Addressing food crises

In this era of frequent climate change-induced natural disasters, stable food production is a global challenge. AGC's proprietary technology for the ethylene-tetrafluoroethylene (ETFE) film F-CLEAN® (hereinafter, "F-CLEAN") helps control solar energy and realize efficient and eco-friendly horticultural facilities. Here we will introduce some of the challenges faced by employees involved in this product’s development.

Confronting the world's food problems through effective use of solar energy with F-CLEAN ETFE film

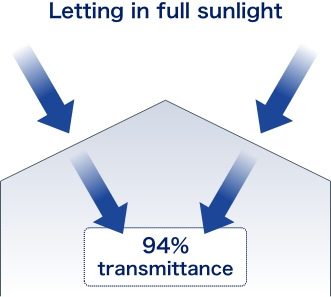

F-CLEAN ETFE film freely controls solar energy, allowing almost the same amount of light in greenhouses as in open field cultivation, helping achieve eco-friendly and efficient horticulture in greenhouses. This new material, which transcends the concept of existing covering materials, has been nicknamed "unbreakable glass" overseas. It minimizes damage caused by typhoons and earthquakes, thereby protecting growers and crops from natural disasters. Its outstanding durability means that it shows almost no sign of deterioration even after 30 years. This leads to lower maintenance costs, greater energy savings, and reduced damage from disasters.

The total light transmittance of F-CLEAN is approximately 94% (F-CLEAN natural light at 60 μm). This increases crop yields and enables stable year-round cultivation.

It can be used in all types of meteorological environments, from extremely cold to scorching tropical regions, freely controlling heat and light and thereby contributing to local production for local consumption.

Professional, Polymer Product Development Office, Basic Technologies Department, Chemicals Company

Focusing on the development of ETFE film optimal for agricultural greenhouses

Agricultural films using ethylene-tetrafluoroethylene (ETFE) were first sold in 1988. Nippon Carbide Industries, which had been selling PVC film for agricultural greenhouses, was the first company in the world to sell this film in this field. F-CLEAN was marketed in 1988 as the industry's first 10-year stretchable film. Membrane structures were first used in the Eden Project (for botanical gardens) in the UK in 2001 and film solar cells were first developed in 1998, but the use of ETFE in agricultural greenhouses in Japan is the first example worldwide of a solar application of ETFE. This agricultural application requires transparency, light transmission, bending resistance, tear resistance, mechanical strength, stain resistance, and ETFE is the best material in these regards. AGC thus has a responsibility to lead the way in horticultural materials.

In 1998, AGC's proprietary UV-cut products were born, completing the F-CLEAN lineup for all vegetables, fruits, and flowers. Since then, AGC has offered products such as F-CLEAN Gray and F-CLEAN Soft Shine for use in barns, eel farming, mushroom cultivation, agricultural warehouses, break rooms, etc.

I myself have been involved in ETFE film product development for about 32 years since 1990. For outdoor applications, a high level of weather durability equivalent to that of ETFE is required, so we operate accelerated weather durability test equipment at full capacity and evaluate the weather durability over a period of approximately two years. In parallel, we also measure the thermal and optical environment in greenhouses and conduct actual cultivation tests to verify the effectiveness of the new film. This step cannot be omitted.

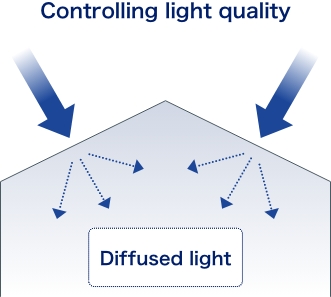

Films that evenly scatter sunlight have become a global trend these past ten years

Conventional transparent clear films for agricultural use have issues with uneven plant growth due to the shade from the greenhouse aggregate and with significant changes in leaf temperature due to ever-varying skies that stress the plants. We therefore embarked on the development of a matte finish film to resolve these issues. The development team imported omnidirectional quantum scalar sensor capable of measuring light entering a greenhouse from oblique and side angles. We were thereby able to confirm that, whereas only the top leaves receive light when clear film is used, second- and third-tier leaves also receive light when matte finish film is employed, leading to the conclusion that the overall amount of photosynthesis would remain the same.

For about five years from the product launch in 2008, sales continued to be limited to flower cultivation, which does not require high light intensity. However, the positive cultivation results achieved by farmers who tested the product on vegetables spread slowly and steadily throughout the country by word of mouth until, by 2021, sales of matte finish diffusion film exceeded those of clear film. Diffused light cultivation has now become a global trend, marking a dramatic change over the past ten years.

