Micro-processed Glass

AGC has been engaged in the processing and molding of various types of glass, including quartz glass, for many years. It has also built an extensive track record while dedicating significant investment to the development of micro-processing and molding technologies. AGC can also respond flexibly to shapes that are difficult to achieve using conventional processing and molding processes.

A variety of glass processing processes

Some of the various methods of micro-processing glass are introduced below.

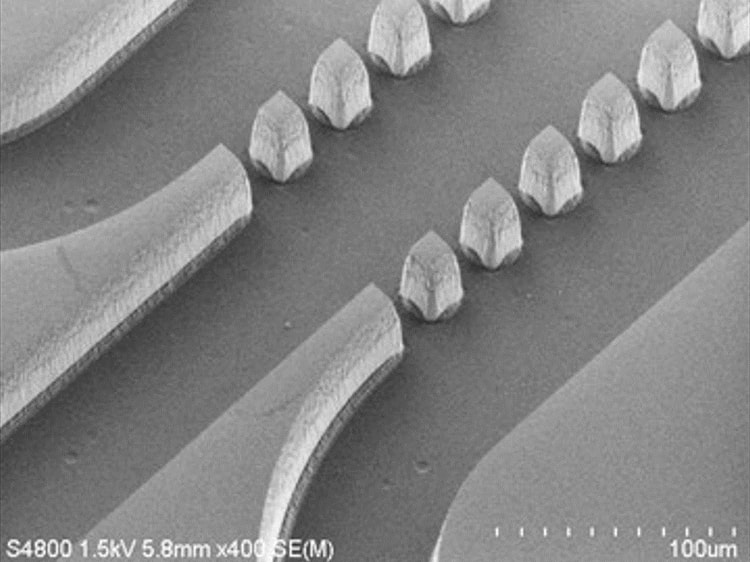

Dry etching

Dry etching is mainly used in the semiconductor production process. Under a low-pressure environment, plasma is produced from the gas used for etching, ionizing it into radicals and ions, which then collide perpendicularly with the processed surface. It is possible to create trenches and vias with cross-sectional shapes that are near rectangular by pre-forming a mask pattern using photolithography in non-etched areas and adjusting process conditions. In addition, using gas that reacts with the material to be processed makes it possible to assure the etching rate. However, vacuum equipment and exposure devices are expensive, raising the cost slightly compared to other micro-processing methods.

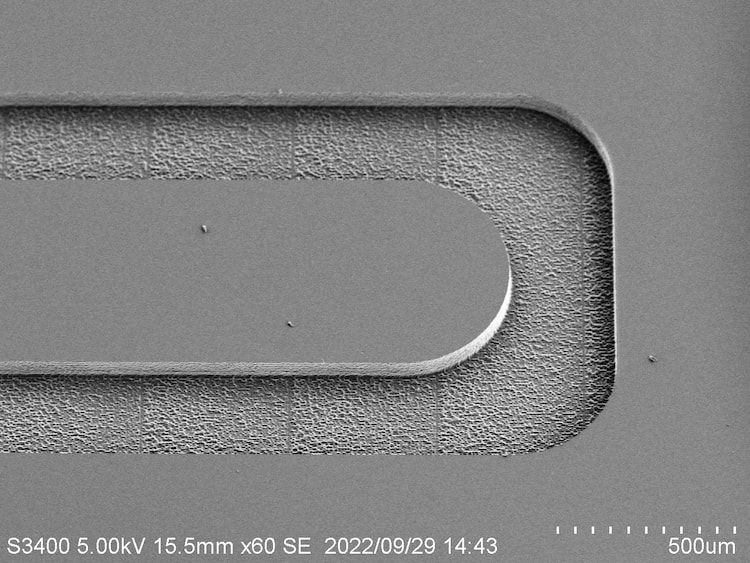

Wet etching

The wet etching process is mainly employed for metal wiring patterning and display slimming. Glass and ceramics can be etched by using an etching solutions such as aqua regia or hydrofluoric acid. Similar to dry etching, a mask pattern is pre-formed on the non-etched surfaces. However, since the etching reaction proceeds when the etchant comes into contact the surface to be processed, the cross-sectional shape of the etched areas is generally not rectangular but U-shaped with rounded corners. Compared to dry etching, etching rates are generally faster and device and running costs are lower.

