Addressing climate

change

The use of renewable energy is indispensable to achieving carbon neutrality. As Japan lacks land suitable for mega-solar power plant construction, what is the best way to secure necessary amounts of electricity? Let’s hear the thoughts of an employee involved in the marketing of “SUNJOULE™” (hereinafter, “SUNJOULE”), a photovoltaic glass integrated into the building envelope and building materials that was developed with the idea of turning urban buildings into solar power plants.

Adding power generation functionality to the glass elements of buildings. Facilitating local power generation for local consumption

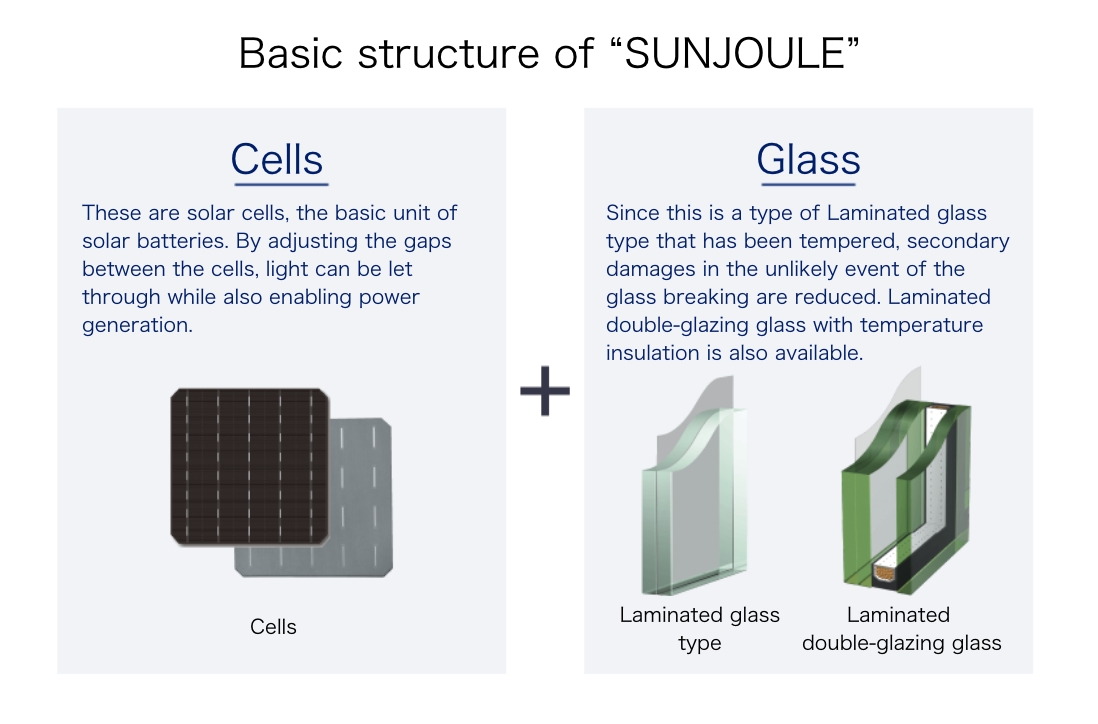

AGC's “SUNJOULE,” photovoltaic glass integrated into the building envelope and building materials, consists of a solar cell sealed between two pieces of architectural glass to create a type of laminated glass with photovoltaic properties. By arranging high-transmittance glass on the surface that receives the light (the outside), power generation efficiency has been improved, while high durability as a building material has been realized through proven laminated glass production technology. You can choose between monofacial solar cell that generate electricity by receiving sunlight from one side, for things like curtain walls and skylights, and bi-facial solar cell that receive light from both sides, for things like fences and handrails.

Multi-layered structures involving “SUNJOULE” can also add functions other than power generation. For example, if combined with Low-E glass (glass coated with a Low-E film that reflects infrared rays while letting light through), heat shielding and heat insulation can be improved.

Marketing Manager, Smart Glass Team, Market Development Group, Japan General Division, Architectural Glass Asia Pacific Company

Development started to make the window itself have a power generation function

AGC's Smart Glass Team deals with advanced architectural glass products related to electricity. These products include “smart tinting glass” under development and signage glass with integrated LEDs, but in recent years we have been focusing on “SUNJOULE,” photovoltaic glass integrated into the building envelope and building materials.

The development of “SUNJOULE” began in 1999. The first product, SUNJOULE SQUARE, was launched in 2001. Solar power generation is expected to be one of the pillars of renewable energy, but as Japan has so many mountainous areas, there is limited flat land suitable where solar panels can be installed. This inspired the idea that it would be good if the glass elements of buildings could generate electricity.

Solar cells installed on buildings are generally placed on the roof. However, the roof of a building is not very big. So we thought that if the walls and windows themselves could have a power generation functionality, it would help solve energy problems in urban areas.

After that, we continued to develop new products in response to market needs, and in 2015, we launched “SUNJOULE SUDARE,” which can be used as windows to make the most of the view. From 2021, we started selling the “SunEwat” series, which has inconspicuous cells and excellent design. Currently, we're also developing products that can be used to renovate existing buildings and products that do not lose power generation efficiency even when placed vertically.

Carefully conveying the high added value of “SUNJOULE”

The customers we offer “SUNJOULE” to are in various industries, including builder clients, designers, and general contractors. Since “Building-Integrated Photovoltaics(BIPV)” is unfamiliar to many customers, it took time to correctly convey and have them understand the value of the product.