Omnidirectional light intensity measurements are taken near tomato growing points (photo: Diffused light from spring to fall, clear light by condensed water in winter). This improved diffusion UV cut film is the latest type of film that precisely controls light diffusion angles, allowing us to measure light intensity and light quality in greenhouses right in front of growers to expand sales.

ETFE wavelength conversion film is being developed as a film that will overwhelmingly increase crop yields. Dispersing a material that absorbs green light and emits red light within the film makes it possible to increase the red-wavelength light, which is most effective for photosynthesis, above that contained in sunlight. An example of this effect is shown in the results for onions. The photo shows the exterior of the film in its initial stage (2007) and the interior 11 years later (lower left: comparison of onions in the full-light transmission and wavelength conversion sections by Kochi University). F-CLEAN must maintain this wavelength conversion function for an extended period and, after 11 years of outdoor exposure, this function has only decreased to about 50% of its initial level.

Providing materials that lead to stable food supply and increased income for producers

The ETFE film used for F-CLEAN has high tearing strength and impact resistance. It is a cover material that can be said to be less susceptible to damage from natural disasters such as typhoons than other materials, including glass. It is a material that can be used for a long period of time as long as the film does not flap while fixed to the greenhouse, with only a 10% decrease in its optical and mechanical properties over a 30-year period.

Because it can create an environment in which light intensity and quality remain the same year after year, it is also the ideal material for "smart agriculture" in which farmers can apply the know-how they have garnered through cultivation (on light intensity, temperature, humidity, CO2, and irrigation water) to make automatic adjustments. We are convinced that this material can contribute to increased food production, stable supply, and increased income for farmers.

Since there is less re-covering required, the amount of plastic needing to be recycled is also significantly reduced. Customers who purchase F-CLEAN are demonstrating the willingness to invest in the film for the next 10 to 30 years. Whenever I visit farmers, I am greatly inspired by their commitment to yield and quality, their balanced approach to incorporating the latest cultivation methods, and their passion for their work.

The benefits of sunlight brought by ETFE film enrich our lives

As cultivation technology advances, there will continue to be a need for covering materials that contribute to even more efficient photosynthesis. The ETFE wavelength conversion film currently under development can provide sufficient red light effective for photosynthesis even in mountainous areas with low solar radiation. Once this is commercialized, it will be possible to procure food from land on which cultivation has been abandoned. In fact, there have been reports of increased yields with ETFE wavelength conversion film and of examples of irradiation by small amounts of light at specific wavelengths stimulating key photosynthetic points to increase yields. Incorporating the discoveries of biochemical reactions in plants reported by universities and other material manufacturers into the development of new ETFE films is one of the roles we are expected to play.

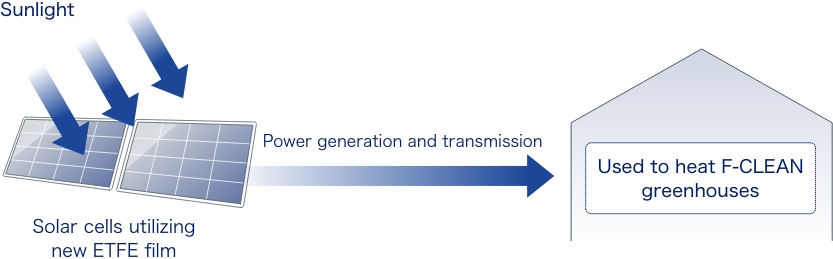

We believe that greenhouse specifications with improved heat Insulation will become even more important in future for reducing the heating of greenhouses in winter. F-CLEAN double-covered greenhouses maintain high visible-light transmittance (a value indicating the amount of light taken in) while reducing the thermal transmittance (a value indicating the ease of heat transfer that takes into account the thickness of the material) by about half. This is why vegetables are grown in greenhouses using ETFE film in Yakutsk, Russia, where temperatures can drop to as low as -40°C. The use of ETFE film as a surface material for lightweight film solar cells is also expanding rapidly, and there is a growing possibility that electricity produced by such solar cells will be used to heat F-CLEAN greenhouses in winter. If fertilizers are excluded, crops are aggregates of the energy derived from the sun’s light, heat, and power, and ETFE film can support sustainable agriculture using solar energy even when it comes to power.

Agricultural greenhouses are man-made structures, but the greenery grown there provides people with enrichment and hope and creates landscapes that local people want to preserve. Greenhouses are truly material and spiritual bastions that help keep people living, and we are pursuing development with this in mind.