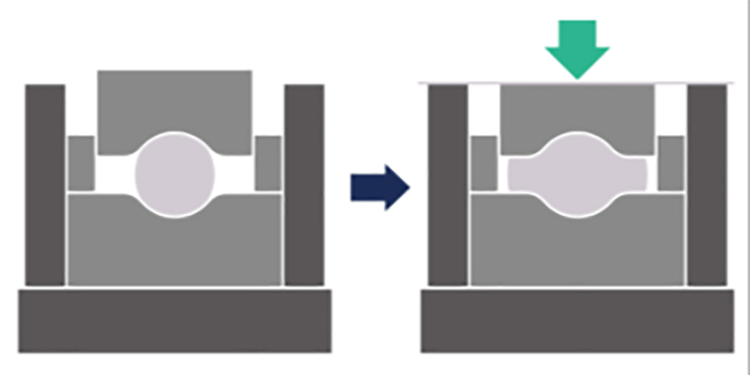

Molding

The molding process is mainly used in the production process of aspherical lenses. A metal mold is pre-made that transfers the structure of the aspherical shape to be formed. There are several molding methods, but for example, one method is to pour a glass material called a preform into the metal mold, heat it to soften it, and then press it. Although there is a cost for the initial metal mold production, it has a low defective quality and very high molding accuracy and suitable for mass production, so it is possible to keep the mass production cost down. However, due to the presence of the demolding process, this method is not suitable for forming highly vertical pillar-shaped structures with almost no taper.

Laser processing

By irradiating the material to be processed with high-energy-density laser light, it is possible to cut and form through-holes, etc., while melting and evaporating the material. In addition, combining the modification of material to be processed using ultrashort pulse lasers such as picosecond and femtosecond lasers with wet etching makes it possible to form hole completion and grooves quickly while minimizing thermal damage. Furthermore, since the area that has been modified by laser irradiation is removed by wet etching, it is also possible to perform processing to remove the damaged areas. However, the roughness of the finished surface is greater than with dry or wet etching, although not to the degree of cutting or blasting.

Grinding

By using a grinding machine, it is possible to form arbitrary curved surfaces and fine grooves on glass, making it easy to fabricate glass microfluidic channels. In both processing methods, no special devices or environment is required, so the initial cost can be kept low particularly, compared to other micro-processing processes. Yet, processing below the micron range is challenging, and the surface roughness of the processed area is much larger compared to dry etching or wet etching. As a consequence, additional surface finishing, such as polishing or wet etching, is required for products where light scattering may affect the product's performance.

Micro-processed glass products and their applications

AGC has been involved in the development and advancement of various glass micro-processing processes and has brought a variety of optical component-related products to society. Some of AGC's products and applications are described below.

Diffractive optical element (DOE)•EGlass diffuser

DOE is a device that utilizes light diffraction to split laser light spatially. AGC's DOE enables low 0th order transmission, wide FOV, and large number dot projection. Using glass, our DOE also a low coefficient of thermal expansion and has high reliably against thermal, humidity, and laser damage. AGC also sells glass diffusers. They are used in various fields such as sensing, AR/VR/MR, projectors, and lighting.

