April 26, 2021Management

AGC Develops "Smart Inventory System" for Automated Management of Raw Materials

―Transforming business processes of purchasing administration departments with DX―

AGC Inc.(AGC), a world-leading manufacturer of glass, chemicals and high-tech materials, has developed the Smart Inventory System for the automated management of raw materials. The system was fully deployed as of April 2021 at the Kansai Plant, Takasago Factory (Takasago City, Hyogo Prefecture) and Amagasaki Factory (Amagasaki City, Hyogo Prefecture). By introducing DX into procurement operations such as inventory checks, procurement planning, and ordering, which were previously done manually, the Group will promote the handing down of technology & skill among workers and expects to reduce annual labor hours by 1,000 hours. Going forward, AGC is considering rolling out this system to other plants, with a focus on the domestic glass business in Japan.

Glass plants procure raw materials such as silica sand needed to produce glass, as well as caustic soda and hydrochloric acid used in wastewater treatment every day. To cope with complex production plans, the staff in charge has to check inventory levels every day, review procurement plans, and respond to changes in storage and usage plans. These activities were very time-consuming.

In addition, for tanks containing raw materials such as caustic soda, for which inventory used to be managed visually by people, AGC has developed a system that can remotely monitor the tank inventory and automatically place orders by installing a measuring device and converting the remaining amount into digital data.

Raw materials inventory management system

Raw materials inventory management system

Tank inventory management system

Tank inventory management system

<Notes>

*1 RFID: Radio Frequency ID. A system that can read and rewrite data by wireless communication.

Reference

The Smart Inventory System automated ordering system for raw materials consists of two systems: a raw materials inventory management system and a tank inventory management system.

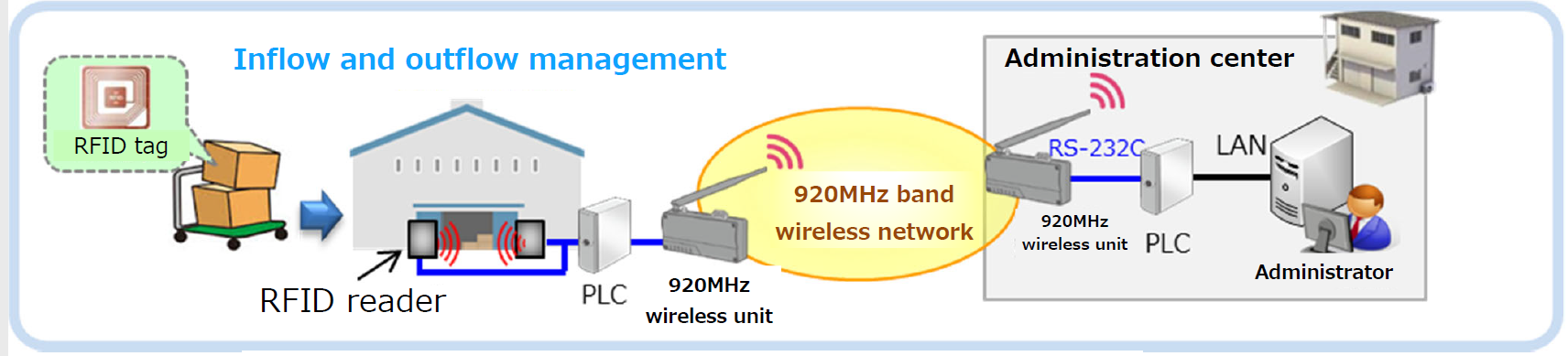

RFID sensors are installed at the entrance and exit of raw material warehouses to automatically manage the inflow and outflow of raw materials. RFID tags are attached to each raw material container for data reading in order to manage information on raw materials. Oki Electric Industry Co., Ltd. (Oki Electric Industry)'s 920MHz band multi-hop wireless "SmartHop™" is used to collect RFID tag information.

Raw material attached with an RFID tag

Raw material attached with an RFID tag

Flow of raw materials inventory management system

Flow of raw materials inventory management system

This is the name of a series of Oki products that support 920MHz wireless products with high reachability and multi-hop relay transmission. As a solution suitable for the Internet of Things (IoT), it enables a variety of sensors and devices to be easily connected to a wireless network and has been adopted in more than 120 products of partner companies.

https://www.oki.com/

*SmartHop is a registered trademark of Oki Electric Industry

■Tank inventory management system

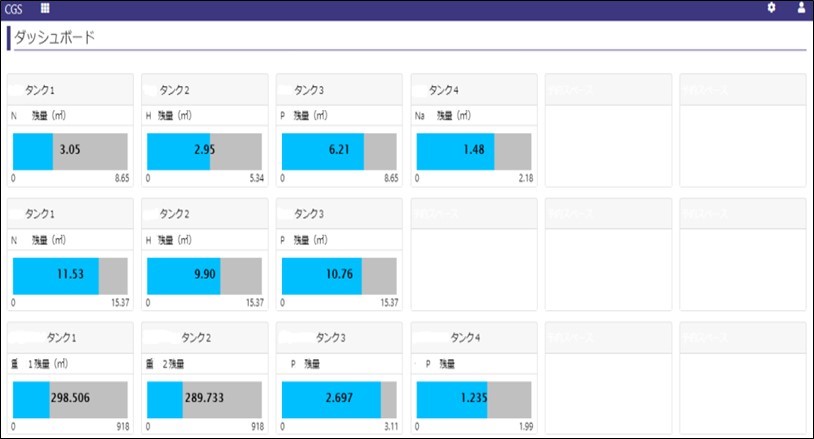

AGC has jointly developed a cloud-based inventory management system with CONTEC Co., Ltd. (CONTEC) to achieve DX in procurement operations. Users can view remaining amounts via a dashboard. This system automatically update inventory tables, and automatically place orders with suppliers. AGC has developed an IoT system that uses sensors attached to tanks and gateway devices to remotely monitor remaining amounts in tanks in real time via mobile lines. The CONPROSYS™ TM (telemeter) Series from CONTEC is used as the gateway device.

Real-time monitoring of remaining amount in tanks

Real-time monitoring of remaining amount in tanks

- MEDIA INQUIRIES

- Kazumi Tamaki, General Manager, Corporate Communications & Investor Relations Division

AGC Inc. - Contact: Kitano

- TEL: +81-3-3218-5603

- E-mail: info-pr@agc.com