the best solutions. We always tackle challenges with a collaborative mindset, sharing insights from both sides.” This approach reflects a partnership that extends beyond the typical user-supplier dynamic, emphasizing trust as we navigate challenges together, he noted.

WooJin Jeon,Marketing & Business Operation Group Polishing Products Unit Advanced Materials Division Electronic Materials General Division Electronics Company

A significant number of new and seasoned professionals have moved over to AGC from other companies, attracted by a work environment that nurtures the collaborative efforts of individuals with diverse backgrounds and skills.

These professionals who were hired to staff AGC's semiconductor-related materials business saw the company’s advantages in the field. But what exactly lured them in?

AGC delved into the research and development of EUV mask blanks back in 2003. Miura shared his view, expressing: “To me, the appeal lay in the company's foresight, initiating development at a time when the significance of the technology wasn't widely recognized. The semiconductor industry undergoes rapid changes, and I sensed a corporate culture with a sharp instinct for emerging technologies, fearlessly taking on development challenges.”

Hiroki Takakura,Blanks Inspection Technology Group Blanks Products Division AGC Electronics

Takakura gave a similar reason: “Material technology development is a field where short-term results are hard to come by. Leveraging years of expertise, AGC has introduced advanced materials and components. With a long-term vision, the company is committed to ongoing investments in research and development, even when immediate results are not guaranteed. This outlook convinced me that the company was poised for continuous future growth.”

Founder of the original Asahi Glass Co. (now AGC), Toshiya Iwasaki famously said, “Never take the easy way out, but confront difficulties.” This ethos became ingrained in the company’s founding principle: Choose the difficult path, not the easy one.

Today, this spirit extends not only to the company’s original glass business but also to its electronics business.

Jeong in sales said, "I've always wanted to be on a sales team where I can create new value, not just process orders and close deals. This means having a working knowledge of marketing, business planning and overall business management."

AGC's internal environment, fostering collaboration across departments, is truly ideal for advancing work.

Figure 2: Evolution of AGC's Electronic Materials Business

Over 30 years, the company has consistently pioneered new technologies with a long-term perspective.

To get the most out of talent recruited for cutting-edge materials development, support from within the company and a collaborative workplace are crucial. How did Miura, Jeon and Takakura, along with other staff, perceive these positives after joining AGC?

“In EUV mask blanks development, agility is crucial. Even for a young professional like me, the company allows significant autonomy and instills a strong sense of responsibility, which makes work quite fulfilling," said Miura. "Of course, not everything can be handled alone. Collaboration isn't limited to my department but extends across others, facilitated by the openness of the workplace.” Additionally, robust educational programs, including voluntary training for Python programming, offer staff ample opportunities to increase their skills, he added.

AGC also wants employees to maintain a proper work-life balance. Jeon explained this: "I'm planning to take about a month of parental leave soon. The workplace culture here encourages and supports employees taking parental leave. Moreover, the department I'm currently a part of has embraced a hybrid working model, allowing for a mix of remote and in-office work. This enables me to balance work and quality time with my family. Even now, post-COVID-19, this situation hasn't changed."

Takakura is especially thankful for the location where he works. AGC Electronics’ Motomiya manufacturing and development plant is located near Koriyama, a commercial hub in the Tohoku region. "Koriyama is perfectly situated between Sendai and Tokyo, and you can easily reach Niigata with just one train ride,” he said. “I can take paid leave and enjoy a diverse lifestyle, going on short trips to various places." Besides being work-friendly, the living environment, with its shopping and leisure options, adds to its appeal, he said.

Working in the ever-changing semiconductor industry requires individuals to consistently stay abreast of changes in technology and a shifting business landscape. How do AGC employees in the semiconductor sector see their future?

"I handle sales for ceria slurry primarily used in semiconductor manufacturing. Yet, I see potential applications beyond semiconductors," Jeon said. "Many electronic components, such as sensors, share manufacturing processes similar to semiconductors. I aim to explore new applications and deliver untapped value."

Miura also wants to broaden the scope of his job. "There are various types of film deposition for EUV mask blanks,” he said. “Currently, I'm in charge of one type of deposition. But in the future, I’d like to accumulate knowledge about other deposition processes to become a professional who can oversee the entire production of mask blanks."

Takakura, however, likes AGC’s worldwide reach in the semiconductor field. “When I switched jobs, my goal was to work abroad in my 30s,” he said. "AGC's semiconductor business has a global presence, and I want to enhance my skills to make an overseas assignment happen, regardless of my current role.”

AGC prioritizes human capital with a key strategy that values diversity of thought and culture. This policy is crucial not only for maximizing organizational performance but also for nurturing the individual career paths of employees. The aspirations of its human capital always have -- and always will be -- the driving force behind AGC.

Reprinted from editorial advertisement in Nikkei xTECH, Octorber 2023

*Department names and titles are those at the time of the interview.