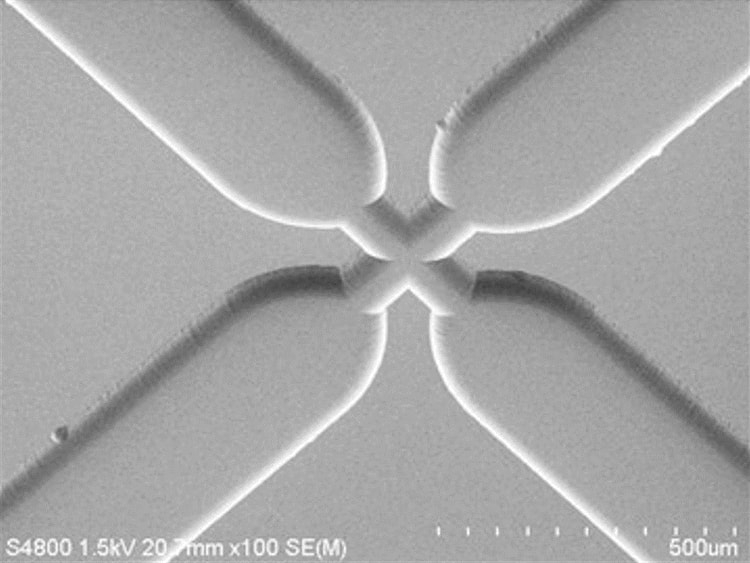

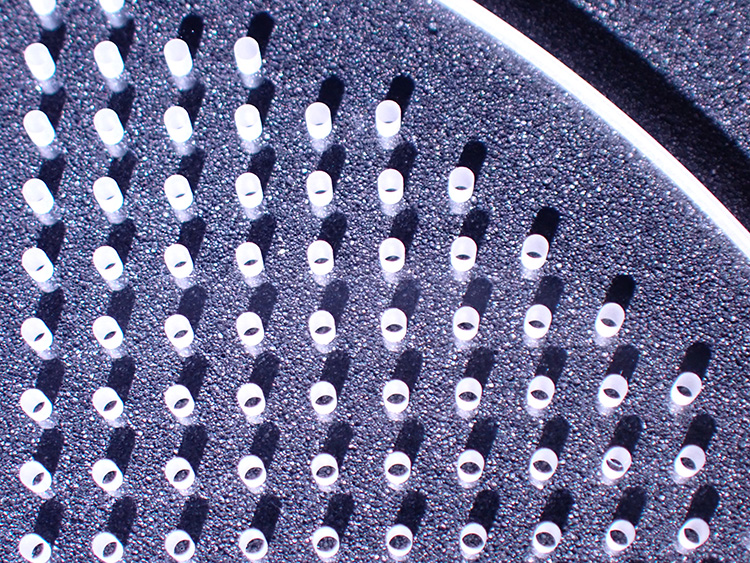

Through glass vias

AGC can make through vias in thin glass substrate by the patterns of customers' frequirements. AGC's TGV, which adopts glass as a base material, excels in flatness and shape stability, and also features the unique high insulation properties and low dielectric loss tangent of glass. Furthermore, TGV, an alkali-free glass with a thermal expansion coefficient similar to that of silicon, can be used in a variety of fields, beyond as a substrate for 3D mounting of semiconductor packages.

