November 28, 2018Management

AGC to Further Expand its Supply System for EUVL Mask Blanks

AGC (Headquarters: Tokyo; President: Takuya Shimamura) has decided to further expand its production capacity of EUV lithography photomask blanks ("EUVL mask blanks") at its group company AGC Electronics (Headquarters: Koriyama, Fukushima Pref.; President: Hiromasa Sato). This expansion is in addition to the expansion announced earlier this year on February 5, and will enable AGC Group to triple its EUVL mask blank production capacity by 2020.

To respond to the approaching IoT era, in which all manner of things will be connected via internet, the sophistication and miniaturization of electronic devices will continue to advance, creating demand for semiconductor chips with faster calculation speeds, larger data capacity, and more advanced integration. The circuit patterns of semiconductor chips must be further miniaturized to achieve these goals, yet with currently available optical lithography technology*1 it is theoretically unrealistic to fabricate miniaturized patterns at what is commonly termed a "7nm" level. Therefore, EUV*2 lithography is considered the most promising technology to replace optical lithography.

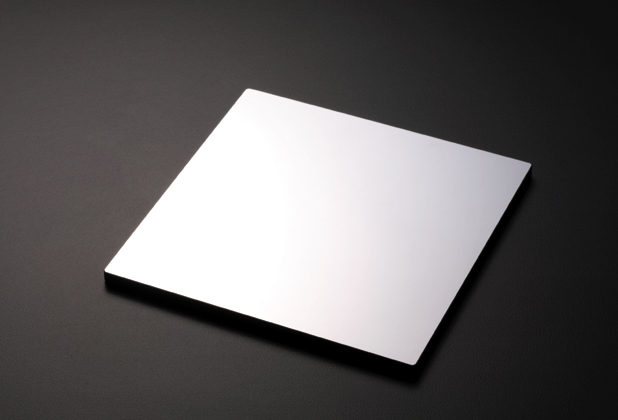

EUVL mask blanks

EUVL mask blanks

AGC began conducting R&D on photomask blanks utilized in EUV lithography technology in 2003. By combining its core technologies (i.e. glass materials, glass polishing, and film coatings), AGC is currently the only manufacturer in the world capable of handling every technology required for photomask blanks―from the glass material to film material.

In anticipation of the expansion of EUV lithography, which is expected to become the prevailing technology, AGC has decided to further expand the supply system for EUVL mask blanks at one of its group companies, AGC Electronics.

Under its AGC plus management policy, the AGC Group has made a commitment to positioning electronics related business as one of its key strategic initiatives. AGC intends to continue making aggressive capital investment in EUVL mask blanks, which are expected to see significant growth in demand in the coming years, to contribute to further development of the semiconductor industry.

- NOTES -

1: Optical Lithography Technology: The process of transferring LSI circuit patterns to silicon wafers, etc., using a KrF (krypton fluoride) or ArF (argon fluoride) light source.

2: EUV: Extreme ultraviolet radiation with a wavelength of 13.5nm.

2: EUV: Extreme ultraviolet radiation with a wavelength of 13.5nm.

- REFERENCE -

■ About AGC Electronics

| Official name | AGC Electronics Co., Ltd. |

|---|---|

| Capital | 300 million yen |

| Representative | Hiromasa Sato |

| Head office location | Koriyama City, Fukushima Prefecture |

| Employees | Approximately 600 (as of end of December 2017) |

| Primary business | Semiconductor-related materials business, optical device related business, etc. |

■ About EUVL Mask Blanks

EUVL mask blanks are a low-thermal expansion glass substrate with various kinds of optical coating films on its surface. An EUV photomask comprises a semiconductor chip circuitry pattern formed onto the surface of an EUVL mask blank, and this circuit is transferred onto a silicon wafer in order to create a semiconductor chip.

Due to the further miniaturization of circuits, EUVL mask blanks are increasingly expected to:

・ Have as close to zero micro-defects as possible;

・ Have almost perfect flatness

EUVL mask blanks are a low-thermal expansion glass substrate with various kinds of optical coating films on its surface. An EUV photomask comprises a semiconductor chip circuitry pattern formed onto the surface of an EUVL mask blank, and this circuit is transferred onto a silicon wafer in order to create a semiconductor chip.

Due to the further miniaturization of circuits, EUVL mask blanks are increasingly expected to:

・ Have as close to zero micro-defects as possible;

・ Have almost perfect flatness

- MEDIA INQUIRIES

- Kazumi Tamaki, General Manager, Corporate Communications & Investor Relations Division

AGC Inc. - Contact: Ai Ota

- TEL: +81-3-3218-5603

- E-mail: info-pr@agc.com