Glass is not just a transparent solid material.

Glass is a very homogeneous material among many solid materials and has isotropic properties due to its random structure.

In addition, being an inorganic material, it has high durability, which makes it different from other transparent materials.

The characteristics can be continuously tuned by designing its composition, in other words, by changing the ratio of various elements.

Optical glass is a glass material developed by taking full advantage of these characteristics and is used in various optical components including lenses.

Structure and Principle of Optical Glass

Glass has a long history and was already being used by mankind about 5,000 years ago. At first, it was valued as jewelry because it has clear transparency, develops a vivid color, and shines when exposed to light. The brightness and color of glass are due to the characteristics of glass, such as its transparency and refractive index, and optical glass makes use of these characteristics. Transparency and refractive index are two important parameters of optical glass. They will be explained later.

At present, an understanding of the physical properties of glass has been deepened, and in addition to the indices of optical properties, solubility at high temperatures and formability when softened are also taken into account when designing glass. For example, various glass products around us are mainly made from silica sand, which is mainly composed of silica (SiO2). Silica sand melts at a very high temperature (over 1,700°C). So, soda ash (Na2CO3) is usually added to lower the melting point and lime (CaO) is added to the ingredients to make the glass insoluble in water. This glass is called soda-lime glass and is often used in windows. In this way, we can make glass having various characteristics by adding other elements to the predominant ingredient, silica.

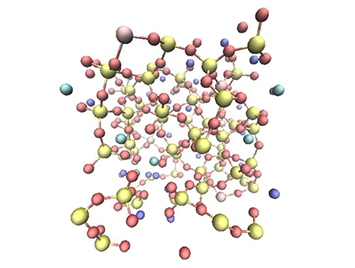

Glass network structure at the atomic level

Silica has a strong covalent bond of Si-O, but when additives such as Na are added, the covalent bond breaks and the properties change. Atoms in the network structure are arranged randomly with no regularity like a crystal, and such a structure is called amorphous. For this reason, whatever direction light goes in glass, it propagates through homogeneous crystal fields, and such high homogeneity is one of the important characteristics of optical glass.

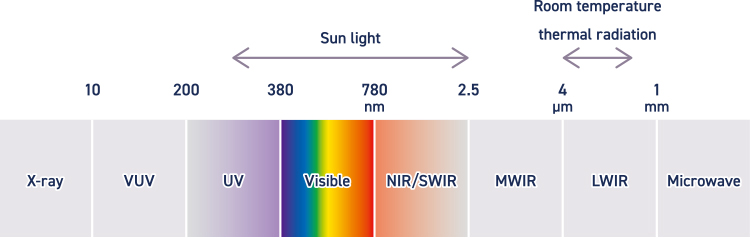

1. Transparency

When you look at some scenery through glass, you can see things on the other side clearly. This is because the glass transmits the visible light that has passed through an object. Visible light is a form of electromagnetic wave with a wavelength normally in the range of 380 nm to 780 nm that can be recognized by the human eye. Various wavelengths are used in the optical field. For example, ultraviolet light is used for sterilization, near-infrared light is used for sensing and optical communication, and far-infrared light is used for thermal cameras and night vision cameras. When we say optical glass is transparent, that means the glass has high transmittance in the wavelength range of the relevant application.

Light is a form of electromagnetic wave, and each wave has a wavelength (the length of a period of an electromagnetic wave). Human eyes can generally sense only light in the wavelength range called visible light rays, but optical glass and its processed products handle a wide range of light rays (electromagnetic radiation), including X-rays and microwaves, depending on the application.

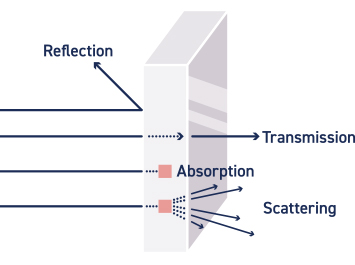

The transparency of glass depends on the composition of the element used in the glass. In addition to that, it is important to control absorption and the scattering of light to achieve high transparency. For example, ordinary window glass contains iron in its composition, so it is slightly green even though it is transparent. This is due to the absorption of iron ions in the glass. Optical glass is designed to reduce such absorption by impurities. Even micron-size foreign matters inside the glass scatter light rays there, reducing the transparency of the glass. Some types of optical glass actively utilize absorption and scattering caused by additives and impurities.

Conceptual image of light rays passing through glass.

Light entering glass is first partially reflected on the surface and the rest enters the interior. While it is propagating through the glass, if additives that absorb light are present in the glass, part of the light is absorbed, and if additives or imprities that scatter light are present, the light is scattered to random directions. When the light reaches the opposite side, part of the light is reflected again, and the remaining light comes out of the glass as transmitted light.

