Using resources

effectively

THERMOTECT WALL™ (hereinafter, "THERMOTECT WALL"), which contributes to energy conservation and environmental improvement in industrial furnaces, received the Agency for Natural Resources and Energy Commissioner's Award (Product & Business Model Category) at the Energy Conservation Grand Prize in fiscal 2015. Proposals have been made that meet the conditions and needs of customers’ equipment and operations. Let’s hear the thoughts and future prospects of an employee who has been working to expand sales channels for this product, which contributes to environmental protection.

Energy-saving effects and environmental considerations to realize safety and reduced operating cost for industrial furnaces

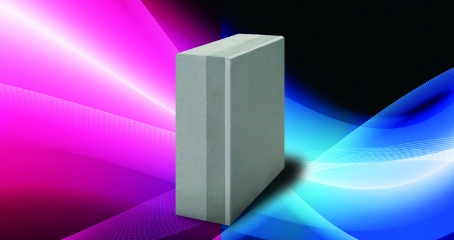

High thermal insulation ceramics wall for furnace of “THERMOTECT WALL™” is composed of multiple layered of “Thermotect™” which has the properties of high thermal insulation and high temperature resistance, and can be used up to the maximum service temperature of 1,700°C. This was launched by utilizing special raw material developed in-house by AGC.

Since “THERMOTECT WALL” does not contain any refractory-ceramics-fiber (hereinafter, RCF)*, it contributes to an improved hygienic environment for workers during furnace installation and demolition work. It has the advantage that it can be used in areas physically and chemically damaged where RCF could not conventionally be applied. In fiscal 2015, it received the Agency for Natural Resources and Energy Commissioner's Award (Product & Business Model Category) at the Energy Conservation Grand Prize organized by the Energy Conservation Center, Japan (supported by the Ministry of Economy, Trade and Industry) in recognition of the business model for energy-saving solutions with optimal designs according to the operating conditions of various industrial furnaces.

*Since it is a substance that may cause health hazards, it was designated a Class II substance (special controls) in November 2015.

Its high energy-saving performance and environmental safety contribute to cost reductions for industrial furnaces. It combines high heat insulation and high heat resistance, and can be used in metal melting furnaces.

Manager, Corporate Strategy Office, AGC Ceramics Co., Ltd.

Growing environmental and health awareness led to the development of "THERMOTECT WALL"

AGC Ceramics is advancing company-wide development of solutions that contribute to global environmental protection and energy conservation under the theme of "Earth Saving." In 2008, we launched the development of "THERMOTECT," which is the predecessor and now a component of "THERMOTECT WALL" and has high heat insulation and high heat resistance, and sales officially began in 2010. Behind the development was the idea that we might be able to use waste materials generated in manufacturing processes as recycled raw materials.

When it was first launched on the market, the number of products was small and the potential applications were limited, but we kept going with marketing and product development. Meanwhile, as a major change in the external environment, RCF regulations came into effect in November 2015, which further boosted the need for environmentally and health-friendly "THERMOTECT" that does not include RCF. We developed the concept of "THERMOTECT" as a solution that engages with these environmental changes and contributes to solving social issues and decided to launch "THERMOTECT WALL" in 2013. I have participated in the project from the launch and start of THERMOTECT, and have been involved in strategy formulation as a sales leader. Currently, I’m working with marketing and sales in the refractory market.

Delivering results as proposed. Gaining trust from customers

When “THERMOTECT” was first created, customers had expectations on refractory based on "price" and "durability," so the number of customers who expected energy saving from such materials was extremely limited. Since "THERMOTECT" uses special raw materials, the product price is higher than those of common refractory. Even when we suggested the added value of energy saving, people might take an interest but would rarely opt for it. I realized how difficult it is to help them to understand a product concept that has never been seen before and the pain of giving birth.

Even so, we had a strong feeling that this product would definitely be useful to customers and society. We revised our target demographic to customers with high environmental awareness and made changes to how we present the product as well. In addition to qualitative information, we also created materials with added quantitative data of various kinds, such as specific figures showing the effect of reducing CO2 emissions and the effect of reducing fuel consumption and fuel cost. As a result of these efforts, the number of sales gradually increased. If customers use it and can really experience the results as proposed, they come back for more. We got that kind of virtuous cycle. We were very happy that our consistent efforts were recognized, for example with the Energy Conservation Grand Prize in 2015.

Wanting to spread "THERMOTECT WALL" in society and increase contributions to environmental protection

"THERMOTECT" and "THERMOTECT WALL" are not yet widely used in society. However, we feel that we are able to provide our customers with value such as high energy-saving performance, CO2 reduction, and environmental impact reduction that can’t be obtained with conventional refractory products. In recent years, social environmental awareness has further increased, including efforts to achieve carbon neutrality. The number of places where we can provide value through "THERMOTECT WALL" will continue to expand, and as sales expand, our contributions to global environmental protection will become stronger. I’m hopeful for the future and want to go ahead with promotion activities more than ever.

Creating new solutions and building a society that supports affluent living

Refractory products, including "THERMOTECT WALL," are used in high-temperature plants that emit CO2. However, in the future, we will be switching from fossil fuels to CO2-free fuels, and it is highly likely that the characteristics and requirements of refractory will change in the process.

In response to such changes in society and customer needs, there is a growing possibility that we may create "New THERMOTECT WALL." Or maybe we’ll see the birth of a completely different concept solution that solves a social problem. No matter how our lives change, we want to contribute to the realization of a sustainable society where people can live affluently, with peace of mind, and with a smile at all times.