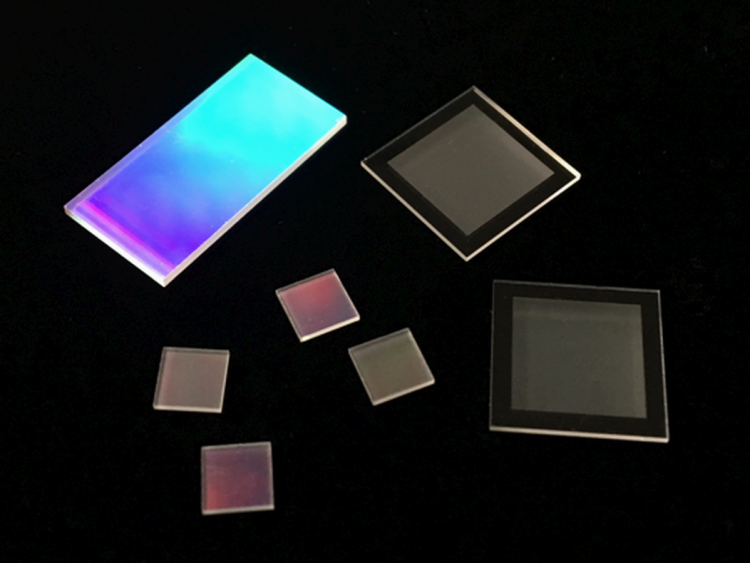

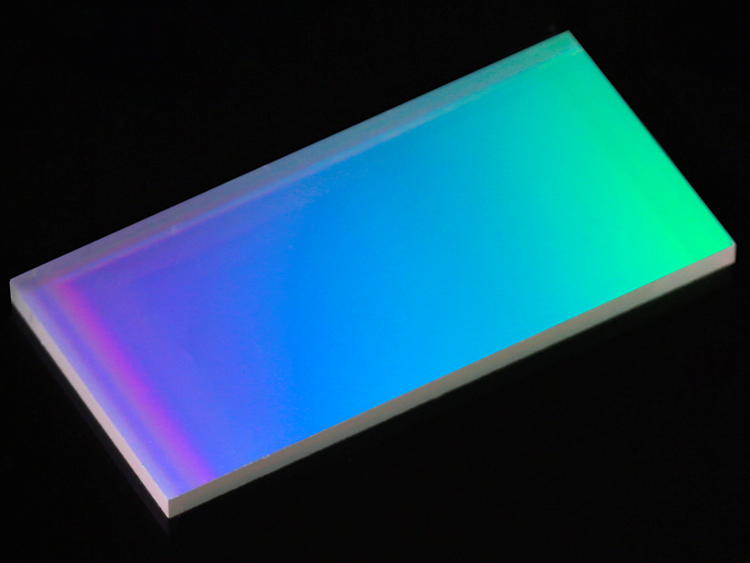

Transmission type diffraction grating

This is a type of device that imparts a fine periodic structure to transparent materials, enabling the diffraction of light or other waves. The incident light is diffracted at an angle corresponding to the wavelength of the light. AGC has its own unique optical design, micro-processing, and coating technologies. Its transmission type diffraction gratings, which apply these technologies, can be used in optical communications, LiDAR, and various other devices. We propose the optimal solutions to meet our customers' needs.

Aspherical glass molded lenses

It is a lens formed by a curved surface that is not spherical or flat. It is possible to correct aberrations with a single lens, and the focal length can also be shortened. AGC's aspherical lenses are made using precision glass molding technology and are superior to those made from polymers in terms of durability and can be used for a variety of purposes and in a variety of shapes. These lenses find applications in a wide range of fields, including digital cameras, in-vehicle cameras, optical communications, projectors, and sensing devices.

Materials used in micro-processed products

Various materials are being adopted in society for micro-processed products for optical applications. For example, quartz and borosilicate glass are examples of types of glass. Polymers such as poly-carbonate (PC), PMMA, COC and COP are also used. Other materials such as silicon (Si) and low-temperature co-fired ceramics (LTCC) may also be selected depending on the use case. The features of each material are briefly introduced below.

Glass•EQuartz glass

It is an all-round material with excellent pressure and thermal resistance, chemical durability, and gas barrier properties while maintaining light transparency in the visible light range. In particular, quartz glass is used mainly in high-end applications because it has a high transmittance over a wide wavelength range, even higher than that of ordinary glass. On the other hand, processing is not easy and requires know-how.

Polymers

We are able to keep product costs overwhelmingly low, since we can adopt highly mass-producible element formation processes such as embossing and injection molding. Therefore, compared to inorganic materials such as glass and silicon, polymers are lighter and can be given various additional functionality such as absorption and birefringence. At the same time, they are inferior to inorganic materials in terms of thermal stability and reliability.

Silicon (Si)

It is a material with excellent pressure and thermal resistance, chemical durability, and gas barrier properties However, because it does not allow light to pass through in the visible range, its uses are greatly limited while being slightly more expensive to process than other materials.

| Materials and various properties | Glass | Quartz glass | Polymers | Silicon (Si) |

|---|---|---|---|---|

| Transmittance (Visible range) |

Very high | Extremely high | High | Opaque |

| Autofluorescence (Visible range) |

Very small | Extremely small | Small | Extremely small |

| Pressure resistance (stiffness) |

Strong | Strong | Weaker than glass | Very strong |

| Thermal resistance | Strong | Very strong | Weak | Very strong |

| Gas barrier properties | Extremely high | Very high | High | Very high |

| Price | High | Very high | Low | Very high |

| Main processing methods |

|

|

|

|

AGC has been engaged in the processing and molding of various types of glass, including quartz glass, for many years. It has also built an exceptionally extensive track record while dedicating significant effort to the development of micro-processing and molding technologies. AGC will sincerely respond to your needs from prototyping to mass production, adjusting to each situation, especially if you are considering shapes that are difficult to achieve with traditional dry etching or molding, such as very deep grooves or holes relative to their width or diameter. Please do not hesitate to contact us.

Product inquiries & information requests