2. Refractive index

Refractive index is one of the most basic indices of optical properties of glass, along with transparency. The refractive index of glass is determined by its composition. As its name implies, it influences the refractive angle of the light. In addition to that, reflectance and transmittance of the glass are also dependent on the refractive index. The refractive index is the most fundamental characteristic that indicates the interaction between light and the glass and is the basis of the optical behavior of glass.

The most familiar application of glass substrates with different refractive indices is the camera lens unit. Recently, optical waveguide substrates for AR/MR glasses have also been commercialized using the high optical confinement properties of high-refractive-index glass.

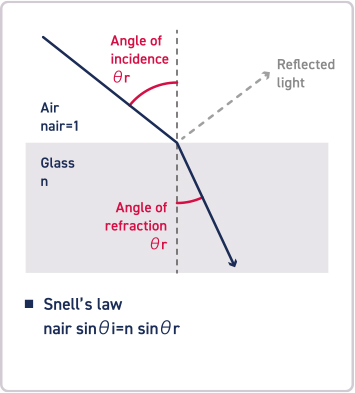

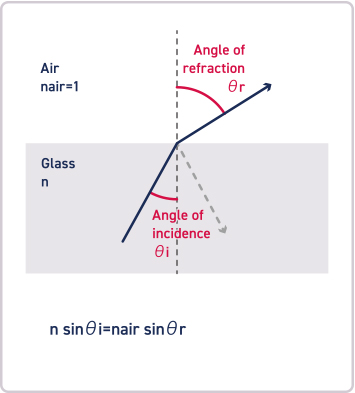

■ Refraction condition (air to glass)

■ Refraction condition (glass to air)

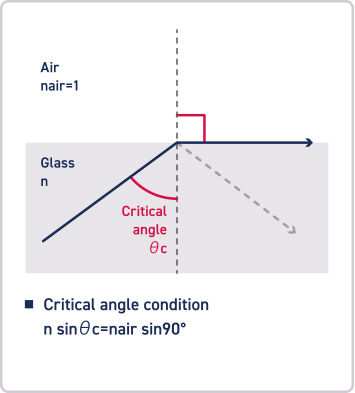

■ Total reflection condition

Refraction and total reflection of light traveling between different media (e.g., air and glass).

When a light ray travels from the air to the inside of glass or from the inside of glass to the air, it does not go straight but changes its direction of travel, and this phenomenon is called refraction. The refractive index of a material is expressed as the ratio of the change in angle that happens when a light ray enters the material from a vacuum; the higher the refractive index, the greater the angular change. When a light ray travels from air with a low refractive index to glass with a high refractive index, the angle of the ray going out of the interface (refraction angle) is smaller than the angle of the ray coming into the interface (incidence angle). On the other hand, when a light ray travels from glass with a high refractive index into air with a low refractive index, the refraction angle becomes larger than the incidence angle. If the incidence angle of a light ray gets larger when it travels to air with a low refractive index from glass with a high refractive index, the refraction angle reaches 90°; that is, the light ray is totally reflected without entering the air. The angle at which this total reflection occurs is called the critical angle. The higher the refractive index of the glass, the smaller the critical angle and the wider the angle range of total reflection. That means, the glass has a strong light-confinement effect.

Types of Optical Glass

Plenty of types of optical glass are designed by optimizing the transparency and refractive index according to applications and are commercially available. When choosing a type of optical glass, we need to take into account not only the material of the glass but also the processing method suited to the application.

Glass for Press Molding

Press molding is mainly used for mass-producing aspherical glass mold lenses. The lenses produced by this method are called glass mold lenses, because in this method, glass material (preform) is placed in a precision-processed metal mold, heated so it is softened, and then pressed. Since glass material for this method needs to be heated and pressed into shapes, optical glass with a low glass transition point (Tg) and a low softening point (Ts) has been used. The refractive index and Abbe number are also important indices to measure the optical properties of optical glass. A lens unit consists of multiple lenses and achieves advanced performance by combining not only the curvature of each lens but also the refractive index and Abbe number of the glass material.

Lenses made by press molding

Lenses made by press molding

Glass for Reheat Press

Low expansion borosilicate glass (CTE: 33) that has an excellent heat resistance and durability is mainly used as glass material for a reheat press. This method is similar to the precision mold pressing in that preforms are pressed into shape. However, in this method, the preforms are heated to above the softening point in forming, which reduces restrictions in processing and enables them to be molded into more complex shapes.

