Lens Applications

Aspherical glass mold lenses

An aspherical lens is one with a curved surface that is neither spherical nor planar, and that has several different radii of curvature on one surface. A lens unit such as a camera lens is made by combining multiple lenses. When a spherical lens is used, the light entering the periphery area of the lens meets at points closer to the lens; that is, the light beams passing through the lens converge at different points, making the image blurred. This is called aberration, and to correct it, it is necessary to combine several spherical lenses; as the number of lenses used increases, the lens unit becomes larger and the cost increases. On the other hand, an aspherical lens can correct the aberration only with a single lens, and is also able to reduce the focal length. This lens enables small-size lightweight lens units and reduces cost. In addition, by using glass as the material of the lens, we can make use of its excellent characteristics including its optical properties, weather resistance, and stable temperature characteristics. These characteristics enable us to develop a variety of products and widen the range of applications.

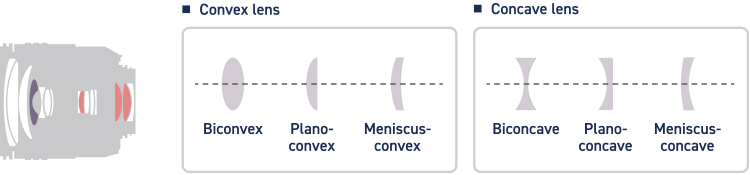

A camera lens unit is designed by combining several lenses.

A camera lens unit is designed by combining several lenses.

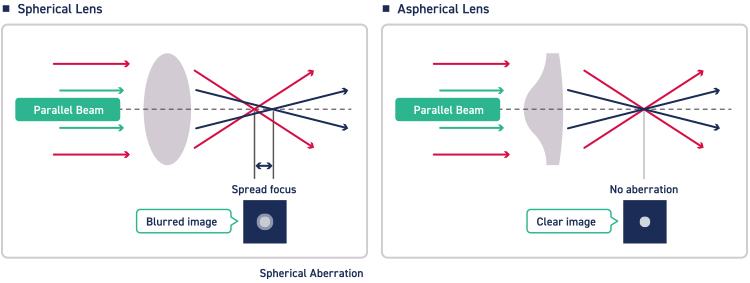

When a spherical lens is used, the image becomes blurred due to aberrations. By introducing an aspherical lens, rays passing through the center of the lens and those passing through the periphery area converge at a single focal point.

When a spherical lens is used, the image becomes blurred due to aberrations. By introducing an aspherical lens, rays passing through the center of the lens and those passing through the periphery area converge at a single focal point.Aberration refers to: "the influence of light rays passing through points other than the center (optical axis)." For example, when light rays entering the center of the lens and those entering the edge of the lens fail to meet at a single point, the image goes out of focus. This phenomenon is called aberration (spherical aberration). There are many types of aberration—astigmatism, spherical aberration, field curvature, distortion, coma, chromatic aberration, etc.

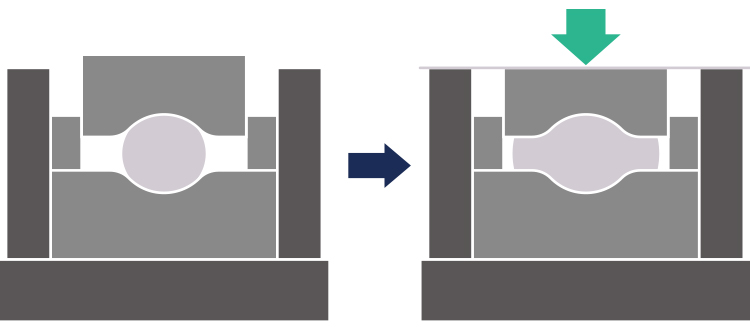

Aspherical glass lenses are manufactured in a different way than spherical lenses. Spherical lenses are mainly made by polishing, but it is difficult to form aspherical surfaces this way. Therefore, instead of polishing, glass molding technology, which is highly suited to mass-production, is used to make aspherical lenses. In this method, glass material (preform) is placed in an aspherical metal mold, heated to soften it, and then pressed. There are several types of preforms, including polished balls, fine gobs, and polished preforms, but each has its own characteristics. We use appropriate preforms according to the application.

To mass-produce glass mold lenses using preforms, what we need to do first is to produce metal molds. The mold material is processed, and the surface to be used for the molding is formed into aspherical shape with good reproducibility. The next process is mold pressing. To manufacture lens parts of imaging systems, components that require extremely high optical properties, the isothermal pressing method is used. In this method, the glass and metal mold are kept at the same temperature during molding. On the other hand, for lenses that do not require that precise optical properties, non-isothermal press molding, in which high-temperature glass is molded in a mold that is slightly lower temperature than the glass, is used.

In the isothermal pressing method, the temperature of the mold is gradually raised until it becomes equal to the temperature of the glass, and then, the glass is press-molded. Next, it is cooled down as it is and removed from the mold as a product. Temperature control is very important and the temperature is strictly controlled so that no stress remains inside the lens. The process is also called annealing. The external shape of the lens that has been taken out of the mold is processed, and if required by the specification, coated with an antireflection film to become a product.

Important key technologies for the press molding are technology to make precise metal molds and processing technology. The conditions must be optimized for each product in accordance with the composition, specification and size of the glass to be used for the lens. When producing lens products in volume, it is necessary to carefully produce several million lenses or more one by one as they affect the characteristics of cameras, each of which is expensive.

Although it is just the manufacturing of lenses, there are many things to consider, including which materials and production method we should use, and how to control quality throughout the stages from the process development to mass-production. That is, it takes a long time to develop. Even so, with the technology and know-how we have accumulated over many years, AGC is able to shorten the development period and provide products that meet various customer needs.

Fig. Preforms are pressed in a metal mold and formed into the shape of a lens.

Fig. Preforms are pressed in a metal mold and formed into the shape of a lens.