Examples of New Product Development through the Integration of Core Technologies

Cover glass for car-mounted displays (Technical element : A,C,E,G,I,J,K,L)

AGC will propose a new cockpit UI and UX to deliver safer and more comfortable mobility. Drivers can experience the cockpit of the future, where the thin, deeply curved large-format display, which creates a seamless integration between the display and cockpit for an exceptional design. Lightweight, flexible, and scratch-resistant chemically tempered glass enables deeply curved display cover glass (A,I, J). Surface treatment reduces reflection and glare to improve visibility while also making the surface fingerprint-resistant and smooth for easy operation (C, E, G, K, L). AGC has pioneered product development through the fusion of glass and chemistry, earning a leading market share as its innovations are increasingly adopted in a wide range of vehicles.

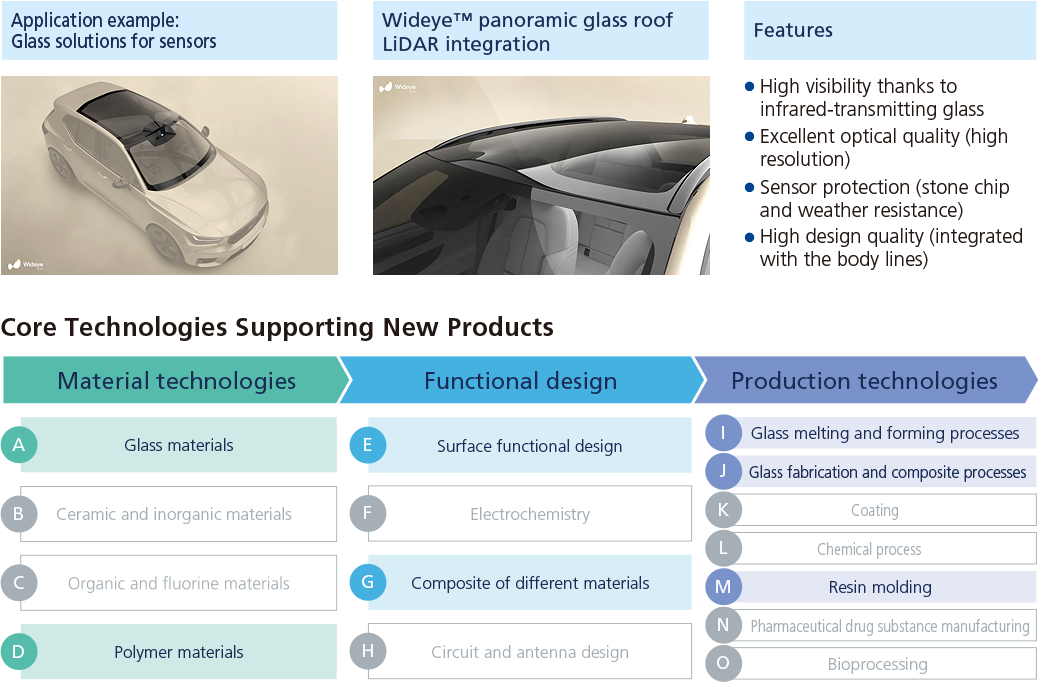

Glass solutions for sensors (Technical element: A,D,E,G,I,J,M)

To improve autonomous driving and safety, AGC offers various Wideye*1 LiDAR*2 integration solutions, including LiDAR cover glass that incorporates LiDAR units into roof glass to achieve seamless body lines as well as a type that integrates LiDAR and multiple cameras inside the vehicle. Space is secured for integrating LiDAR units by forming and processing roof glass, which has been increasing in size in recent years. At the same time, it integrates seamlessly with the windshield to create a sleek, unified body line (A,I, J). The section housing the LiDAR unit is integrally molded with resin and window material that transmits near-infrared light (D,E,G, M). Based on our long-standing relationships with our customers, we are able to quickly understand their needs and provide solutions that combine the required functionality and design, something only a materials company AGC can offer.