Lenses made by reheat press

Lenses made by reheat press

Chalcogenide Glass

This is a glass material developed for press molding. It transmits far-infrared rays. Materials such as silicon and germanium can also transmit far-infrared rays, but this glass is characterized by its ability to be mass-produced with press molding.

Chalcogenide glass lens made by press molding

Chalcogenide glass lens made by press molding

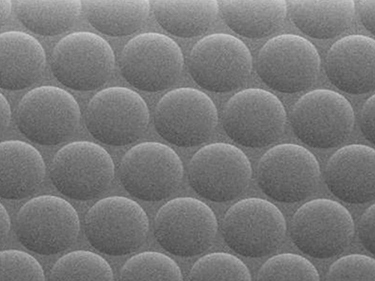

Glass Micro-Processing

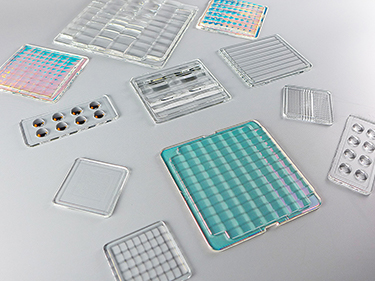

Optical glass substrates are etched and coated to become glass elements that function as lenses. Since an optical functional surface is formed by using micro-processing technology, it is suitable for the manufacturing of fine structures such as microlens arrays.

Example of glass micro-processing

Example of glass micro-processing

High-Refractive-Index Glass Substrates

AGC's high-refractive-index glass substrates are glass materials developed for AR/MR glasses and they can be used for other applications. Unlike glass materials for lenses, they are processed into thin substrates such as wafers before being supplied. In AR/MR glasses, this type of glass has an optical waveguide function to make images from a projection device, such as a microdisplay, propagate in the glass substrate. In order to enhance the light-confinement effect inside the glass (reduce the critical angle), they need to have a high refractive index and high transmittance, and be very flat. Furthermore, because they are used for wearable devices, their specific gravity should be reduced (lightweight).

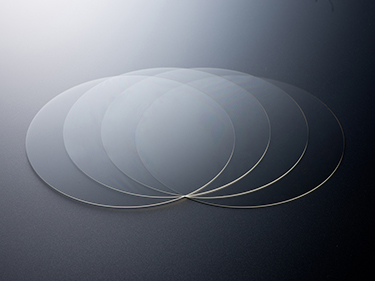

High-Refractive-Index Glass Substrates

High-Refractive-Index Glass Substrates

Glass for IR cut filters

This is a glass material that has high transmittance in the visible light range and absorption in the range of near-infrared light. It is also called blue glass because it is bluish. It is set in front of CMOS and CCD sensors and is used to match the visual sensitivity of the sensor with that of a human. When actually mounting it in a camera module, optical multilayer films are also used together with it to enhance its performance.

Photograph of glass substrates for IR cut filters

Photograph of glass substrates for IR cut filters(The interference color is produced on substrates coated with an optical multilayer film.)

Characteristics of Optical Glass

There are approximately 50 materials that are used in the optical glass designing, and the main materials are oxides such as silica (SiO2), boron oxide (B2O3), and alumina (Al2O3). The composition is examined at the designing stage so as to develop glass suited to the application and processing method. There are countless combinations of raw materials for producing glass, but the performance of each material combination can be predicted to some extent, such as refractive index, Abbe number, coefficient of thermal expansion, glass transition point, softening point, and weather resistance.

In fact, some combinations turn out not to be exactly as expected, and we also have to take into account the processability. This is a challenge but is interesting. Particularly, we pay attention to the following points in designing and developing optical glass products.

| Refractive index | The relationship between refractive index (n), speed of light traveling in the glass (v) and speed in a vacuum (c) is expressed as v = c/n. Refractive index is the most basic index of the optical properties of glass. It determines the critical angle at which light rays are contained in the glass, and also influences the reflectance. The refractive index varies with the wavelength of light, but the helium d-line wavelength (587.6 nm) is commonly used as a reference to measure the refractive index nd. |

| Abbe number | The refractive index of glass varies slightly with the wavelength of light, and the degree of fluctuation in refractive index due to wavelength variation is called dispersion. The Abbe number is used to measure the degree of dispersion, and (nd -1)/(nF-nC) is mainly used (F: 486.1 nm, C: 656.3 nm). The larger the Abbe number, the smaller the dispersion. |

| Glass transition point (Tg) | The transition of a substance from a supercooled liquid state to a glassy state is called the "glass transition" phenomenon, and the temperature at which the glass transition occurs is called the glass transition temperature (or glass transition point) and is expressed by Tg. At this point, glass viscosity is approximately 1013 to 1014 dPa・s, and it is used as a reference when determining the temperature for annealing. |