“SUNJOULE” combines the functions of “architectural glass” and “solar power generation,” but the area of the power generation cell is smaller than that of regular solar panels because it has the feature of letting light through. As such, if you simply look at the cost-effectiveness of the amount of power generated, most would not opt for it. In light of this, we explained to customers that it also has value as architectural glass and that by enabling power generation in the glass elements of a building, it becomes possible to generate power in parts previously unused. We carefully convey that, comparing it to mega solar power, “there is no need to purchase land for solar power generation or to draw power grids from mega solar generators to the areas where electricity is needed” and that “environmental measures can made visible (thus contributing to raised awareness).”

In order to make this standard for “SUNJOULE” product descriptions, we revised presentation materials and catalogs. We created opportunities for people to pay attention to social value in addition to economic value. Nowadays, more and more customers see the value of “SUNJOULE” from a macro perspective when considering whether to use it or not.

Photo courtesy of JR East Design Corporation

Constructed in 2019. The area covered is about 500 square meters. The rated output is about 44 kW. The main product type is “SUNJOULE SQUARE” on the platform roofs, while “SUNJOULE SUDARE” is also used for some parts of the concourse windows. The station’s concept is to be an environmentally friendly and disaster-resistant “eco-station,” and they picked “SUNJOULE” because it matched the concept so well. By installing storage batteries and other equipment, “SUNJOULE” can also be used as an emergency power source in the event of a disaster.

Constructed in 2018. The area covered is about 240 square meters. The rated output is approximately 13.4 kW. The product type is “SUNJOULE SUDARE” installed in curtain walls. Since the building aimed for ZEB (net zero energy building) certification as promoted by the government, “SUNJOULE” was picked for providing both energy generation and energy conservation when combined with low-E energy-saving glass. Partly thanks to the contributions of “SUNJOULE,” the entire building has achieved the highest rank of “ZEB” recognized by the Ministry of the Environment.

Supporting companies to promote carbon neutrality

By selling “SUNJOULE,” it feels like we are contributing to individual companies’ carbon neutrality, albeit in a small way. In recent years, inquiries from corporate departments of sustainability promotion, carbon neutrality promotion, and so forth have increased significantly. Many in charge of such departments want to “educate people inside and outside the company that environmental measures are being taken in an easy-to-understand manner.”

“SUNJOULE” is a product that can meet the needs and expectations of such departments in that it can generate electricity through glass, which is familiar to us in our daily lives (windows, eaves, roof glass, handrail glass, etc.). The number of inquiries is increasing year by year, and I feel that there exists a strong market need for this product as society aims to achieve carbon neutrality.

Another strength of AGC is that it has a diverse product lineup that meets customer needs, including not only “SUNJOULE” but also “Sunbalance” (Low-E double-glazing glass) and “ATTOCH” (Low-E glass that can be retrofitted on construction sites). Including the high-quality construction technologies of Group companies, we are contributing to society through synergy.

Wanting to generate power equivalent to mega solar power from window glass

In addition to “SUNJOULE,” AGC has other types of architectural glass related to electricity. In the future, we expect that the number of high-performance products that require electricity will increase even more.

For example, we have a product called “smart tinting glass” that is currently under development. “smart tinting glass” is a product that uses electricity to change the color of the window glass from transparent to dark. By making it darker, heat shielding performance is improved, thus reducing the load of heating and cooling and reducing environmental impact.

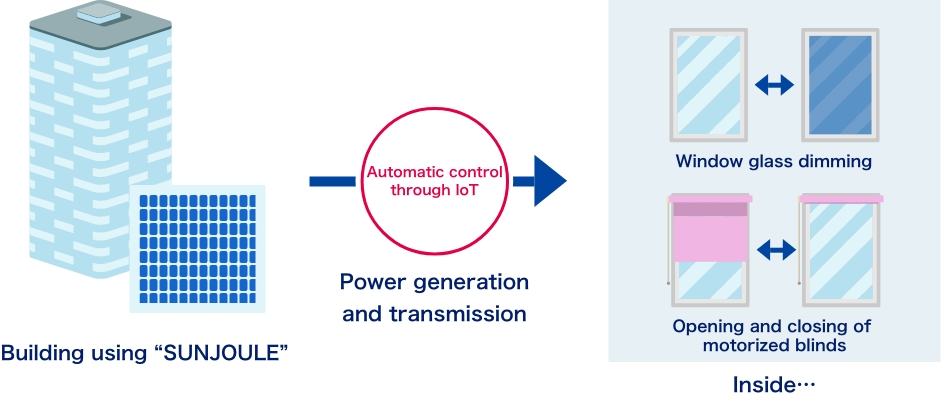

In the future, it will be possible to use the electricity generated by “SUNJOULE” to supply electricity to the “smart tinting glass” and other glass products and electric blinds. If “SUNJOULE” is used as a power source and “smart tinting glass” and electric blinds are converted to IoT, the color of the dimming can be changed and the blinds can be opened and closed according to the weather, thus allowing for optimal operation. We feel that this has the potential to transform the indoors into a comfortable and sustainable space.

Fossil fuels are used in glass manufacturing processes, but in the future, we will improve combustion efficiency so that glass manufacturing methods emit less CO2. We are also working on glass recycling, hoping to contribute to a more sustainable society through these activities.

By further reducing the heating and cooling load of houses and buildings through the spread of Low-E double-glazing glass and ATTOCH, and by expanding the scale of “SUNJOULE” use, we would like to contribute to solving energy problems and creating a future where window glass can generate power equivalent to that from mega solar power generation.