May 25, 2021Management

Alteryx Data Analysis Platform to be Deployed to AGC's Chemical Plants

- Accelerating the shift to Smart Factory with the use of intuitive tools -

Tokyo, May 25, 2021, - AGC (Headquarters: Tokyo; President: Yoshinori Hirai), a world-leading manufacturer of glass, chemicals, and high-tech materials, has announced that from May 2021 it will deploy Alteryx, a data analysis platform from Alteryx, Inc. to accelerate its shift toward Smart Factory. AGC expects deploying Alteryx to improve the efficiency of data analysis in its chemical manufacturing. In addition, by increasing talent who can wield two swords, that is, those who possess both knowledge of manufacturing operations and advanced data analysis skills, it aims to enhance the data utilization literacy of the organization as a whole. Furthermore, the system will be expanded to include production management and logistics operations, with data used to improve business process efficiency and strengthen competitiveness.

A scene of the system in use

A scene of the system in useOffers data processing through to validation of analysis results in one stop

Alteryx's workflow creation screen

Alteryx's workflow creation screenCombining tool icons for data analysis

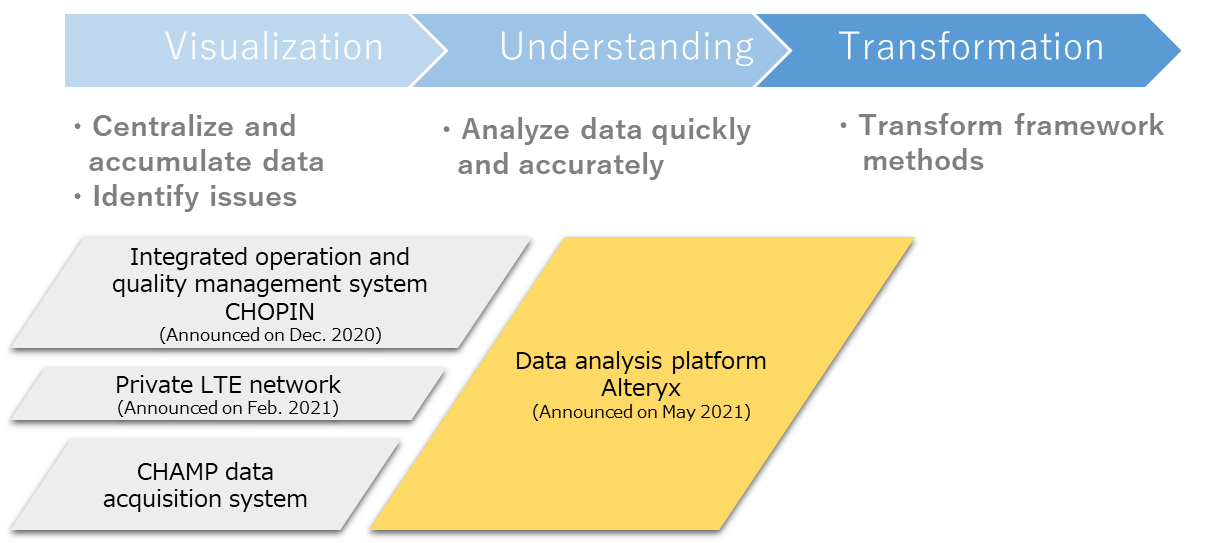

AGC is actively evolving its chemical plants to Smart Factories through the three steps of "Visualization," "Understanding," and "Transformation." As part of its efforts to "Visualization," AGC has introduced an integrated operation and quality management system called CHOPIN and a private LTE network to improve the efficiency of data collection. However, the data collected is currently analyzed based on the experience of each person in charge of the manufacturing process, using their own spreadsheets, etc., thus considerable time and effort are needed to integrate and analyze the data. Another issue is the development of human resources with expertise in both manufacturing operations and data science.

The system to be deployed this time is a data analysis platform featuring an intuitive graphical user interface and a rich set of tool icons that enable a variety of data processing. With Alteryx, it will be possible to capture and analyze data from each manufacturing process on a single platform, thus improving the efficiency of data integration and analysis work.

Alteryx can also automate the data processing process by simply connecting icons on the screen, making it possible for manufacturing staff even without programming knowledge to perform data analysis with a shallow learning curve. In this way, by adding the powerful skill of data analysis to manufacturing operations staff and fostering talent who can wield two swords, AGC will enhance the data utilization literacy of the organization as a whole.

■Approaches to converting AGC's chemical plants into smart factories

AGC is actively converting its chemical plants into Smart Factories through the three steps of "Visualization," "Understanding," and "Transformation." The deployment of the Alteryx data analysis platform is an initiative in the "Understanding" step.

Link: https://www.alteryx.com/ja/en/customer-center/agc-uses-alteryx-to-transform-the-business-and-maintain-pole-position

In 2020, AGC began using the Alteryx platform on a trial basis in the development of its CHAMP data collection and visualization system. As a result, AGC has significantly shortened the development period and cut system development costs by over 80%. CHAMP is an acronym for "CHemical plant Acquisition Method of Process data," a data storage platform for chemical plants developed by AGC. In addition to improving the efficiency and sophistication of data collection, AGC is also working on implementing data visualization functions to identify issues and resolve problems by "visualizing" data.

- MEDIA INQUIRIES

- Kazumi Tamaki, General Manager, Corporate Communications & Investor Relations Division

- Contact: Tomoko Nakao

- TEL: +81-3-3218-5603

- E-mail: info-pr@agc.com