Building an

info-oriented,

IoT-society

Semiconductors are used in smartphones, televisions, and other electronic devices that are all around us. AGC provides photomask blanks for EUV lithography and CMP slurries, important components in the semiconductor manufacturing process. We interviewed a sales representative to find out how the company continues to meet the difficult demands of leading-edge semiconductor manufacturers.

Supporting the evolution of semiconductors with advanced electronic component technology

Semiconductors are manufactured by forming circuits using exposure technology, and AGC's photomask blanks for EUV lithography and CMP slurries are both used in the formation of these circuits. Photomask blanks for EUV lithography are essential components in exposure technology using EUV wavelength (13.5nm), which is indispensable for the latest semiconductor miniaturization, and they require outstanding material properties, ultra-high flatness, and ultra-low defect process technology.

CMP slurries are polishing slurries used in a process called chemical mechanical polishing (CMP), which is a technology necessary to accurately form circuits, and they require material properties and high-dimensional quality control. Both of these materials are sold to semiconductor device manufacturers and are critical for manufacturing the semiconductors that drive all the electrical products that abound in the world.

Photomask blanks for EUV exposure

CMP slurries

Manager, Sales Group, Lithography Department/Thermal Department, Advanced Materials Division, Electronic Materials General Division, Electronics Company

Taking advantage of AGC's manufacturing methods to foray into the field of high-quality semiconductors

AGC succeeded in developing a synthetic quartz process in the 1980s and has since built up a track record in the semiconductor field. Its main business initially was the manufacture and sale of photomasks for semiconductor exposure but, by taking advantage of the features of its manufacturing methods, AGC moved into fields such as lenses for semiconductor exposure equipment requiring higher quality. Furthermore, we have built stronger relationships with customers in the semiconductor sector by integrating such businesses as SiC components for semiconductor equipment previously handled by the Ceramics Business, CMP slurries for semiconductors handled by the Chemicals Business, and more recently photomask blanks for EUV lithography handled by the Technology General Division.

Since joining the company in 2011, I have consistently been involved in the semiconductor industry business. Heretofore I have been dealing with products such as photomask blanks for EUV lithography and CMP slurries. Currently I am the Head Office’s sales contact for synthetic fused silica glass from the Lithography Department and SiC components from the Thermal Department. AGC's products are components used in the manufacture of semiconductors, and most of our customers are semiconductor manufacturers and semiconductor equipment manufacturers. The principal roles of sales representatives are to accept requests from customers regarding quality, technology, price, and delivery time and to bring in other AGC personnel and steer toward solutions. They are also involved in expanding sales for new applications and to new customers as well as improving internal operations and optimizing organizations for future business development.

Supporting stable supply of semiconductors working as "One Team" with customers

AGC's customers for semiconductor materials are all leading companies worldwide. Requests for quality improvement from customers who lead the industry with cutting-edge technology present difficult challenges, but meeting their expectations offers us great opportunities for us to grow. In particular, the processes used to manufacture the most advanced generation of semiconductors require complex and advanced technologies. Sometimes we encounter situations where we have to solve a problem on the customer's side as soon as possible without knowing the cause of the problem. We feel a great sense of accomplishment when we are able to find a solution to an uncertain situation through repeatedly positing and then verifying hypotheses in unison with our customers.

AGC and its customers are both seeking a stable supply of semiconductors. Our goal remains the same: to support people's lives by working together as "One Team" with our customers.

Semiconductors are in near universal use in electronic devices and home appliances all around us, notably smartphones, PCs, and televisions, and materials developed and manufactured by AGC are used in these devices/appliances.

Being a comprehensive materials manufacturer gives us a wide range of knowledge and expertise

AGC's electronic components are indispensable in the manufacture of all kinds of electrical products we use. Customers’ technical requirements have recently been increasing as smartphones, PCs and other electronic and communication devices relevant to AI, IoT, 5G, electric vehicles and AR/VR have seen remarkable development. Because AGC is a comprehensive materials manufacturer not limited to electronic materials, we have the resources to support our customers by mobilizing our extensive knowledge and experience, and we believe this is a great advantage.

I find it very rewarding to be able to communicate on a day-to-day basis with customers who are on the cutting edge of technology and to see the semiconductors manufactured with the materials I am in charge of being installed in a wide variety of new electronic devices. As a sales representative, I communicate with customers on behalf of the company, bearing in mind the wishes of all the people involved in the manufacturing of our products. I approach my work with a sense of both responsibility and pride.

Improving semiconductor performance is the key to a sustainable society

It is crucial that we as a supplier of electronic components respond to the requests of the electronic device manufacturers that are our customers. It will be even more important in future for us to anticipate the products and functions that our customers and the general public will need and develop the necessary products ahead of time or boost the performance of existing products.

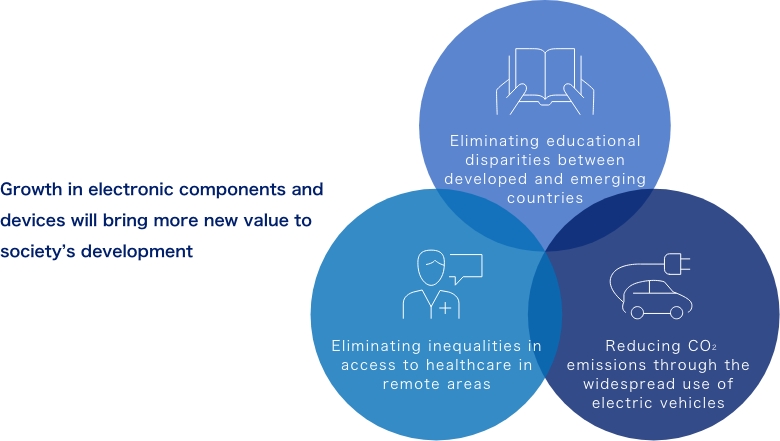

I believe that the growth of electronic components and devices can bring more new value to society’s development. As the technology for communicating information progresses, it will become possible to convey at one time larger amounts of information over greater distances in a more stable manner. Information will become equally available in developed and emerging countries, helping to eliminate disparities in education. In the medical and agricultural spheres, the development of IoT technology will enable remote and highly precise management. The improved accuracy of automated driving will also create a safer traffic environment, while the widespread use of electric vehicles will help to curb CO2 emissions.

It is no exaggeration to say that the key to all of these developments will be improvements to semiconductor performance. As people's lifestyles and values change dramatically in the wake of the recent pandemic and the growing focus on sustainable societies, the performance requirements for electronic components are also changing. We believe that we can contribute to the world more than ever not only by meeting these demands but also by proposing various possibilities that transcend our perspective as a materials supplier. Leveraging the strength that comes with being a comprehensive materials manufacturer and collaborating on chemicals, glass and other technologies other than electronic components should enable us to make a greater contribution to the world.