| Softening point (Ts) | The temperature at which the viscosity of glass reaches 107.6 dPa・s is called the softening point; above it the glass starts to soften and deform significantly. When the temperature of glass is above that point, it is easy to form it from an optical point of view. |

| Specific gravity | Specific gravity is the value obtained by dividing the mass of the material per unit volume by the value of water at 4°C, and varies depending on the composition of the glass. For example, the specific gravity of soda lime glass is approximately 2.5, while that of silica glass is about 2.2. If there is a need for lightweight optical glass in some applications, the density of the glass should be reduced as much as possible. |

| Coefficient of thermal expansion (CTE) | Coefficient of thermal expansion is the longitudinal and volume expansion of a material per Celsius degree. The CTE of glass is generally measured in the temperature range of 20 to 300°C. General optical glass has a CTE of about 1 to 100 x 10-7/°C. |

| Surface roughness and surface accuracy | Surface roughness and surface accuracy are one of measures of profile errors relative to the ideal surface texture. Surface roughness represents the degree of microscopic unevenness with respect to the ideal surface, and surface accuracy represents the maximum error with respect to the ideal surface and is expressed in wavelength units. If the deviation from the ideal surface becomes large, effects such as light scattering and wavefront aberration will occur, so it is necessary to keep the error to a level sufficiently smaller than the wavelength. |

| Weather resistance | Weather resistance indicates to what degree the material can withstand forces or substances (deformation, discoloration, deterioration, etc.) when exposed to sunlight, ultraviolet rays and rain for a long period of time. Various testing methods are available depending on the application and operating environment. Since glass is an inorganic material, it tends to exhibit higher weather resistance than organic materials such as resins. |

Applications 1: Lenses

Applicable Products

Lenses are used in various applications such as imaging devices like cameras and projectors, optical communications, automotive cameras, headlamps, and sensing modules. A lens condenses light on a convex surface and diverges light on a concave surface. In addition to the curvature of the lens, the refractive index and dispersion characteristics of optical glass also determine the lens performance. The size, materials, required shape and accuracy of glass differ depending on the application and the place where it is used. AGC handles various optical glass lens products, and they are used in a wide range of fields.

Camera (SLR cameras, mirrorless cameras, video cameras, smartphones)

Camera (SLR cameras, mirrorless cameras, video cameras, smartphones)

Projectors

Projectors

Automotive cameras, headlamps, night vision

Automotive cameras, headlamps, night vision

Sensing, LiDAR

Sensing, LiDAR

Applications 2: Optical Glass Waveguides

Applicable Products

Next-generation wearable display devices called AR/MR glasses have attracted much attention in recent years. AR and MR stand for augmented reality and mixed reality, respectively, and refer to displays that are like a pair of glasses and that allow people who are wearing them to see virtual images superimposed on the real world. These hands-free AR/MR glasses are showing promise as next-generation devices to replace smartphones.

The AR/MR technology is expected to make our lives more convenient and affluent. The video introduces AGC's solutions required for AR/MR.

In such a virtual reality display, optical waveguide substrates are used inside the glasses to guide the image output from a microdisplay to the eyes of the person wearing the glasses.

Several types of optical waveguide substrates for AR/MR glasses have been proposed as shown in the table. Each type has advantages and disadvantages, but the diffraction grating type has the advantage of making AR/MR glasses thinner and lighter.

| Type | Schematic diagram of light extraction section | Principle | Advantage | Disadvantage |

|---|---|---|---|---|

| Reflecting mirror |  |

Light is reflected by half mirrors. In some configurations, half mirrors are arranged in the waveguide substrate. |

The configuration is simple and causes little image irregularity. High color reproducibility. |

Difficult to make it thin and compact. Tends to get thicker in order to widen the viewing angle. It is necessary to install several mirrors in order to expand the eye box. |

| Volume hologram |  |

Light is reflected at a predetermined angle by volume holograms. | It is easy to make it thin and make it into a wearable device like glasses. Light extraction part is inconspicuous. |

Advanced design technology is required. Since the hologram material is sandwiched, the number of glass sheets used increases. Compared with other types, it is difficult to produce in volume. It is more difficult to control the color reproducibility than the mirror type. |

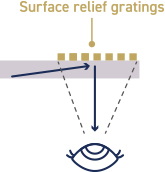

| Diffraction grating |  |

Light is diffracted at a predetermined angle by diffraction gratings formed on the surface of the waveguide substrate. | It is easy to make it thin and make it into a wearable device like glasses. This type has a high degree of design freedom and well suited to mass-productivity. |

Advanced design technology is required. It is more difficult to control the color reproducibility than the mirror type. |