*1 Cover glass for LiDAR *2 Light Detection and Ranging

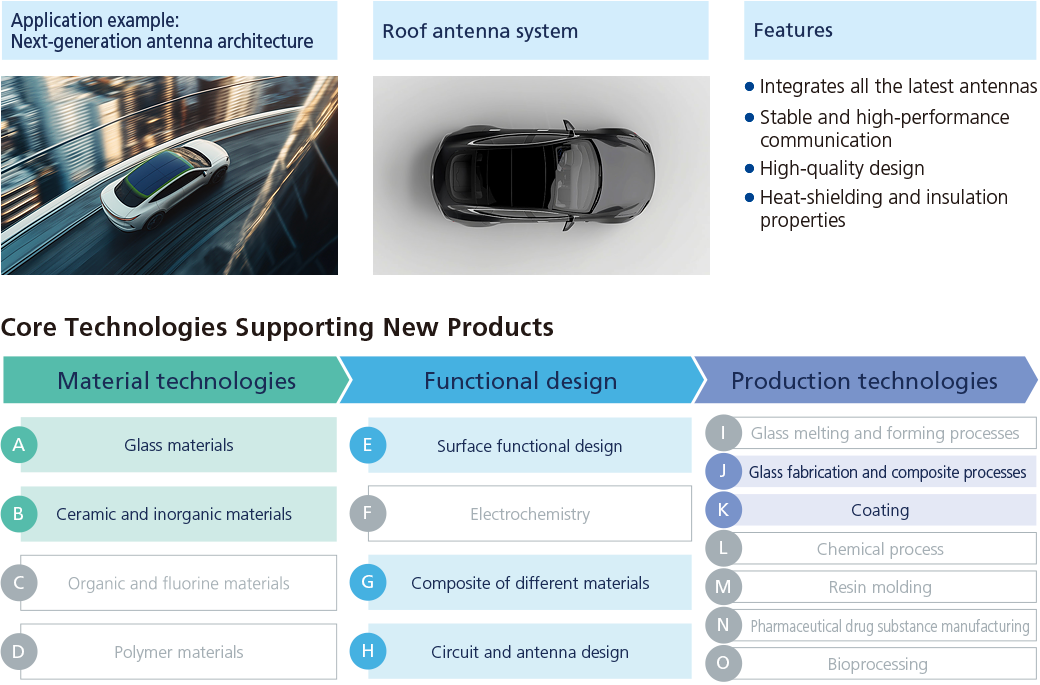

Next-generation antenna architecture (Technical element :A,B,E,G,H,J,K)

To ensure constant connectivity and reliable data exchange, vehicles require high-performance, highly reliable wireless communication technology. AGC is proposing next-generation antenna system that seamlessly integrates an antenna inside the roof glass, achieving both stable communication performance and streamline body design. These are the result of a combination of materials, design, and evaluation technologies (A, B, E, G, H, J, K) cultivated through many years of product development with customers. AGC's integrated antenna system pushes the boundaries of vehicle connectivity from 5G to SatCom and beyond.

