Core Technologies: Production Technology

AGC's shared core technologies have been accumulated and deepened over many years. They include highly sophisticated materials technology, functional design technology that yields enhanced functionality through convergence with materials technology, and production technology that enables stable production of high-quality products. Through our efforts to meet customers' expectations and our experience of utilizing various materials, we have also accumulated technologies for designing parts by assembling various materials. We use these technologies to bring out the full potential of materials.

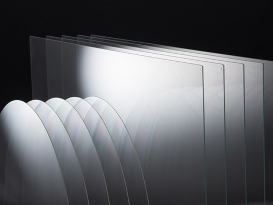

Glass melting and forming processes

Sheet glass is produced by melting precisely formulated combinations of raw materials in melting furnaces. The liquid glass is then pulled and annealed in a continuous process to create sheet glass. The creation of uniformly flat glass without bubbles, inclusions, or distortion requires a scientific understanding of chemical reactions, heat, and mass transfer, combined with precise design and control technologies tailored to the properties of the materials and desired characteristics of the finished products. AGC is continually enhancing the melting and forming process technologies used to produce architectural and automotive glass. We are also refining technologies for the production of specialty products, such as alkali-free glass for displays, and cover glass for smartphones. Our ongoing challenges are to expand our technology base further, to create new value and functions through the development of processes for new types of glass and materials, and to develop processes that will enable us to achieve net-zero emissions of greenhouse gases.

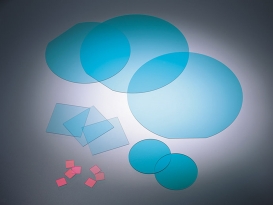

Glass fabrication and composite processes

AGC will continue to create added value through the use of heat forming and other processes to turn glass into the desired designs and shapes, as well as strengthening through heat treatment and ion exchanges, edge processing, drilling, surface flattening and modification, and the creation of microstructures. By forming composites of glass and other materials, such as resins, we are able to offset the weaknesses of glass, such as its brittleness, while maintaining its advantages, including its chemical resistance and gas barrier properties, leading to the production of materials and parts with new functions and values. The processes used to make fabricated and composite products are supported by a wide spectrum of element technologies, including bending and pressing, thermal/chemical strengthening, laser and machine processing, polishing and washing, etching, plasma treatment, 3D printing, and glass-resin laminating and integrated molding. The finished products that emerge from these processes are used widely in interior and exterior automotive glass, display glass, smartphone cover glass, and electronic and optical materials, such as extreme ultraviolet (EUV) mask blanks and lenses. Recently, we have also started to manufacture products for micro devices, including those used in biotechnology fields. We will continue to improve our process technologies in anticipation of changes in market needs and the increasingly sophisticated functions required by users.

Coatings

AGC's coating technologies range from physical vapor deposition (PVD), especially sputtering, and chemical vapor deposition (CVD), to wet coating. Coating technologies can be used to control light transparency, reflection and absorption, electrical properties, water repellence, and hydrophilicity in various materials, such as glass and polymer films. Recently, we have started to use coatings to control electromagnetic waves at frequencies ranging from extreme ultraviolet to microwaves. For example, extreme ultraviolet coating technology is helping to build our business in the strategic area of electronics by enabling us to produce photomask blanks using EUV light with a wavelength of 13.5nm.

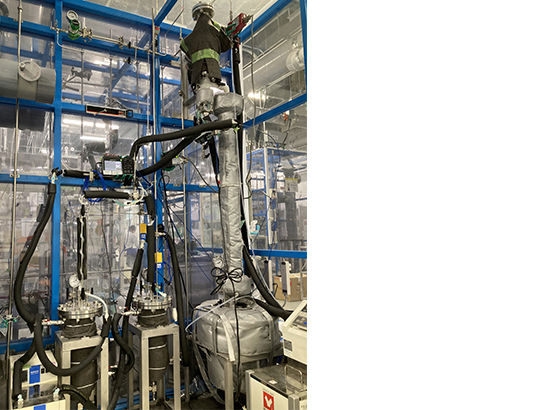

Chemical process

A key feature of AGC's activities in this area is its production of a range of products linked by chemical chains, ranging from basic chemicals produced through the electrolysis of brine containing salt (NaCl), to advanced functional products, such as fluorinated chemicals. Raw and processed materials developed in laboratories are not classed as products until they can be manufactured reliably in actual production facilities. The key indicators of a company's manufacturing expertise are the level of its production systems and it's ability to add value on its production lines. AGC is leading the development of processes for products created using organic and inorganic chemistry and chemical engineering. We have implemented systems to support high standards of safety and quality management and environmental protection. By evolving and deepening our technologies, which include highly original cutting-edge technologies with reduced environmental loads, we have continued to create products that contribute to progress in such fields as mobility, electronics, life sciences, and the environment.

Resin molding

We have developed injection molding technologies used to integrate different resin materials or glass and resin materials, including extrusion and heat lamination technologies for fluoropolymer films. We are also deepening our knowledge of roll-to-roll coating and combining/laminating technologies to meet the need for glass and resin composites and materials with additional functions. In addition to the creation of materials, we also add value and functionality through shaping. We offer various molding and fabricating technologies for use in the development of new products in the fields of mobility and electronics.

Pharmaceutical drug substance manufacturing

Through its business as a contract development and manufacturing organization (CDMO), AGC is helping people to enjoy good health. We manufacture pharmaceuticals ranging from small-molecule substances to biopharmaceuticals and develop manufacturing process technologies under contract on behalf of other companies. To support this business and enable us to supply highly effective and consistently high-quality active pharmaceutical ingredients, we have created a good manufacturing practice (GMP) structure covering all stages from the intake of raw materials to the manufacture and shipment of finished products. We respond to the needs of our customers through activities that comply with GMP requirements from the process development stage.

Bioprocessing

Proteins are used for applications ranging from biopharmaceuticals to industrial enzymes. AGC has developed the technologies required to manufacture proteins, including genetic modification, microorganism and mammalian cell culturing, protein refining and analysis. The manufacture of pharmaceuticals from proteins requires advanced technology. AGC is using its extensive resources of protein-related knowledge and expertise to develop its contract development and manufacturing business as a CDMO specializing in active ingredients for biopharmaceuticals. Our genetic modification technology plays an extremely important role in the creation of the cell lines required to produce target substances. AGC has a long track record of successful development in recombinant proteins from various hosts, including AGC's unique schizosaccharomyces pombe expression system (ASPEX), which uses fission yeast as host cells. We are also working to enhance our genetic modification technology, which incorporates our knowledge of omics analysis and information science. Our culturing technology, which is based on our wide-ranging experience of culturing e-coli, yeast, and CHO cells, enables us to produce large quantities of microorganisms and mammalian cells and is essential for the production of various biologically-derived products. We are also developing culturing technology for human stem cells, including human iPS stem cells and human mesenchymal stem cells for use in new treatment modalities, such as cell therapy and regenerative medicine. In addition to their contribution to our biopharmaceutical CDMO business, we also hope to apply technologies to the creation of resource-efficient production processes based on bioprocess.