Core Technologies: Material Technology

AGC's shared core technologies have been accumulated and deepened over many years. They include highly sophisticated materials technology, functional design technology that yields enhanced functionality through convergence with materials technology, and production technology that enables stable production of high-quality products. Through our efforts to meet customers' expectations and our experience of utilizing various materials, we have also accumulated technologies for designing parts by assembling various materials. We use these technologies to bring out the full potential of materials.

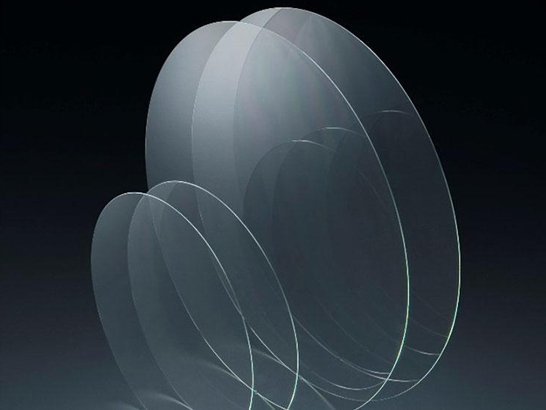

Glass materials

The AGC Group's Glass Business began with the production of architectural glass and automotive glass. Since then, we have expanded our business to encompass a variety of other applications, including flat panel display glass for liquid crystal and organic light-emitting diode (OLED) displays and other devices, cover glass for smartphones, glass for optical components used in image sensors, glass substrates used in semiconductor processing, glass for electronic components, and solid electrolyte glass for ion batteries. AGC is continually enhancing its glass composition design technologies to meet needs in these and other areas. We also make extensive use of advanced analysis and simulation technologies to enhance our understanding of glass at the atomic level so that we can develop new properties based on glass structures. By closely linking these activities with the development of production technologies, we aim to shorten commercialization lead times for new discoveries relating to advanced functional glass.

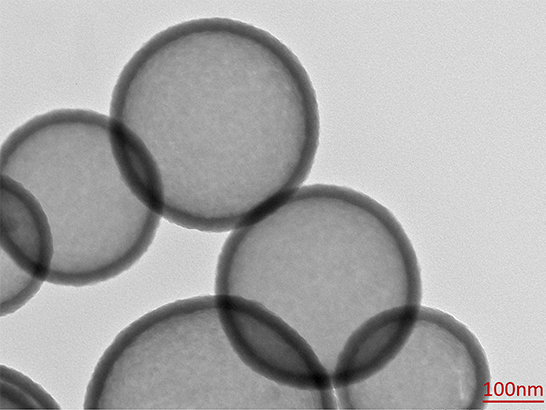

Ceramic and inorganic materials

Using ceramic technology developed over many years, AGC has brought numerous innovations to glass production processes, such as the use of high-grade ceramic refractory materials. We have also provided a wide range of products and solutions that help to protect the global environment. One of our notable achievements was the development of high-purity silicon carbide ceramics, which have been used for over 30 years in components of semiconductor manufacturing equipment employed in high-temperature environments. With the growing popularity of mobile devices and energy-saving products in recent years, these ceramics are also being utilized increasingly in the manufacture of memory and power devices. We aim to offer more new ceramic materials and products for use in a wide variety of fields, such as electronic materials and parts as well as the fine ceramics needed to support the growth of renewable energy utilization.

Our inorganic materials technology, especially wet synthesis of inorganic particles, is contributing to business development based on advanced inorganic products, such as functional silica particles, abrasives for electronic devices, and electronic materials. AGC designs, synthesizes, and analyzes a range of functional materials using technologies based on sol-gel, emulsification, sodium silicate, and other substances and creates various functions by controlling the composition and structure of particle surfaces. In recent years, we have proposed ways to create new value by combining these products with organic materials and resins and exploring ways to achieve enhanced performance by blending them in various coatings. Through these activities, we are contributing to the addition of new functionality to a variety of materials.

Organic and fluorine materials

Fluorine is a key material for the AGC Group. We develop and supply a variety of innovative products that leverage the properties of this substance, using original world-class fluorine-based technology created through the convergence of molecular design with synthesis and polymerization technologies. We have continually used these technologies to provide optimal solutions to meet the needs of our customers in a wide array of fields, especially automobiles, electronics, life sciences, and energy.

Our lineup of heat and chemical resistant fluoropolymers includes electrolyte polymers for use in high-performance fuel cells and water electrolysis, Fluon® ETFE, which boasts one of the largest shares of the global market for fluoropolymers, and highly weather resistant fluoropolymers for paints and coating materials. We also supply environment-friendly refrigerants and solvents, highly durable anti-fingerprint coatings, and an original drug substance for glaucoma treatment, as well as providing contract manufacturing services for pharmaceutical and agrochemical intermediates. We are using the potential of these materials to contribute to the realization of the globally shared goal of creating a sustainable society.

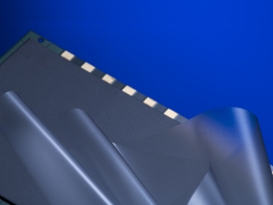

Semiconductor packaging

Polymer materials

AGC's polymer materials range from unique chemical chains to polyether polyol, polyurethane, polyvinyl chloride, and fluoropolymers. We create polymer designs with functions that meet our customers' requirements, while also establishing precision polymerization technologies. Using these functional designs, we strive to control the formulation and compounding of polymer materials for various applications, including foams, coating agents, elastomers, adhesives, and sealants. For example, AGC also offers fluorine chemicals produced through polymerization using tetrafluoroethylene as a key monomer, such as ETFE, as well as perfectly amorphous transparent fluororesins created through cyclopolymerization, such as CYTOP. We are currently developing technology to compound these products with various additives and other resins.