AGC's DOE and diffuser products and technologies

In addition to the DOE and diffusers, AGC has produced optical element products for applications in optical pickup elements of CDs, DVDs and Blu-Rays and in optical communication modules so far. Such products include gratings, holographic elements, organic wave plates, polarizing holographic elements, liquid crystal active elements, and two- and three-wavelength compatible elements. Having experience in producing stable-quality products in volume, AGC can offer highly reliable glass solutions and organic/inorganic composite solutions with unique characteristics. We do this by making use of its optical simulation technology, glass micro-processing technology, and composition technology with liquid crystal materials.

Product overview and features

The features of diffractive optical elements such as gratings, holograms and DOE, and glass diffusers are also introduced here. The various projection patterns designed and developed by AGC can satisfy the needs of various customers in the field of LiDAR. In LiDAR, the light patterns emitted from the emitter vary depending on the target range to be scanned and the combination of scanning systems.

Elements such as DOE and glass diffusers can basically achieve the desired pattern when collimated beams are projected. By using them, one can improve light utilization efficiency, reduce the number of lens components, and lower the alignment cost. AGC has cultivated its technologies over many years, and in addition to its track record in mass production, we have experience in producing for example: DOE with low zeroth order diffracted beams (beams that pass through without being diffracted); diffusers with a wide angle of more than 100 degrees; and dot patterns in which laser beams are split into tens of thousands of dots. AGC can also make products that are tuned at various wavelengths from visible rays to near-infrared rays that are used in LiDAR systems and 3D sensing devices.

- One-stop service from design to mass production

- Inorganic materials that ensure high performance and reliability

- Advanced design and processing technology

One-stop service from design to mass production

AGC’s one-stop service covers everything from design to mass production and quality control. We will figure out optimal solutions to accommodate your desired profile and characteristics. In some cases, DOE using the diffraction phenomenon are suitable, and in other cases, glass diffusers using the refraction phenomenon are suitable, so we will propose appropriate products after receiving the requirement.

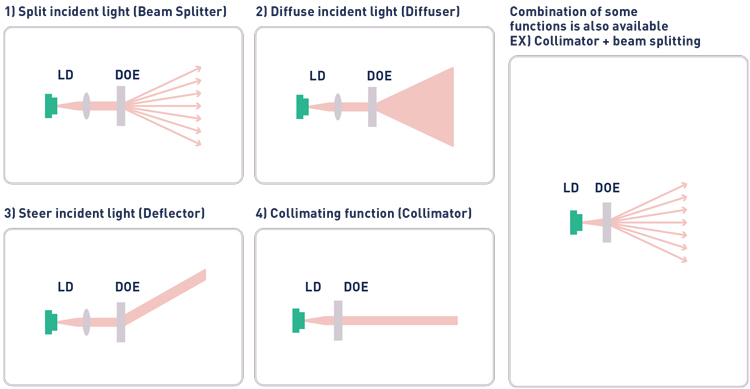

Light control by DOE. A DOE creates beam patterns by diffracting beams with a microstructure formed on its surface. DOE have a high degree of freedom in design and can be used in many ways, as shown in the figure.

Light control by DOE. A DOE creates beam patterns by diffracting beams with a microstructure formed on its surface. DOE have a high degree of freedom in design and can be used in many ways, as shown in the figure.

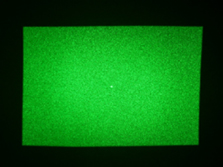

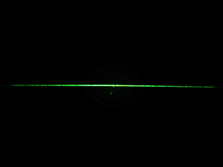

(Left) Pattern of about 1,000 evenly irradiated dots; (Center) Evenly diffused pattern; (Right) Line pattern

Inorganic materials that ensure high performance and reliability

AGC manufactures DOE and glass diffusers by micromachining inorganic materials, mainly glass materials. Optical elements handling laser beams need to be resistant to lasers. Being composed of inorganic materials, our products can display a high performance and reliability. They also have various advantages compared to polymer on glass (PoG), similar optical elements fabricated by the imprint technique using a resin or metal mold.

| Processing method |

Glass micro-processing |

|---|---|

| Prototype fabrication cost |

Since there is no need to make an imprint mold, we can reduce initial cost and lead time even when making multiple patterns. |

| Characteristics | The base material is processed directly without using a mold, which enables us to produce products having the exact advanced characteristics as we intended. |

| Reliability | Our products are less vulnerable to changes due to the environment (thermal expansion, swelling, solarization, etc.) and higher weather resistance than resin materials, reducing the risk of deterioration and de-lamination due to high temperature, high humidity and beam irradiation. |

Advanced design and processing technologies: Reduction in zeroth order diffracted beams, high efficiency, ultra-wide angle, pattern with tens of thousands of dots

AGC can design products that satisfy the requests of customers. So far, we have offered elements of various patterns: lines, dots, random patterns, diffused patterns, etc.

AGC has experience in producing elements with reduced low zeroth order diffracted beams which are passing through without being diffracted, diffusers with a wide angle of more than 100 degrees, and patterns in which laser beams are split into tens of thousands of dots. AGC can also make products tuned at various wavelengths, including visible rays and near-infrared rays that are used in LiDAR systems and 3D sensing devices. If you let us know the light diffusers with a wide angle of more than 100 degrees, and patterns in which laser beams are split into tens of thousands of dots. AGC can also make products tuned at various wavelengths, including visible rays and near-infrared rays that are used in LiDAR systems and 3D sensing devices. If you let us know the light source and your desired projection pattern, we will propose possible design specifications after careful consideration. Please feel free to contact us. In our typical process, we customize our products to suit customer’s requirement.

- LiDAR and AGC products

- AGC's DOE and diffuser products and technologies

- AGC’s glass ceramic package substrates for semiconductor lasers and technologies