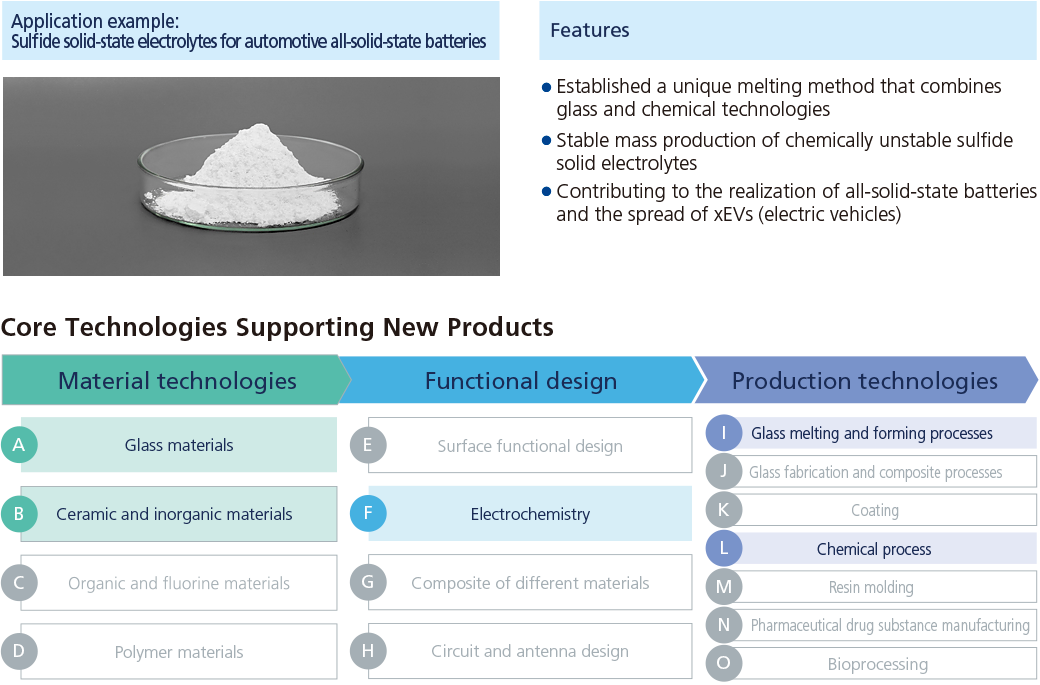

Sulfide solid-state electrolytes used in all-solid-state batteries (Technical element A,B,F,I,L)

AGC aims to contribute to the widespread adoption of xEVs (electrified vehicles) equipped with all-solid-state batteries by ensuring a stable supply of sulfide solid-state electrolytes. The widespread use of all-solid-state batteries (ASSBs), which have high energy density, short recharge times, and are flame-retardant, will make xEVs (electrified vehicles) safer and more accessible by allowing them to extend their driving range. Sulfide solid-state electrolytes are considered promising materials for all-solid-state batteries for automotive applications, but their mass production has been highly challenging because they are chemically unstable and are difficult to handle. AGC has established a unique melting method that no other company can imitate, combining glass and chemical technologies to enable the mass production of high-quality electrolytes of various compositions (A,B,F,I,L). It will greatly contribute to the practical application and widespread of xEVs (electrified vehicles) equipped with all-solid-state batteries.

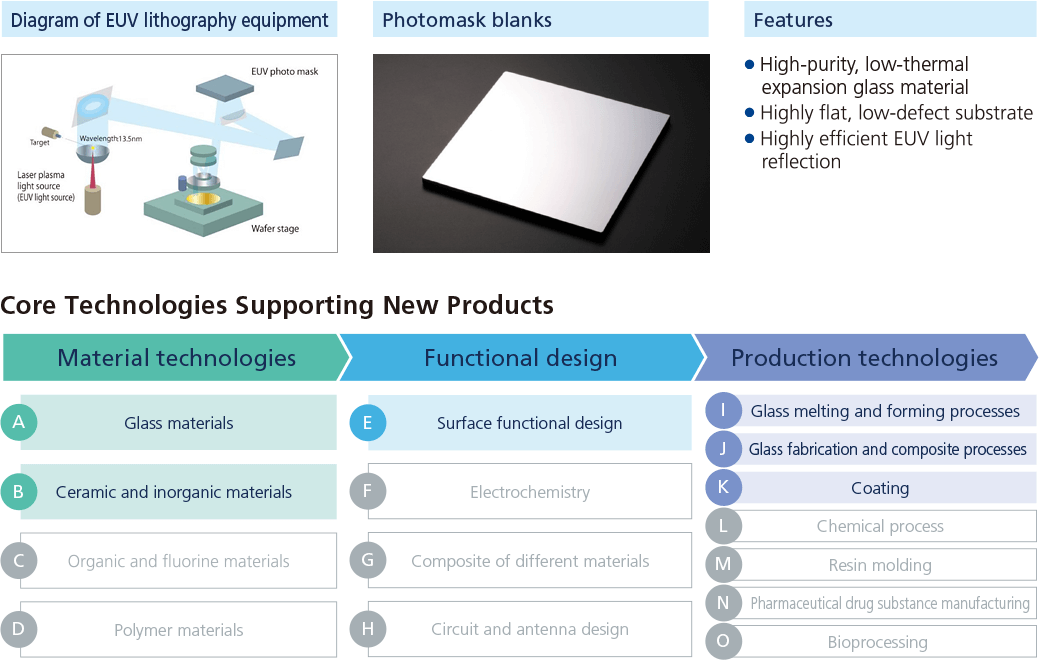

Photomask blanks for EUV lithography (technical element: A,B,E,I,J,K)

