Applications of High-Refractive-Index Glass Substrates

AGC’s high-refractive-index glass substrates

For AR/MR glasses (augmented reality or mixed reality), which are next-generation devices, AGC has been developing and proposing glass substrates for semiconductor packages and various optical electronic components with diversified characteristics. We also started developing substrates to be used in glass light guide plates several years ago, and have now succeeded in making glass substrates with a high refractive index and high transmittance for AR/MR glasses. Their mass-production system has also been established.

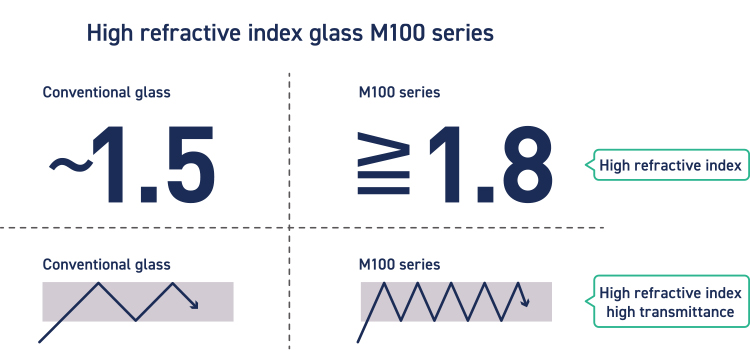

Glass substrates for AR/MR glasses must have a high refractive index to increase the viewing angle and high transmittance to show images clearly. In addition, advanced glass processing technology that enables a high level of flatness and surface smoothness, etc. is also required to make lenses propagate images precisely. The high-refractive and high-transmittance glass substrates that AGC has developed satisfy all of the required characteristics. The AGC Group mass-produces those products at its glass manufacturing sites and is pursuing a wide range of potential markets besides the AR/MR glass market, such as automotive applications.

Applications of high-refractive-index glass substrates

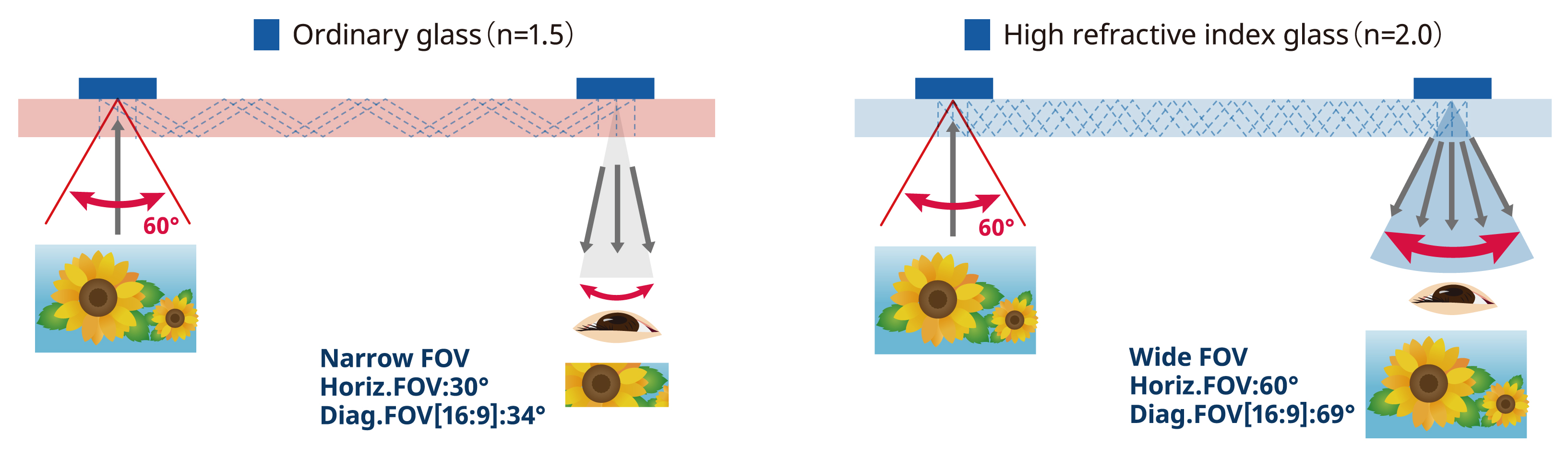

When the M100 series is used for the optical waveguide substrate of AR/MR glasses, it can take in images from a wider area and propagate them as clear and sharp images. As a result, it can produce a highly immersive AR/MR experience. The figure shows a typical optical system of an optical waveguide substrate of diffraction element-type AR/MR glasses. Images output from a microdisplay, such as a liquid crystal display (LCD) liquid crystal on silicon (LCOS), micro LED and OLED are condensed by a lens and enter the waveguide substrate. An in-coupling grating and an out-coupling grating are formed on the waveguide substrate, and an image incident from the display side is diffracted by the in-coupling grating and travels through the waveguide substrate in the in-plane direction. The image that is totally reflected and guided to the front of the eyes of the person who wears the glasses changes its propagating direction to the outside of the waveguide substrate because of the out-coupling grating and reaches the eyes of the person. When an image with a wide field of view is transmitted with ordinary glass, the image enters the glass at a high incident angle because the critical angle of light is large in ordinary glasses, and some parts of the image are lost while it is propagating. However, by increasing the refractive rate of glass, the same size of image can be propagated without losing any parts. The angle of view of an output image is called the viewing angle. High refractive index glass can output an image with a wider viewing angle than ordinary glass; that is, it can show a more realistic image. In addition to the viewing angle, advanced glass processing technologies that enable very flat and smooth surfaces are also important in order not to disturb the propagation of images that travel while being reflected repeatedly.

- Optical Glass

- Lens Applications

- AGC’s Glass Lens Business and Processing Technology

- Example Product Specifications for Aspherical Glass Mold Lenses

- Applications of High-Refractive-Index Glass Substrates

- High Refractive Index Glass Substrate M 100 Series