July 25, 2024ProductsEnvironment & CSROthers

AGC’s Water Electrolysis Ion-Exchange Membrane FORBLUE™ S-SERIES Adopted for JAXA’s Test Model of Oxygen Generation System for Human Space Activity

AGC’s fluorinated ion-exchange membrane, FORBLUE™ S-SERIES, has been adopted for the test model of an oxygen generation system, which is one of the life support systems being developed by the Japan Aerospace Exploration Agency (JAXA) for human space habitations. The membrane has exhibited high performance in previous component tests*1 conducted by JAXA, leading to its adoption based on the evaluation results.

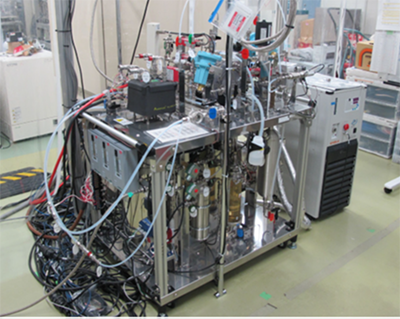

JAXA test equipment for demonstrating oxygen production(Photo by JAXA)

JAXA test equipment for demonstrating oxygen production(Photo by JAXA)

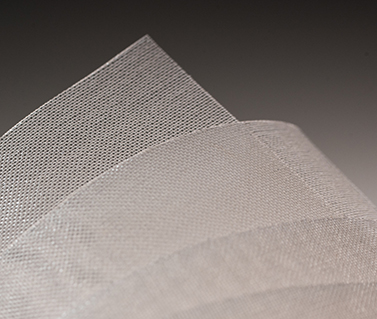

FORBLUE™ S-SERIES

FORBLUE™ S-SERIES

In this field of life support systems, research and development are accelerating for human space activities under the international space exploration program, the Artemis program*2. In the space environment where oxygen supply is essential, a device is required to regenerate water from astronaut exhalation and then utilize that water to produce oxygen through electrolysis. Equipment used in space must demonstrate high performance in terms of durability and energy efficiency, even in harsh environments. In the future, ground tests will be conducted by JAXA using the test model to confirm that the FORBLUE™ S-SERIES meets these stringent requirements.

The fluorinated ion-exchange membrane FORBLUE™ S-SERIES adopted this time is a product that is attracting attention as a water electrolysis application for green hydrogen*3 production. Leveraging AGC Group’s strengths in molecular design and membrane formation technologies, this product achieves (1) world- leading voltage performance, allowing for low electrical resistance and reduced power consumption and (2) high gas barrier performance, preventing the mixing of hydrogen and oxygen. These characteristics have been highly regarded for enabling safe and long-duration operation. The utilization of this membrane in oxygen generation systems, crucial for sustaining the lives of astronauts, is expected due to its unique properties. Furthermore, AGC has decided to construct a new production facility for FORBLUE™ S-SERIES at its Kitakyushu Site in 2026, and this plan has been recognized for ensuring a stable supply. Since both operational performance and safety are required in water electrolysis applications for green hydrogen production, our track record in space applications, which is a harsher environment, will allow customers to use the FORBLUE™ S-SERIES with confidence.

In its medium-term management plan, AGC plus-2026 , the AGC Group positions Performance Chemicals as one of its strategic businesses. Moving forward, we will contribute to the realization of a carbon-neutral society by providing high-performance ion-exchange membranes suitable for green hydrogen production. Additionally, we will contribute to the advancement of space-related technologies through the provision of unique materials and solutions.

<Notes>

*1 The process of creating a small-scale test machine that closely resembles the actual apparatus and verifying the performance of each component individually.

*2 Collective name for NASA's entire proposed international space exploration program.

*3 Hydrogen produced using renewable energy sources without emitting CO2 in the production process (Source: Agency for Natural Resources and Energy, Ministry of Economy, Trade and Industry website)

<Reference>

・FORBLUE™ S-SERIES for use in electrolysis and electrodialysis for a wide variety of applications, including PEM water electrolysis

https://www.agc-chemicals.com/jp/en/fluorine/products/detail/index.html?pCode=JP-EN-F027

- Media inquiries

- Chikako Ogawa, General Manager, Corporate Communications & Investor Relations Division

AGC Inc. - Contact: Nakajima