The formation of _ne circuits pattern in cutting-edge semiconductor chips is carried out using reflective photolithography technology with extreme ultraviolet (EUV) light, which has a wavelength (13.5 nm) less than one-tenth that of conventional exposure using excimer laser light (193 nm). As a result, the precision required for photomask blanks has drastically become ten times stricter. AGC has developed this technology by combining and upgrading elemental technologies such as: high-purity glass material design technology and manufacturing process technology with uniformity and minimal thermal expansion (A, I); high-precision polishing and cleaning technology for the production of photomask blanks substrates (B, J); and optical thin _lm design technology that efficiently reflects EUV light and the coating technology to realize it (E, K).

Photomask blanks for EUV lithography

Photomask blanks for EUV lithography that enable miniaturization of semiconductor chip circuits pattern to achive larger data capacity and greatoer integration

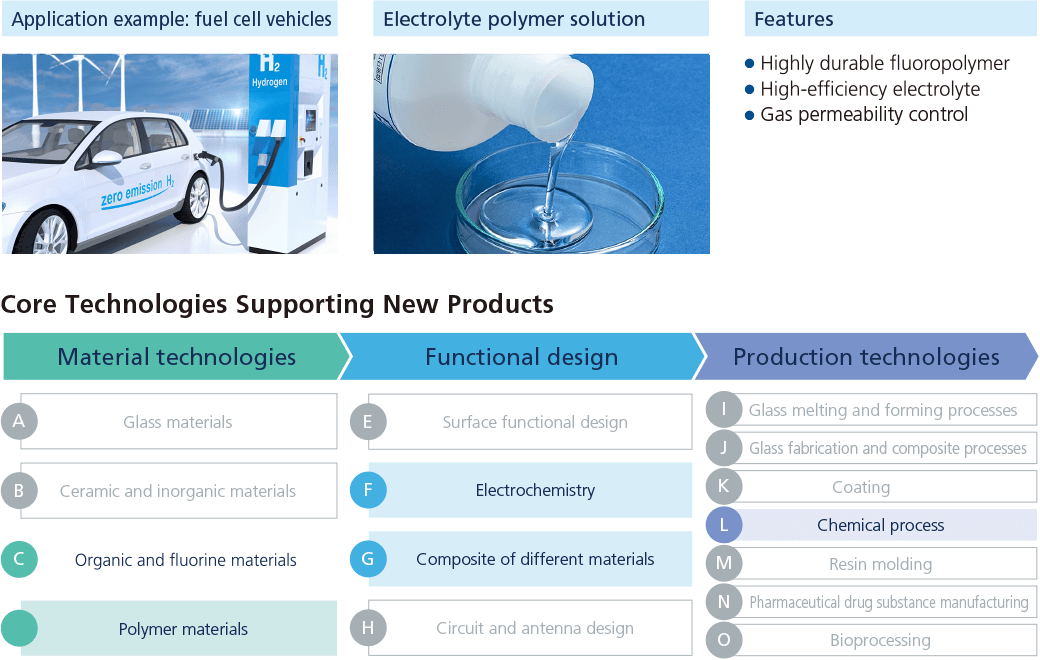

Fluorine-based electrolyte polymers (technical element: C,D,F,G,L)

The use of hydrogen is expected to contribute to the realization of a sustainable global environment. The key material is AGC’s FORBLUE™ series of fluorine-based electrolyte polymers.

The FORBLUE™ S-SERIES of fluorine based ion-exchange membranes suitable for green hydrogen production can be used to convert renewable energy, such as solar and wind power generation, into hydrogen through water electrolysis for storage and transportation. The FORBLUE™ i-SERIES of electrolyte polymer solutions for fuel cells are used in electrolyte membranes and electrodes of fuel cells to efficiently generate electrical energy from hydrogen and oxygen without emitting CO2. These fluorine-based electrolyte polymers are developed and manufactured by combining AGC’s fluorine materials and polymer material technologies (C, D); electrochemical technology (F); composite technology (G); and chemical process technology (L).

Fluorine-based electrolyte polymers

Key materials for hydrogen energy utilization contributing to the realization of a sustainable global environment: Fluorine-based electrolyte polymers for water electrolysis and fuel cells